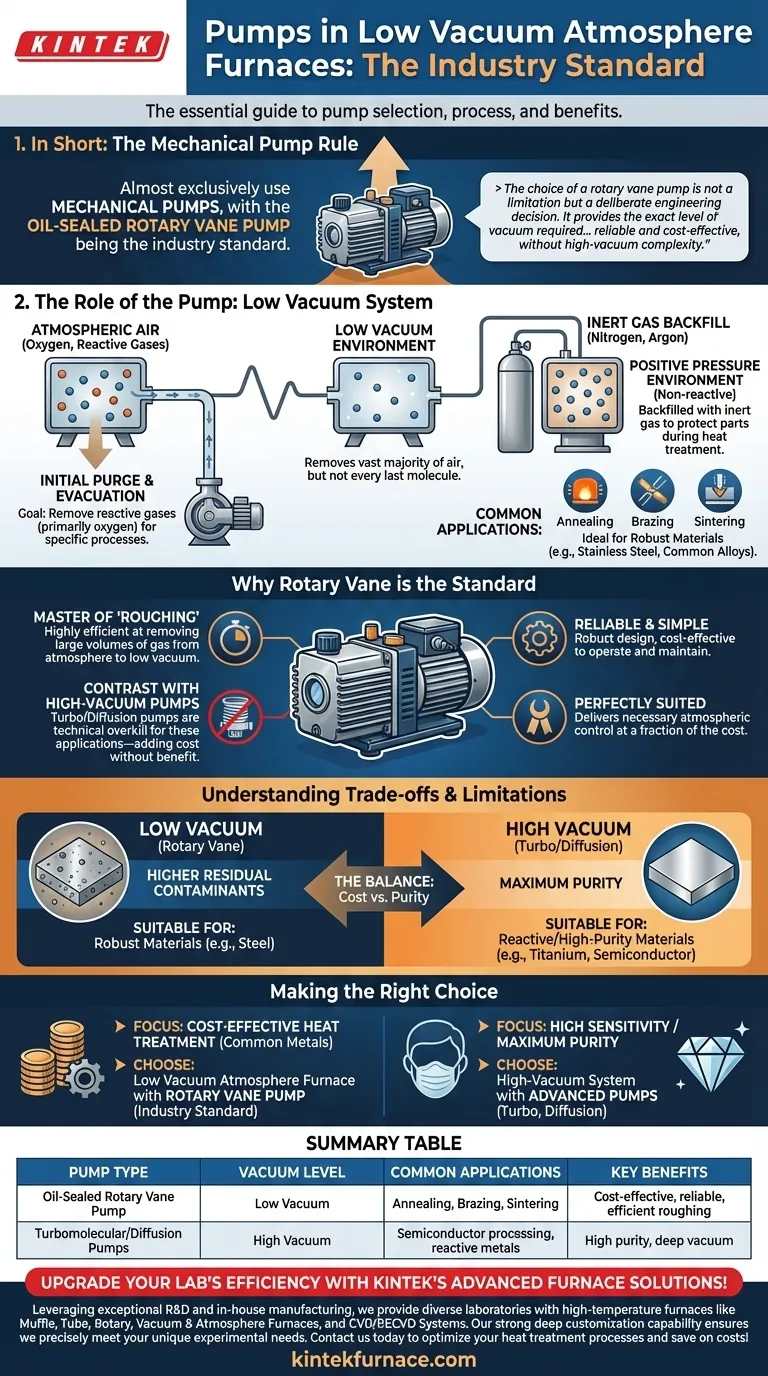

In short, low vacuum atmosphere furnaces almost exclusively use mechanical pumps, with the oil-sealed rotary vane pump being the industry standard. These pumps are designed to quickly remove the bulk of atmospheric air before the furnace is backfilled with an inert gas like nitrogen or argon, creating the required processing environment.

The choice of a rotary vane pump is not a limitation but a deliberate engineering decision. It provides the exact level of vacuum required for these applications in a reliable and cost-effective manner, without the complexity and expense of high-vacuum systems.

The Role of the Pump in a Low Vacuum System

A low vacuum atmosphere furnace isn't designed to create the void of outer space. Its goal is to remove reactive gases—primarily oxygen—so a specific industrial process can occur without unwanted chemical reactions like oxidation.

