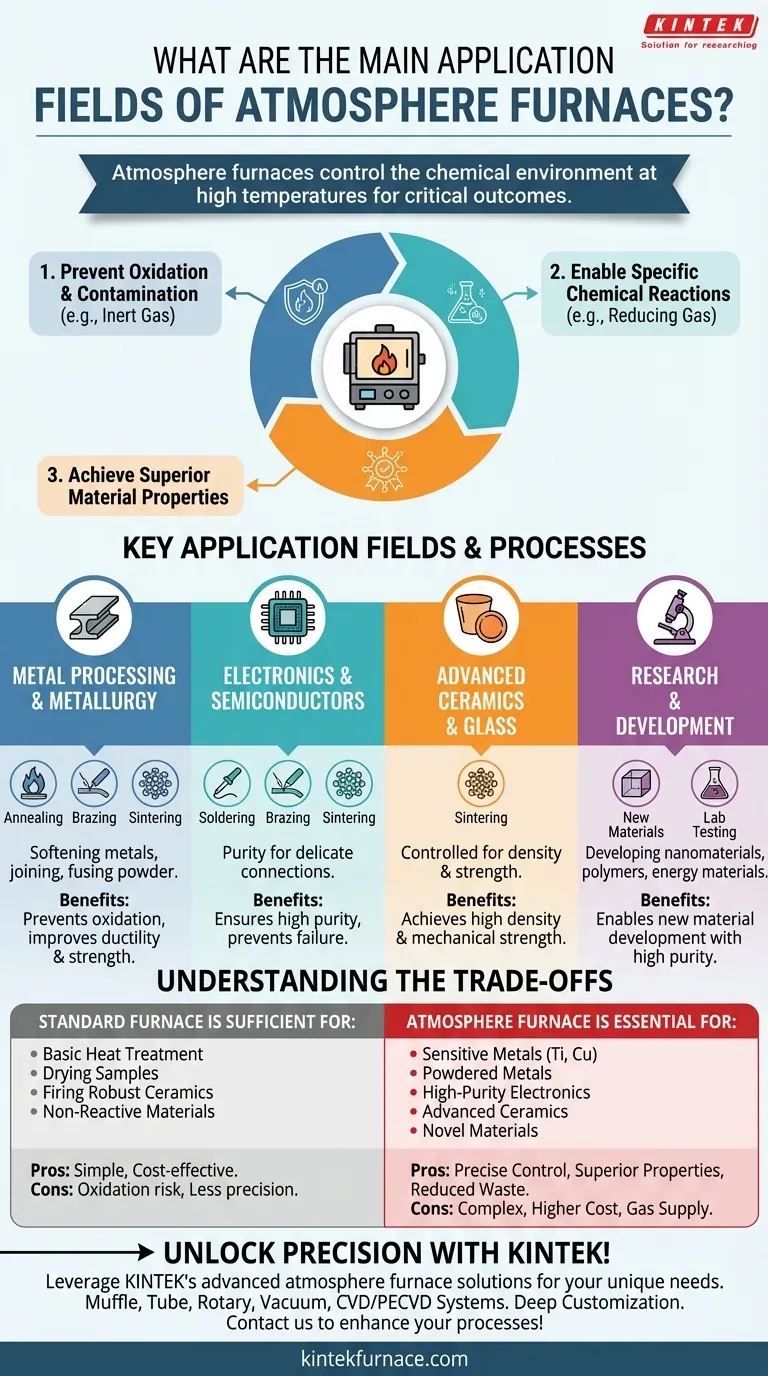

At their core, atmosphere furnaces are specialized tools used in any high-temperature process where controlling the chemical environment is critical to the outcome. Their main application fields include advanced metal processing, semiconductor manufacturing, and the research and development of new materials, where they prevent unwanted reactions like oxidation and ensure the final product meets exacting specifications.

The fundamental difference between a standard furnace and an atmosphere furnace is control. While any furnace provides heat, an atmosphere furnace also provides a precisely managed gaseous environment, protecting sensitive materials from damage and enabling specific chemical transformations that would be impossible in open air.

The Core Principle: Why Control the Atmosphere?

The decision to use an atmosphere furnace stems from a single need: to manage the chemical reactions that occur at high temperatures. Heating materials in ambient air, which is rich in oxygen, can be destructive.

Preventing Oxidation and Contamination

At high temperatures, oxygen aggressively reacts with many materials, a process known as oxidation. For metals, this often results in scaling, embrittlement, or a complete loss of structural integrity.

An atmosphere furnace prevents this by replacing the air with a controlled gas. Using an inert gas like argon or nitrogen creates a neutral environment that protects the material from any chemical change during heating.

Enabling Specific Chemical Reactions

Beyond simple protection, these furnaces can create environments that actively change a material. For example, introducing a reducing environment (like hydrogen) can remove oxides from a material's surface.

This level of control is essential for processes that rely on precise chemical pathways to achieve their goals, such as in the manufacturing of certain electronic components or catalysts.

