In material science and industrial processing, an atmosphere box furnace is a specialized high-temperature oven that enables precise control over the chemical environment surrounding a material. Unlike a standard furnace that operates in ambient air, it allows users to introduce specific gases—such as inert argon or nitrogen, or reducing hydrogen—to prevent unwanted reactions like oxidation and to actively drive the formation of new materials with specific, desirable properties.

The true value of an atmosphere box furnace is not just its ability to heat materials, but its power to control the chemical reactions that occur at high temperatures. This transforms the furnace from a simple oven into a precision instrument for creating and refining advanced materials.

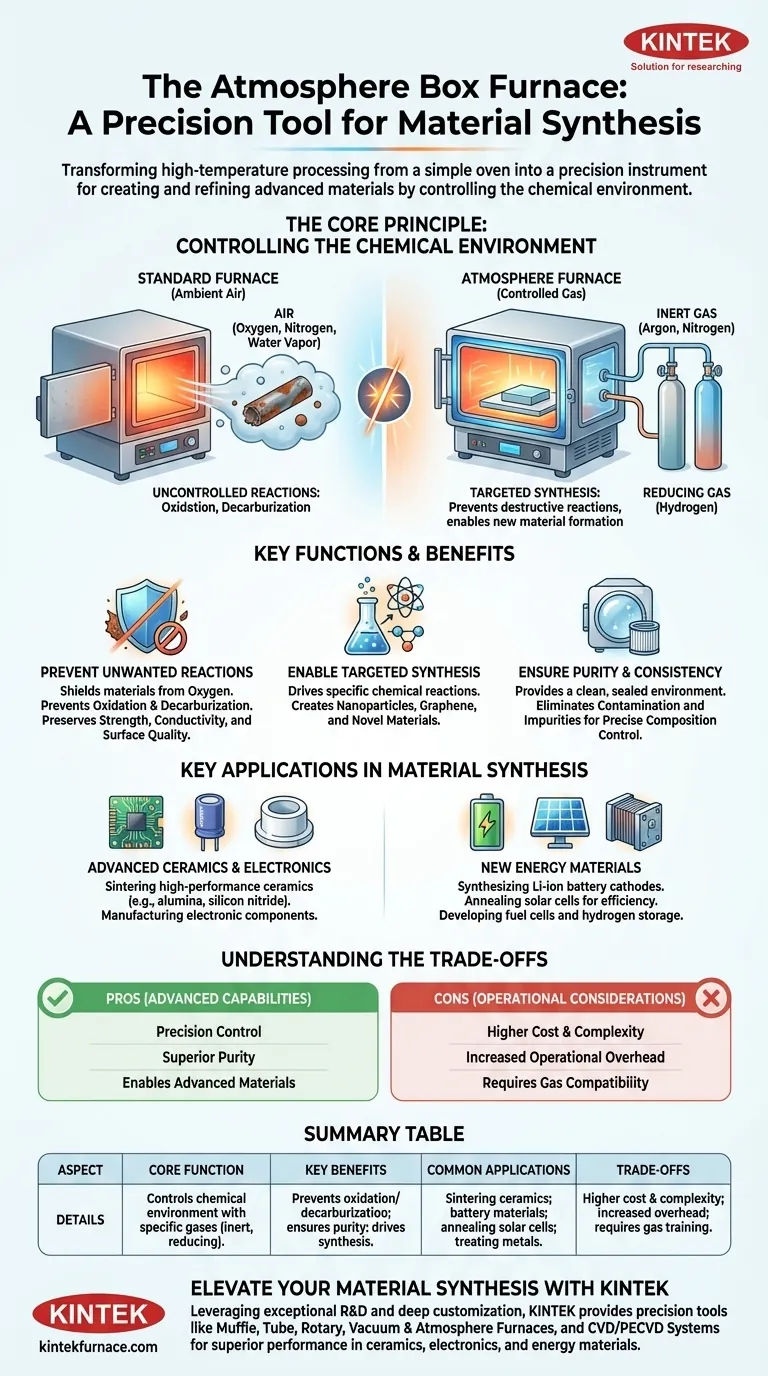

The Core Principle: Controlling the Chemical Environment

The fundamental advantage of an atmosphere furnace is its ability to create a tightly controlled, sealed environment. This control is the key to preventing destructive reactions and enabling targeted material synthesis.

Preventing Unwanted Reactions

Many materials, especially metals, react with oxygen in the air at high temperatures, a process called oxidation (e.g., rust). This can degrade a material's strength, conductivity, and surface finish.

Similarly, high-carbon steels can lose carbon to the surrounding atmosphere in a process called decarburization, making them weaker. An atmosphere furnace prevents these issues by replacing the air with a non-reactive (inert) gas.

