High-precision gas atomization is the prerequisite for successfully fabricating skeleton-reinforced nanoporous copper because it is the only reliable method to produce alloy powders with the necessary physical uniformity. This equipment specifically generates powders with high sphericity, precise chemical compositions, and a targeted particle size distribution (D50 ≈ 42.7 μm). These attributes are critical for ensuring the raw material behaves consistently during the sensitive laser powder bed fusion process.

The success of the final nanoporous structure is determined before printing begins. High-precision atomization ensures flowability and layer uniformity, which are the non-negotiable foundations for minimizing defects and achieving structural integrity.

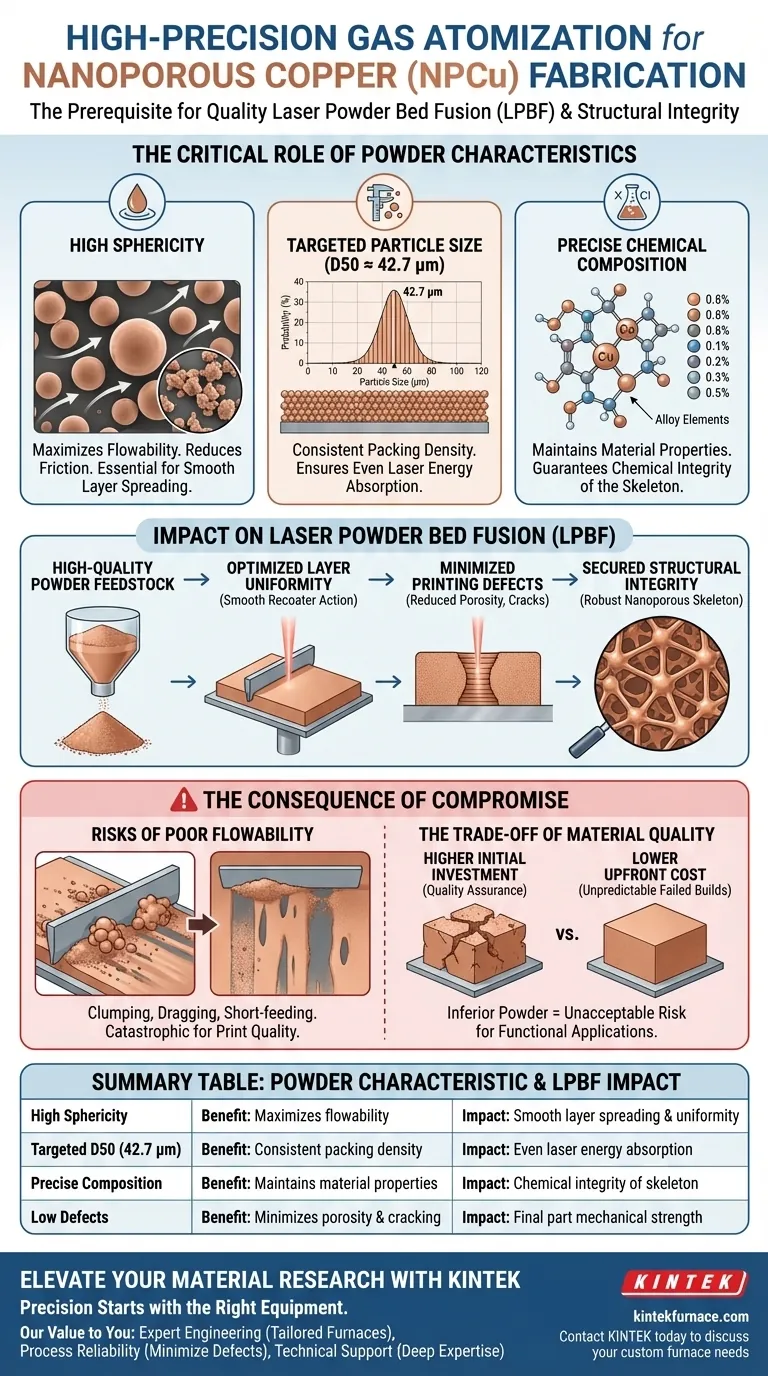

The Critical Role of Powder Characteristics

Achieving High Sphericity

Gas atomization equipment is essential for producing particles that are highly spherical rather than irregular.

Spherical particles encounter less friction against one another, which is the primary factor driving powder flowability. Without this spherical shape, the powder cannot spread smoothly across the build plate.

Controlling Particle Size Distribution

The equipment allows for tight control over particle size, achieving a specific median diameter (D50) of approximately 42.7 μm.

A uniform particle size distribution is vital for consistent packing density. This uniformity ensures that when the laser melts the powder, the energy is absorbed evenly across the bed.

