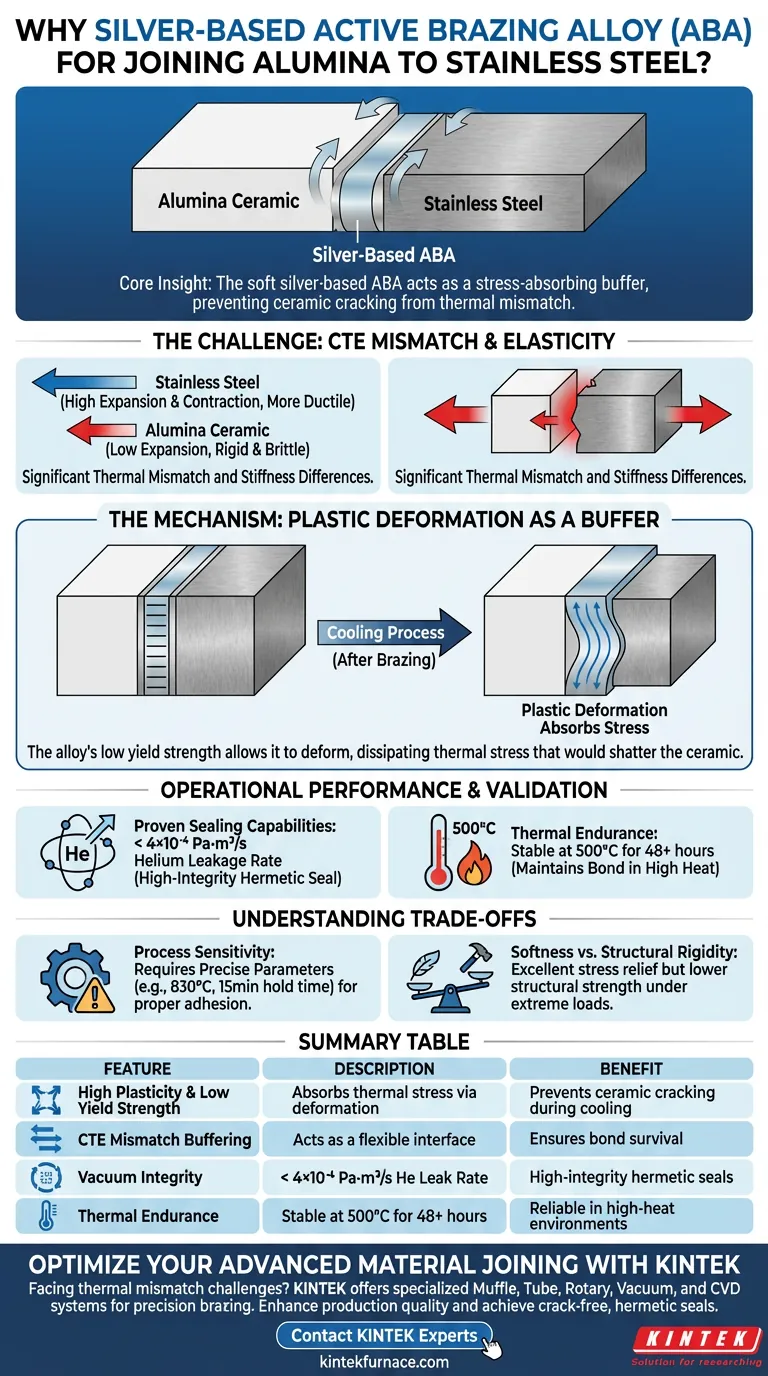

Silver-based Active Brazing Alloy (ABA) is chosen primarily for its exceptional plasticity and low yield strength. When joining alumina ceramics to stainless steel, the interface faces significant mechanical tension due to the disparate physical properties of the materials. The soft nature of silver-based ABA allows it to physically deform during the cooling process, absorbing this stress and preventing the brittle ceramic component from cracking.

The Core Insight The fundamental challenge in joining ceramics to metals is managing thermal mismatch. Silver-based ABA acts as a stress-absorbing buffer; its ability to undergo plastic deformation alleviates residual forces that would otherwise shatter the ceramic interface.

The Challenge of Dissimilar Materials

Coefficient of Thermal Expansion (CTE) Mismatch

The primary driver for using silver-based ABA is the significant difference in how the two materials react to heat.

Stainless steel expands and contracts significantly as temperatures change. Alumina ceramic, by contrast, is much more dimensionally stable. During the cooling phase of brazing, the steel contracts faster than the ceramic, creating immense pulling forces at the joint.

Elastic Modulus Differences

The materials also differ in their stiffness, known as the elastic modulus.

Alumina ceramic is extremely rigid and brittle; it does not stretch. Austenitic stainless steel is more ductile but still strong. Without a flexible interface, the rigid ceramic bears the brunt of the contraction forces, leading to inevitable fracture.

