When material failure is not an option, industries like aerospace, advanced manufacturing, and electronics rely on argon gas for their high-temperature furnace operations. Argon’s chemically inert nature prevents unwanted reactions, such as oxidation, that would otherwise compromise the strength, purity, and performance of mission-critical components during heat treatment.

The decision to use argon is not about choosing a gas; it's about guaranteeing material integrity. Its higher cost is a direct investment in quality and reliability, ensuring that high-performance materials are not weakened or contaminated during fabrication.

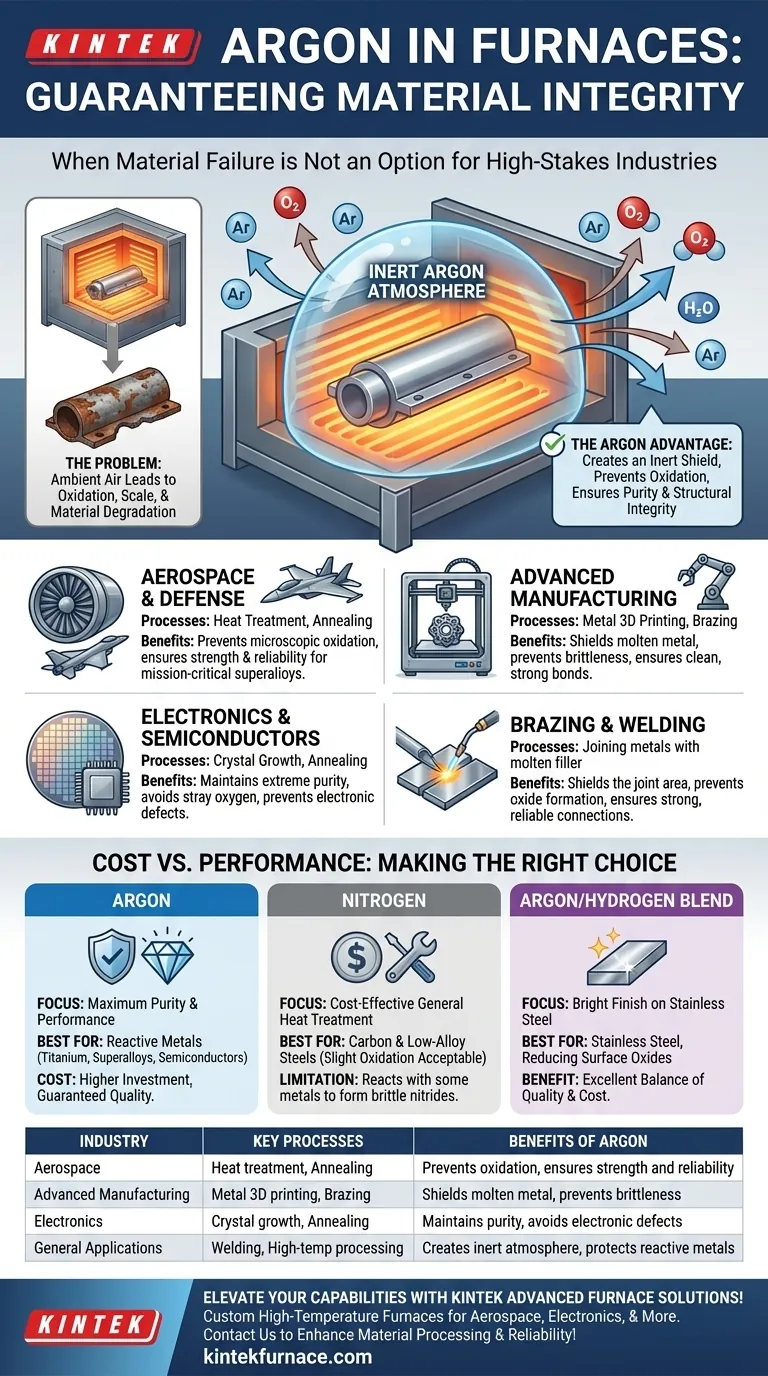

The Fundamental Role of Argon: Creating an Inert Atmosphere

At its core, the value of argon lies in what it doesn't do. As a noble gas, it is almost completely non-reactive, which is a critical feature for high-temperature material processing.

Why an Inert Atmosphere Is Critical

At elevated temperatures, most materials become highly reactive. When exposed to ambient air, which is nearly 21% oxygen, metals will rapidly oxidize. This process creates scale on the surface, can alter the material's chemical composition, and ultimately degrades its mechanical properties.

An inert atmosphere displaces the reactive oxygen and moisture from the furnace, blanketing the workpiece in a stable, non-reactive environment.

The Problem with Air and Other Gases

Using ambient air in a furnace is essentially a controlled corrosive process. Argon, by contrast, acts as a protective shield. It ensures that the only changes happening to the material are the ones intended by the heat treatment process itself, not unpredictable chemical reactions.