Ensuring Precise Chemical Composition

High-precision equipment guarantees that the alloy powder maintains the exact chemical makeup intended for the final product.

In the context of nanoporous copper, deviations in alloy composition can drastically alter the material's final properties or its reaction to the laser.

Impact on Laser Powder Bed Fusion (LPBF)

Optimizing Layer Uniformity

The flowability provided by spherical particles directly results in uniform layer deposition.

During the LPBF process, a recoater blade spreads fresh powder over the previous layer. If the powder flows well, this new layer will be perfectly flat and consistent, preventing uneven melting.

Minimizing Printing Defects

By ensuring uniform layers and consistent particle sizes, high-precision atomization drastically reduces the occurrence of printing defects.

Irregular powders or uneven layers often lead to porosity, lack of fusion, or cracks within the printed object. Eliminating these variables at the source is the most effective way to ensure quality.

Securing Structural Integrity

The ultimate goal of using this equipment is to protect the structural integrity of the skeleton-reinforced nanoporous copper.

Defects introduced during printing compromise the mechanical strength of the final part. High-quality powder ensures the "skeleton" of the structure is sound and robust.

The Consequence of Compromise

Risks of Poor Flowability

If lower-precision atomization is used, particles may be irregular or "satellite" laden, leading to clumping.

This poor flowability causes the recoater mechanism to drag powder rather than spread it. This results in short-feeding or streaks in the powder bed, which are catastrophic for the print.

The Trade-off of Material Quality

While high-precision equipment represents a higher initial investment or processing cost, it eliminates the hidden costs of failed builds.

Using inferior powder introduces unpredictability. You trade the assurance of structural integrity for lower upfront material costs, a risk that is often unacceptable for functional nanoporous applications.

Making the Right Choice for Your Goal

To ensure the success of your nanoporous copper fabrication, align your material selection with your specific manufacturing objectives.

- If your primary focus is Process Stability: Prioritize powders with high sphericity to maximize flowability and ensure the recoater mechanism operates without interruption.

- If your primary focus is Part Performance: Prioritize precise chemical composition and uniform particle size (D50 ≈ 42.7 μm) to minimize internal defects and guarantee the structural strength of the copper skeleton.

Superior fabrication results are not accidental; they are the direct result of starting with a precise, high-quality powder feedstock.

Summary Table:

| Powder Characteristic | Benefit for NPCu Fabrication | Impact on LPBF Process |

|---|---|---|

| High Sphericity | Maximizes powder flowability | Ensures smooth layer spreading & uniformity |

| Targeted D50 (42.7 μm) | Consistent packing density | Enables even laser energy absorption |

| Precise Composition | Maintains material properties | Guarantees chemical integrity of the skeleton |

| Low Defects | Minimizes porosity & cracking | Secures final part mechanical strength |

Elevate Your Material Research with KINTEK

Precision starts with the right equipment. KINTEK provides industry-leading R&D and manufacturing solutions designed to meet the rigorous demands of advanced material fabrication. Whether you are developing nanoporous copper or complex alloys, our customizable systems—including Muffle, Tube, Rotary, Vacuum, and CVD systems—ensure the thermal precision and atmosphere control your process requires.

Our value to you:

- Expert Engineering: High-temp furnaces tailored to your unique research specifications.

- Process Reliability: Minimize defects and maximize repeatability in your powder bed fusion workflows.

- Technical Support: Backed by deep expertise in lab-scale and industrial manufacturing.

Contact KINTEK today to discuss your custom furnace needs

Visual Guide

References

- Haozhang Zhong, Ma Qian. Skeletal High‐Strength Nanoporous Copper and Metamaterials: The Hakka Tulou Design Heritage. DOI: 10.1002/adma.202503701

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- Electric Rotary Kiln Pyrolysis Furnace Plant Machine Small Rotary Kiln Calciner

- Vacuum Heat Treat Sintering and Brazing Furnace

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

- Vacuum Hot Press Furnace Machine Heated Vacuum Press

People Also Ask

- What are the applications of induction heating? Unlock Precision, Speed & Purity in Your Process

- What is the function of a vacuum arc furnace in the preparation of high-entropy alloy ingots? Achieve Perfect Homogeneity

- What is the primary function of a vacuum arc furnace in the production of Ti-6Al-7Nb alloys? Ensure Peak Material Purity

- Why is a Vacuum Induction Melting (VIM) furnace essential? Secure Superalloy Purity and Performance

- Does induction heating work on graphite? Unlock Rapid, High-Temperature Processing

- What are the efficiency benefits of parallel-connected induction coils? Boost Energy Utilization by Over 20%

- How does an induction furnace function? Discover Efficient, Clean Metal Melting Solutions

- What is the primary purpose of preheating charge materials for C95800 aluminum bronze? Eliminate Porosity Defects