Enabling Targeted Synthesis

Specific atmospheres can be used to drive desired chemical reactions. For example, heating metal oxides in an inert atmosphere can produce pure metal nanoparticles.

Likewise, heating carbon-containing materials in a reducing atmosphere (which removes oxygen) is a key step in producing advanced carbon materials like graphene.

Ensuring Purity and Consistency

By creating a vacuum or flooding the chamber with a high-purity gas, the furnace provides a clean, contamination-free environment. This eliminates impurities and unwanted side reactions, giving researchers and manufacturers precise control over the final material's composition and structure.

Key Applications in Material Synthesis

This level of control makes the atmosphere furnace indispensable for creating a wide range of advanced materials that are impossible to produce in a standard air furnace.

Advanced Ceramics and Electronics

The furnace is essential for the preparation and sintering of high-performance ceramics. By carefully managing temperature and atmosphere, it can produce dense, strong products like alumina ceramics or specialized materials like silicon nitride.

This process is also critical for manufacturing electronic components, such as multilayer ceramic capacitors, which require flawless, pure material layers.

New Energy Materials

Atmosphere furnaces play a vital role in synthesizing next-generation energy materials. They facilitate the high-temperature solid-state reactions needed to create lithium-ion battery cathode materials with superior electrochemical performance.

For solar cells, they are used for doping and annealing silicon wafers to improve photoelectric conversion efficiency. They also support the development of fuel cell electrolytes and hydrogen storage materials.

Understanding the Trade-offs

While powerful, atmosphere furnaces are not a universal solution. Their specialized nature comes with clear trade-offs compared to conventional air furnaces.

Increased Cost and Complexity

The systems required for creating a vacuum, ensuring a perfect seal, and managing gas flow make these furnaces significantly more complex and expensive to purchase and maintain.

Higher Operational Overhead

Each process cycle requires additional steps, such as purging the chamber of air and backfilling it with the desired gas. This adds time, requires a consistent supply of high-purity gases, and demands more operator training to ensure safety and effectiveness.

Material and Atmosphere Compatibility

The choice of atmosphere is a critical parameter. Some materials may react negatively with certain gases, even those considered inert at lower temperatures. The furnace's internal components must also be compatible with the process gases and high temperatures, limiting some potential applications.

Making the Right Choice for Your Goal

Selecting the right thermal processing method depends entirely on the required outcome for your material.

- If your primary focus is synthesizing novel materials: An atmosphere furnace is essential for creating specific, pure structures like nanoparticles, graphene, or battery cathodes where environmental control is non-negotiable.

- If your primary focus is producing high-performance ceramics or electronics: This furnace is critical for achieving dense, pure materials with the specific structural and electrical properties required for these demanding applications.

- If your primary focus is treating metals and alloys: The furnace's ability to prevent oxidation and decarburization is the key to preserving or enhancing mechanical properties like strength, ductility, and surface quality.

Ultimately, the atmosphere box furnace transforms high-temperature processing from a blunt instrument into a precision tool for material innovation.

Summary Table:

| Aspect | Details |

|---|---|

| Core Function | Controls chemical environment with specific gases (e.g., inert, reducing) to prevent unwanted reactions and enable targeted synthesis. |

| Key Benefits | Prevents oxidation and decarburization; ensures purity and consistency; drives reactions for advanced materials. |

| Common Applications | Sintering ceramics; synthesizing battery materials; annealing solar cells; treating metals and alloys. |

| Trade-offs | Higher cost and complexity; increased operational overhead; requires gas compatibility and operator training. |

Elevate your material synthesis with KINTEK's advanced high-temperature furnace solutions! Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with precision tools like Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures we meet your unique experimental needs, delivering superior performance in ceramics, electronics, and energy materials. Contact us today to discuss how we can enhance your research and production processes!

Visual Guide

Related Products

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1200℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1400℃ Controlled Inert Nitrogen Atmosphere Furnace

- Controlled Inert Nitrogen Hydrogen Atmosphere Furnace

- Laboratory Muffle Oven Furnace with Bottom Lifting

People Also Ask

- How does a mixed gas flow control system maintain stability during high-temperature nitriding? Precision Gas Ratios

- What are the development prospects of atmosphere box furnaces in the aerospace industry? Unlock Advanced Material Processing for Aerospace Innovation

- How do argon and nitrogen protect samples in vacuum furnaces? Optimize Your Thermal Process with the Right Gas

- What are some specific applications of atmosphere furnaces in the ceramics industry? Enhance Purity and Performance

- What are the primary inert gases used in vacuum furnaces? Optimize Your Heat Treatment Process