Defining the "Low Vacuum" Environment

The term "low vacuum" signifies that the system removes the vast majority of air but does not attempt to eliminate every last molecule. The primary goal is to create a sufficiently clean slate before introducing a controlled atmosphere.

The Inert Gas Backfill is Key

After the mechanical pump evacuates the chamber, the furnace is backfilled with a high-purity inert gas, such as nitrogen or argon. This gas creates a positive pressure environment that is non-reactive, protecting the parts inside during heat treatment. The pump's job is simply the initial purge.

Common Applications Drive the Requirements

These furnaces are workhorses for processes where absolute purity is not the primary concern. Common uses include annealing, brazing, and sintering of materials that are less sensitive to trace amounts of oxygen, such as stainless steel and other common alloys.

Why the Rotary Vane Pump is the Standard

Different pumps are designed for different vacuum levels. For low vacuum furnaces, the robust and efficient rotary vane pump is perfectly suited for the task.

The Workhorse of Roughing Vacuums

Rotary vane pumps are masters of "roughing," which means they are highly efficient at removing large volumes of gas from atmospheric pressure down to the low vacuum range. They are reliable, relatively simple, and cost-effective to operate and maintain.

Contrast with High-Vacuum Pumps

Pumps like turbomolecular or diffusion pumps are designed to achieve much deeper vacuums. Using them on a low vacuum atmosphere furnace would be technical overkill—adding significant cost and complexity for no practical benefit to the process.

Understanding the Trade-offs and Limitations

The decision to use a low vacuum system and its associated pump is a conscious trade-off between process requirements, material sensitivity, and cost.

Inevitable Risk of Contamination

Compared to high-vacuum systems, low vacuum furnaces inherently have a higher level of residual atmospheric contaminants. This makes them unsuitable for processing highly reactive or high-purity materials.

Direct Impact on Material Suitability

This trade-off dictates what you can safely process. A low vacuum is perfectly adequate for robust materials like steel, but it is entirely inappropriate for reactive metals like titanium or materials used in semiconductor manufacturing, which demand high-vacuum purity.

The Balance of Cost vs. Purity

Ultimately, a low vacuum furnace equipped with a rotary vane pump represents a strategic balance. It delivers the necessary atmospheric control for a wide range of common industrial applications at a fraction of the cost and complexity of a high-vacuum system.

Making the Right Choice for Your Goal

Selecting the correct vacuum system is about aligning the equipment's capability with the material's sensitivity and the desired outcome.

- If your primary focus is cost-effective heat treatment of common metals like steel: A low vacuum atmosphere furnace with a rotary vane pump is the industry-standard and most logical choice.

- If your primary focus is processing highly sensitive materials or achieving maximum purity: You must invest in a high-vacuum system that utilizes more advanced pumps, like turbomolecular or diffusion pumps.

Choosing the right pump is about precisely matching the technology to your material's needs and your operational goals.

Summary Table:

| Pump Type | Vacuum Level | Common Applications | Key Benefits |

|---|---|---|---|

| Oil-Sealed Rotary Vane Pump | Low Vacuum | Annealing, Brazing, Sintering | Cost-effective, reliable, efficient roughing |

| Turbomolecular/Diffusion Pumps | High Vacuum | Semiconductor processing, reactive metals | High purity, deep vacuum |

Upgrade your lab's efficiency with KINTEK's advanced furnace solutions! Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with high-temperature furnaces like Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures we precisely meet your unique experimental needs. Contact us today to discuss how our reliable pumps and furnaces can optimize your heat treatment processes and save on costs!

Visual Guide

Related Products

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

- Laboratory Vacuum Tilt Rotary Tube Furnace Rotating Tube Furnace

- Ultra Vacuum Electrode Feedthrough Connector Flange Power Lead for High Precision Applications

- CF KF Flange Vacuum Electrode Feedthrough Lead Sealing Assembly for Vacuum Systems

- High Performance Vacuum Bellows for Efficient Connection and Stable Vacuum in Systems

People Also Ask

- What are some applications of rotary tube furnaces? Ideal for Continuous High-Temperature Material Processing

- What are the benefits of continuous sample movement in rotary tube furnaces? Boost Uniformity and Efficiency

- What are the key features of a rotary furnace? Achieve Superior Uniformity and Control

- What are the main advantages of rotary tube furnaces? Achieve Superior Uniformity and Efficiency in Thermal Processing

- How is the structure of a rotary tube furnace characterized? Discover Its Key Components and Benefits