In short, retort furnaces are indispensable across a wide range of industries, most notably metallurgy, ceramics, electronics, and chemical processing. Their value extends deeply into foundational research and development, making them a staple in universities and scientific institutes that work with advanced materials.

The versatility of a retort furnace comes not just from its ability to generate high heat, but from its power to precisely control the gaseous atmosphere during heating. This atmospheric control is the critical factor that enables the creation of pure materials, the joining of complex components, and the execution of specific chemical reactions.

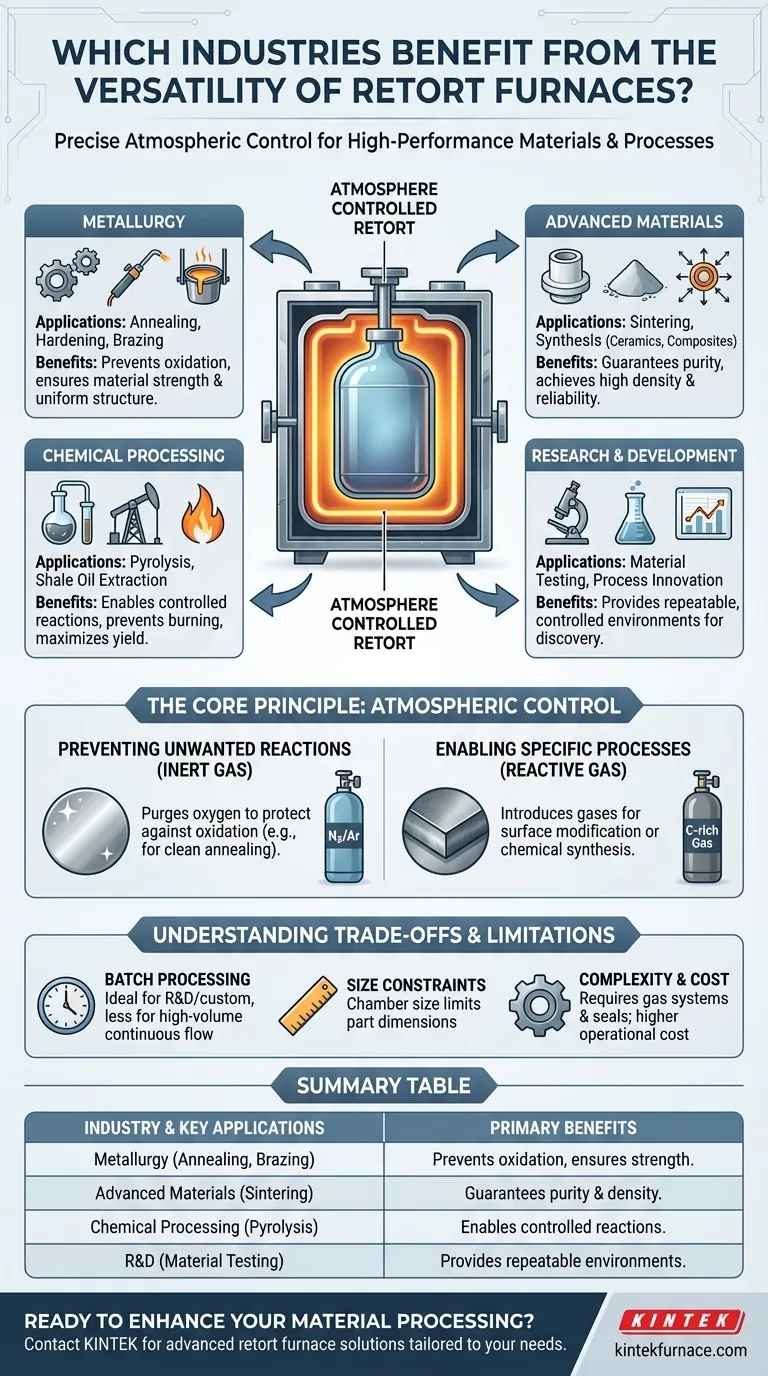

The Core Principle: Why Atmospheric Control is Crucial

A retort furnace is fundamentally a sealed chamber (the "retort") placed inside a heating system. This separation is the key to its function, allowing operators to create a specific, controlled environment around the workpiece, independent of the furnace's heating elements.

Preventing Unwanted Reactions

Many materials, especially metals, react with oxygen at high temperatures. This process, called oxidation, can degrade the material's surface, weaken its structure, and compromise its performance.

By filling the retort with an inert gas like nitrogen or argon, oxygen is purged from the chamber. This protects the material, ensuring processes like annealing or sintering result in a clean, pure, and strong final product.

Enabling Specific Chemical Processes

Conversely, sometimes a reaction is desired. A retort furnace allows for the introduction of reactive gases to intentionally alter a material.

For example, introducing a carbon-rich gas can harden the surface of steel. In chemical processing, heating materials like oil shale in a controlled environment is essential for extracting valuable compounds without them burning away.

