In material science research, an atmosphere furnace is a critical tool used to heat materials within a precisely controlled gaseous environment. Unlike a standard furnace that operates in ambient air, this specialized equipment allows researchers to prevent unwanted chemical reactions like oxidation, introduce specific reactive gases to modify a material's surface or composition, and synthesize entirely new materials with unique properties under pristine conditions.

The core function of an atmosphere furnace is to decouple heat treatment from the reactive effects of air. This control over the chemical environment is as critical as control over temperature, transforming the furnace from a simple oven into a precise instrument for manipulating a material's fundamental chemistry and structure.

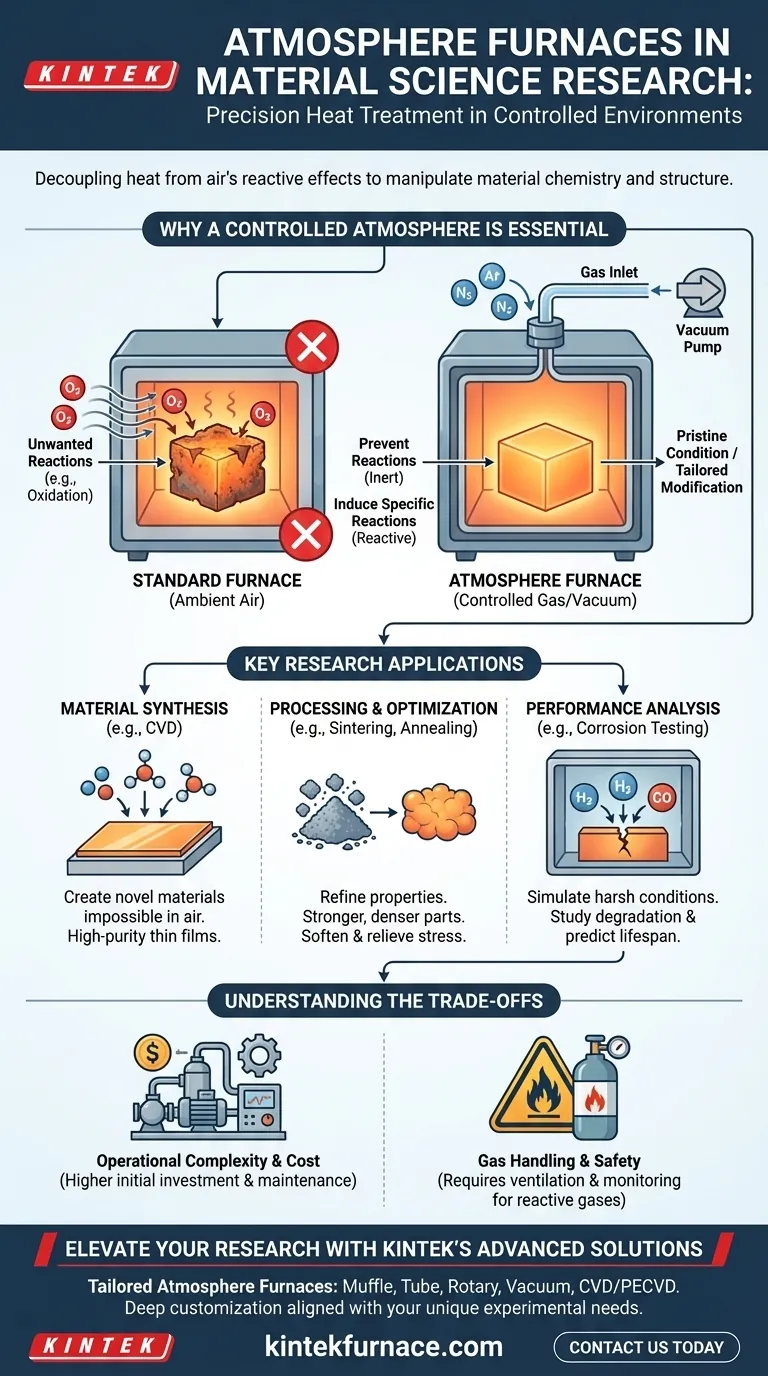

Why a Controlled Atmosphere is Essential

In high-temperature material processing, the surrounding air is not a neutral bystander; it is a highly reactive chemical agent. An atmosphere furnace gives researchers direct control over this crucial variable.

To Prevent Unwanted Reactions

Most materials, especially metals, will rapidly oxidize when heated in air. This forms an oxide layer that can degrade mechanical properties, alter electrical conductivity, and prevent effective bonding or sintering.

By replacing the air with an inert gas like argon or nitrogen, or by creating a vacuum, the furnace provides a clean, non-reactive environment. This ensures that the observed changes in the material are a result of the heat treatment alone, not from unintended chemical contamination.