Achieving Superior Material Properties

Ultimately, atmospheric control is about achieving specific, repeatable material properties. By preventing contamination and guiding chemical reactions, manufacturers can ensure a material has the desired strength, conductivity, purity, or density.

This precision is what makes atmosphere furnaces indispensable in high-stakes industries like aerospace, medical device manufacturing, and electronics.

Key Application Fields and Processes

The need for atmospheric control spans a wide range of industries and sophisticated manufacturing processes.

Metal Processing and Metallurgy

This is a primary field for atmosphere furnaces. Key processes include:

- Annealing: Softening metals to improve their ductility, performed in an inert atmosphere to prevent surface scaling.

- Brazing: Joining metals using a filler material, where a clean, oxide-free surface is critical for a strong bond.

- Sintering: Fusing metal powders together below their melting point. This is fundamental to powder metallurgy and is used to create complex parts from materials like titanium alloys.

Electronics and Semiconductor Manufacturing

The purity required for electronic components makes atmospheric control non-negotiable. The furnaces are used for soldering and brazing delicate connections without oxidation.

They are also critical for sintering ceramic substrates and other components in devices where even microscopic impurities can cause a failure.

Advanced Ceramics and Glass Production

For advanced technical ceramics, the sintering process must be perfectly controlled to achieve the desired density and mechanical strength.

An atmosphere furnace ensures that no unwanted gas pockets or chemical impurities are trapped within the material, which would otherwise create weak points.

Research and Development

In materials science, atmosphere furnaces are essential laboratory tools for creating and testing new materials. Researchers rely on them to develop nanomaterials, polymer materials, and new energy materials like those used in solar cells, where environmental purity is paramount.

Understanding the Trade-offs

Choosing an atmosphere furnace involves weighing its powerful capabilities against its increased complexity and cost compared to conventional furnaces.

When a Standard Furnace is Sufficient

For many basic applications, a conventional box furnace is the right tool. Processes like drying samples, heat-treating non-sensitive metals, or firing robust ceramics do not require the expense and complexity of atmospheric control.

If the material is not reactive with oxygen at the target temperature, a standard furnace is often the most practical and cost-effective choice.

The Cost and Complexity of Control

Operating an atmosphere furnace requires more than just heat. It demands a reliable supply of high-purity gas, precise systems for monitoring and maintaining pressure and flow, and strict safety protocols, especially when using flammable gases like hydrogen.

This adds layers of operational complexity, maintenance requirements, and initial investment compared to a simple furnace.

The Clear Benefit of Precision

Despite the added complexity, the benefits are undeniable for the right application. By preventing material loss from oxidation, atmosphere furnaces can reduce waste and lower costs.

More importantly, they enable the creation of higher-quality products with superior and more consistent properties, which is a fundamental requirement in nearly all high-technology fields.

Making the Right Choice for Your Process

Your choice must be driven by the specific demands of your material and the properties you need to achieve.

- If your primary focus is basic heat treatment or firing robust, non-sensitive materials: A conventional furnace is the most direct and cost-effective solution.

- If you are working with oxidation-sensitive metals like titanium, copper alloys, or creating powdered metal parts: An atmosphere furnace is essential to preserve material integrity.

- If you are manufacturing high-purity electronics, advanced ceramics, or developing novel materials: The precise environmental control of an atmosphere furnace is non-negotiable for achieving the required performance.

Ultimately, selecting the right furnace depends on whether atmospheric control is a helpful option or a fundamental requirement for your material's success.

Summary Table:

| Application Field | Key Processes | Benefits |

|---|---|---|

| Metal Processing | Annealing, Brazing, Sintering | Prevents oxidation, improves ductility and strength |

| Electronics & Semiconductors | Soldering, Brazing, Sintering | Ensures high purity, prevents component failure |

| Advanced Ceramics & Glass | Sintering | Achieves density and mechanical strength |

| Research & Development | Material synthesis and testing | Enables development of new materials with high purity |

Unlock precision in your high-temperature processes with KINTEK! Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with advanced atmosphere furnace solutions, including Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures we meet your unique experimental needs, delivering superior material properties and reduced waste. Contact us today to discuss how our furnaces can enhance your metal processing, electronics manufacturing, or materials research!

Visual Guide

Related Products

- 1200℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1400℃ Controlled Inert Nitrogen Atmosphere Furnace

- Mesh Belt Controlled Atmosphere Furnace Inert Nitrogen Atmosphere Furnace

- Controlled Inert Nitrogen Hydrogen Atmosphere Furnace

People Also Ask

- What are the key advantages of an experimental box type atmosphere furnace? Achieve Precise Environmental Control for Advanced Materials

- How does a batch type controlled atmosphere furnace operate? Master Precision Heat Treatment for Superior Materials

- What are the benefits of inert atmosphere heat treating? Prevent Oxidation and Preserve Material Integrity

- What are the applications of inert atmosphere furnaces? Essential for Metal Processing, Electronics, and Additive Manufacturing

- What is nitrogen used for in a furnace? Prevent Oxidation and Control Heat Treatment Quality