Ensuring Material Purity and Uniformity

For high-tech applications like electronics or advanced ceramics, even trace amounts of contamination can lead to component failure.

The sealed retort ensures that no contaminants from the heating elements or outside air can reach the workpiece. This guarantees the purity, consistency, and reliability required for high-performance materials.

Key Applications Across Core Industries

The principle of atmospheric control unlocks critical processes used in some of the most demanding industrial and scientific fields.

Metallurgy: Shaping and Joining Metals

In metallurgy, heat is used to alter a metal's physical properties.

Processes like annealing (softening metal for forming), hardening (strengthening it), and furnace brazing (joining components with a filler metal) all require precise temperature and atmosphere control to prevent oxidation and ensure the desired structural outcome.

Advanced Materials: Sintering and Synthesis

Industries creating ceramics, composite materials, and parts from metal powders rely heavily on retort furnaces.

The process of sintering involves heating powdered material until its particles bond together, forming a dense, solid object. A controlled atmosphere is essential to prevent impurities and achieve the target density and strength, which is critical for everything from ceramic insulators to powder metallurgy components.

Chemical Processing: Driving Reactions with Heat

A retort furnace acts as a self-contained, high-temperature reaction vessel.

It is used in processes like charcoal development and shale oil extraction, where organic matter is heated in an oxygen-deprived environment (pyrolysis) to break it down into desired byproducts. It is also used for studying and executing other high-temperature chemical reactions.

Research & Development: The Foundation of Innovation

For universities and research institutes, the retort furnace is an indispensable laboratory tool. It provides the controlled and repeatable environment necessary to develop and test new materials, study high-temperature phenomena, and pioneer novel manufacturing processes.

Understanding the Trade-offs and Limitations

While highly versatile, retort furnaces are not the universal solution for all heating applications. Understanding their limitations is key to making an informed decision.

Batch Processing vs. Continuous Flow

Retort furnaces are inherently batch-processing tools. You load a batch, run the process, cool it down, and unload it. This is perfect for R&D, custom parts, or moderate production volumes.

For high-volume, standardized manufacturing, a continuous furnace (where parts move through on a conveyor) may be more efficient.

Size and Capacity Constraints

The physical size of the retort chamber limits the dimensions of the parts that can be processed. While very large retort furnaces exist, they are less common and more complex than similarly-sized open-air furnaces.

Complexity and Cost

Maintaining a sealed, controlled atmosphere adds a layer of complexity. It requires gas management systems, robust seals, and safety protocols. This makes retort furnaces generally more expensive to purchase and operate than simple furnaces that heat in ambient air.

Matching the Furnace to Your Objective

Choosing the right thermal processing technology depends entirely on your end goal.

- If your primary focus is material purity and strength: A retort furnace's atmospheric control is non-negotiable for preventing oxidation in critical processes like annealing, brazing, and sintering.

- If your primary focus is enabling specific chemical reactions: The retort furnace's function as a sealed reaction chamber is essential for processes from material synthesis to hydrocarbon extraction.

- If your primary focus is high-volume, low-complexity heat treatment: The batch-based nature of a retort furnace may be a bottleneck; a continuous or simple air furnace could be a more cost-effective choice.

Ultimately, mastering the use of a retort furnace begins with understanding that you are controlling not just temperature, but the very environment in which your materials are transformed.

Summary Table:

| Industry | Key Applications | Benefits of Retort Furnace |

|---|---|---|

| Metallurgy | Annealing, hardening, brazing | Prevents oxidation, ensures material strength |

| Advanced Materials | Sintering, synthesis | Guarantees purity and density for ceramics and composites |

| Chemical Processing | Pyrolysis, shale oil extraction | Enables controlled reactions, prevents burning |

| Research & Development | Material testing, innovation | Provides repeatable, controlled environments for R&D |

Ready to enhance your material processing with precise atmospheric control? KINTEK specializes in advanced high-temperature furnace solutions, including retort furnaces, tailored for industries like metallurgy, ceramics, electronics, and chemical processing. Leveraging our exceptional R&D and in-house manufacturing, we offer products such as Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, with strong deep customization to meet your unique experimental needs. Contact us today to discuss how our solutions can boost your efficiency and innovation!

Visual Guide

Related Products

- 1200℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1400℃ Controlled Inert Nitrogen Atmosphere Furnace

- Mesh Belt Controlled Atmosphere Furnace Inert Nitrogen Atmosphere Furnace

- Controlled Inert Nitrogen Hydrogen Atmosphere Furnace

People Also Ask

- What is nitrogen used for in a furnace? Prevent Oxidation and Control Heat Treatment Quality

- How does the inert atmosphere heat treating process work? Prevent Oxidation for Superior Material Quality

- How does nitrogen atmosphere heat treatment improve surface strengthening? Enhance Durability and Performance

- What are the environmental benefits of using inert gases in furnaces? Reduce Waste and Emissions for a Greener Process

- What does inert mean in furnace atmospheres? Protect materials from oxidation with inert gases.