Ensuring Purity and Structural Integrity

For alloys used in aerospace or medical implants, the precise chemical balance is what gives them their unique properties, like heat resistance or biocompatibility. Argon prevents elements from being stripped out of or added to the alloy, ensuring the finished part meets its exact design specifications.

Key Industrial Applications and Processes

The need for absolute material purity drives argon's use across several high-stakes industries. While many sectors use heat, only those with the most stringent quality demands justify the use of argon.

Aerospace and Defense

Components like turbine blades, landing gear, and engine components are forged from advanced superalloys. During the heat treatment and annealing processes, argon prevents microscopic oxidation that could lead to stress fractures and catastrophic failure in service.

Advanced Manufacturing and Metal 3D Printing

In metal additive manufacturing (3D printing), a high-power laser melts fine metal powder layer by layer. An argon atmosphere is essential to shield the tiny pool of molten metal from oxygen, which would otherwise cause it to oxidize instantly, resulting in a brittle and useless part.

Electronics and Semiconductors

The production of silicon wafers and other semiconductor components requires extreme purity. Argon is used during crystal growth and annealing to create a perfectly inert environment, as even a few stray atoms of oxygen could ruin the electronic properties of an entire batch.

Brazing and Welding

Brazing is a process that joins two pieces of metal using a molten filler material. Argon shields the joint area from the air, preventing the formation of oxides that would create a weak, brittle bond. This ensures a clean, strong, and reliable connection.

Understanding the Trade-offs: Cost vs. Performance

Argon is highly effective, but it comes at a price. Its selection is a deliberate engineering decision based on a clear understanding of its benefits and costs compared to alternatives.

The Cost Factor

Argon is more expensive to produce and supply than other industrial gases, most notably nitrogen. For many general-purpose heat treatments where slight surface oxidation is acceptable or can be cleaned off later, nitrogen is a more economical choice.

When Nitrogen Isn't Enough

While largely inert, nitrogen can react with certain metals at high temperatures, including titanium, aluminum, and some high-alloy steels. This reaction forms nitrides, which can make the material brittle. Argon does not have this limitation, making it the only safe choice for processing these reactive metals.

The Solution of Gas Mixtures

For some processes, like the heat treatment of stainless steel, a mixture of argon and hydrogen can be used. The argon provides the bulk inert atmosphere, while the hydrogen actively reduces (cleans) any surface oxides that may be present, resulting in a bright, clean finish at a potentially lower cost than pure argon.

Making the Right Choice for Your Goal

Selecting the correct furnace atmosphere is a critical decision that directly impacts product quality, cost, and reliability. Your choice should be guided by the material being processed and the performance demands of the final application.

- If your primary focus is maximum purity and performance: For reactive metals like titanium, superalloys, or semiconductor-grade materials, pure argon is the non-negotiable standard.

- If your primary focus is cost-effective general heat treatment: For most carbon and low-alloy steels where slight surface changes are tolerable, nitrogen is the more economical and practical solution.

- If your primary focus is a bright finish on stainless steels: An argon/hydrogen blend can offer an excellent balance of quality and cost, delivering a clean result without the full expense of pure argon.

Ultimately, the choice of furnace atmosphere is a direct reflection of the quality and reliability you are committed to delivering in your final product.

Summary Table:

| Industry | Key Processes | Benefits of Argon |

|---|---|---|

| Aerospace | Heat treatment, Annealing | Prevents oxidation, ensures strength and reliability |

| Advanced Manufacturing | Metal 3D printing, Brazing | Shields molten metal, prevents brittleness |

| Electronics | Crystal growth, Annealing | Maintains purity, avoids electronic defects |

| General Applications | Welding, High-temperature processing | Creates inert atmosphere, protects reactive metals |

Elevate your laboratory's capabilities with KINTEK's advanced furnace solutions! Leveraging exceptional R&D and in-house manufacturing, we provide high-temperature furnaces like Muffle, Tube, Rotary, Vacuum & Atmosphere, and CVD/PECVD Systems. Our deep customization ensures precise fit for your unique needs, whether in aerospace, electronics, or advanced manufacturing. Don't compromise on quality—contact us today to discuss how our expertise can enhance your material processing and reliability!

Visual Guide

Related Products

- 1200℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1400℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

- Mesh Belt Controlled Atmosphere Furnace Inert Nitrogen Atmosphere Furnace

- Controlled Inert Nitrogen Hydrogen Atmosphere Furnace

People Also Ask

- What does inert mean in furnace atmospheres? Protect materials from oxidation with inert gases.

- How does the inert atmosphere heat treating process work? Prevent Oxidation for Superior Material Quality

- What is nitrogen used for in a furnace? Prevent Oxidation and Control Heat Treatment Quality

- How does nitrogen atmosphere heat treatment improve surface strengthening? Enhance Durability and Performance

- What is the main purpose of heat treatment? Transform Metal Properties for Superior Performance