To Induce Specific, Desired Reactions

Conversely, researchers can intentionally introduce a specific, controlled atmosphere to achieve a desired chemical change. This is a foundational technique for modifying and engineering materials.

For example, introducing a nitrogen-rich atmosphere is used for nitriding, a process that hardens the surface of steel. Using a carbon-rich atmosphere is central to carburizing. These are not side effects; they are the primary goal of the heat treatment.

Key Research Applications

By controlling both temperature and atmosphere, researchers can perform a wide range of experiments to create, test, and optimize materials.

Material Synthesis and Creation

Atmosphere furnaces are essential for synthesizing advanced materials that cannot be made in open air.

Processes like Chemical Vapor Deposition (CVD) rely on introducing precise precursor gases into the furnace, which then react and deposit as a thin, high-purity film onto a substrate. This requires a pristine, controlled environment to avoid impurities that would ruin the final product.

Material Processing and Optimization

These furnaces are used to refine the properties of existing materials.

Sintering is a key example, where powdered materials (like ceramics or metals) are heated to bond together into a solid mass. Performing this in an inert atmosphere prevents oxidation between the powder grains, resulting in a much stronger, denser final part. Other common processes include annealing to soften materials and relieve internal stress, and hardening to increase strength.

Performance and Failure Analysis

Researchers use atmosphere furnaces to simulate the harsh service conditions a material might face in its intended application.

By exposing a material to a specific corrosive gas at high temperatures, scientists can study its oxidation resistance and corrosion behavior. This data is vital for understanding material degradation mechanisms and predicting the lifespan of components used in jet engines, power plants, or chemical reactors.

Understanding the Trade-offs

While indispensable, atmosphere furnaces introduce complexities not found with standard equipment.

Operational Complexity and Cost

These systems are inherently more complex and expensive than simple air furnaces. They require vacuum pumps, gas delivery systems, flow controllers, and safety interlocks, all of which increase initial cost and maintenance requirements.

Gas Handling and Safety

The use of process gases introduces significant safety considerations. Flammable gases like hydrogen require specialized ventilation and leak detection, while inert gases can pose an asphyxiation hazard in poorly ventilated spaces. Proper training and infrastructure are non-negotiable.

Sample Throughput

Many research-grade atmosphere furnaces, especially tubular furnaces, are designed for processing small, high-value samples with extreme precision. They are not typically suited for large-scale or high-throughput production, which remains the domain of industrial-sized equipment.

Applying This to Your Research Goal

Your specific use of an atmosphere furnace will depend entirely on what you aim to achieve.

- If your primary focus is developing novel materials: You will use the furnace for synthesis, leveraging techniques like CVD in a vacuum or carrier gas to control composition and structure with high precision.

- If your primary focus is improving existing alloys or ceramics: You will use the furnace for heat treatments like annealing or sintering in an inert atmosphere to enhance mechanical properties without introducing defects.

- If your primary focus is predicting material lifespan: You will use the furnace as a simulation chamber, exposing samples to controlled corrosive atmospheres to accelerate and study degradation.

Ultimately, an atmosphere furnace elevates heat treatment from a brute-force process to a sophisticated method of chemical and structural engineering.

Summary Table:

| Application | Key Function | Atmosphere Type |

|---|---|---|

| Material Synthesis | Create new materials via CVD | Vacuum or Reactive Gas |

| Material Processing | Sinter powders, anneal metals | Inert Gas (e.g., Argon) |

| Performance Analysis | Test oxidation and corrosion | Corrosive or Controlled Gas |

Elevate your material science research with KINTEK's advanced high-temperature furnace solutions! Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with tailored atmosphere furnaces, including Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures precise alignment with your unique experimental needs, whether you're synthesizing novel materials, optimizing alloys, or analyzing performance. Contact us today to discuss how our solutions can enhance your research efficiency and outcomes!

Visual Guide

Related Products

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1200℃ Controlled Inert Nitrogen Atmosphere Furnace

- Mesh Belt Controlled Atmosphere Furnace Inert Nitrogen Atmosphere Furnace

- 1400℃ Controlled Inert Nitrogen Atmosphere Furnace

- Controlled Inert Nitrogen Hydrogen Atmosphere Furnace

People Also Ask

- Can box type high-temperature resistance furnaces control the atmosphere? Unlock Precision in Material Processing

- How do argon and nitrogen protect samples in vacuum furnaces? Optimize Your Thermal Process with the Right Gas

- How does the pressure range change under vacuum conditions in an atmosphere box furnace? Explore Key Shifts for Material Processing

- How does a mixed gas flow control system maintain stability during high-temperature nitriding? Precision Gas Ratios

- What are the primary inert gases used in vacuum furnaces? Optimize Your Heat Treatment Process