The Mechanism of Silver-Based ABA

Plastic Deformation as a Buffer

Silver-based ABA solves the mismatch problem through its low yield strength.

Because the alloy is physically soft, it yields (stretches or compresses) easily under stress. Instead of transferring the thermal contraction force directly to the ceramic, the braze layer itself deforms. This "sacrifice" by the alloy dissipates the energy that would otherwise cause failure.

Alleviating Residual Stress

The critical moment occurs during the cooling process after brazing.

As the joint cools, the alloy undergoes plastic deformation to accommodate the shrinking steel. This effectively "relaxes" the joint, significantly reducing the thermal residual stress accumulated at the interface.

Operational Performance and Validation

Proven Sealing Capabilities

The effectiveness of this material choice is validated by its ability to maintain a hermetic seal.

Using specific alloys like AgCu28Ni1.5, joints demonstrate a helium leakage rate of less than 4×10⁻⁴ Pa·m³/s. This indicates a high-integrity bond suitable for vacuum applications.

Thermal Endurance

Despite its softness, the alloy maintains integrity at elevated operational temperatures.

Tests confirm that these joints can withstand 500°C for extended periods (48 hours) without failing. This proves that the plasticity of the silver base does not compromise its ability to function in high-heat environments.

Understanding the Trade-offs

Process Sensitivity

While silver-based ABA is effective, the process requires precise control to achieve the correct mechanical properties.

For example, specific protocols—such as a brazing temperature of 830°C and a hold time of 15 minutes—are necessary to ensure the alloy wets the surface properly without degrading. Deviating from these parameters can result in a joint that is either too brittle or lacks proper adhesion.

Softness vs. Structural Rigidity

The very trait that makes silver-based ABA desirable—its softness—is also a structural constraint.

Because the alloy has low yield strength, it is excellent for relieving thermal stress but may not be suitable for joints that must bear extreme mechanical loads or shear forces. The design relies on the ceramic and steel for structural strength, while the braze acts strictly as the connective tissue.

Making the Right Choice for Your Goal

When designing joints between alumina and stainless steel, consider your primary performance metrics.

- If your primary focus is Crack Prevention: Prioritize silver-based ABA, as its high plasticity is the most effective defense against the CTE mismatch that shatters ceramics.

- If your primary focus is Hermetic Sealing: Ensure your process adheres to strict parameters (like the 830°C/15min cycle) to achieve low helium leakage rates.

Ultimately, silver-based ABA is the industry standard for this application because it prioritizes the survival of the ceramic component over the rigidity of the bond.

Summary Table:

| Feature | Description | Benefit |

|---|---|---|

| Material Property | High Plasticity & Low Yield Strength | Absorbs thermal stress through deformation |

| Thermal Management | CTE Mismatch Buffering | Prevents ceramic cracking during cooling |

| Vacuum Integrity | < 4×10⁻⁴ Pa·m³/s Helium Leak Rate | Ensures high-integrity hermetic seals |

| Thermal Endurance | Stable at 500°C for 48+ hours | Maintains bond integrity in high-heat environments |

Optimize Your Advanced Material Joining with KINTEK

Facing challenges with thermal expansion mismatch or ceramic-to-metal bonding? KINTEK provides the specialized equipment and expertise needed for precision brazing. Backed by expert R&D and manufacturing, we offer high-performance Muffle, Tube, Rotary, Vacuum, and CVD systems, all fully customizable for your unique laboratory or industrial needs.

Enhance your production quality and achieve crack-free, hermetic seals today.

Visual Guide

References

- Jian Feng, Antonio Hurtado. Active Brazing for Energy Devices Sealing. DOI: 10.3390/jeta2010001

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Vacuum Heat Treat Sintering and Brazing Furnace

- 1200℃ Split Tube Furnace Laboratory Quartz Tube Furnace with Quartz Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- Laboratory Muffle Oven Furnace with Bottom Lifting

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

People Also Ask

- Why is a vacuum drying oven essential for the processing of battery electrode sheets? Ensure Battery Safety & Longevity

- What advantages does a vacuum drying oven offer over a standard oven for Fe3Al and CNTs? Protect Your Composites

- What are the two common hot zone configurations in vertical vacuum furnaces? Compare Graphite vs. All-Metal

- What factors must be controlled during furnace brazing to ensure a reliable joint? Master the 5 Key Variables for Strong Bonds

- Why is a vacuum annealing furnace necessary for PBF-LB/M titanium alloys? Optimize Material Integrity

- What heating elements are used in laboratory vacuum furnaces and their temperature ranges? Optimize Your High-Temp Processes

- How does a vacuum heat treatment furnace prevent contamination? Ensure Purity in High-Temperature Processes

- How is a vacuum furnace energy-efficient? Uncover Key Mechanisms for Lower Costs