At its core, induction heating is used for a wide range of industrial processes including metal heat treatment, surface hardening, melting, brazing, and welding. Its applications extend into specialized fields like semiconductor manufacturing for crystal growth, sealing containers, and even advanced materials processing.

Induction heating's value comes from its unique ability to generate rapid, precise, and controllable heat directly within an electrically conductive material without any physical contact. This fundamental principle makes it an indispensable tool for applications demanding speed, accuracy, and purity.

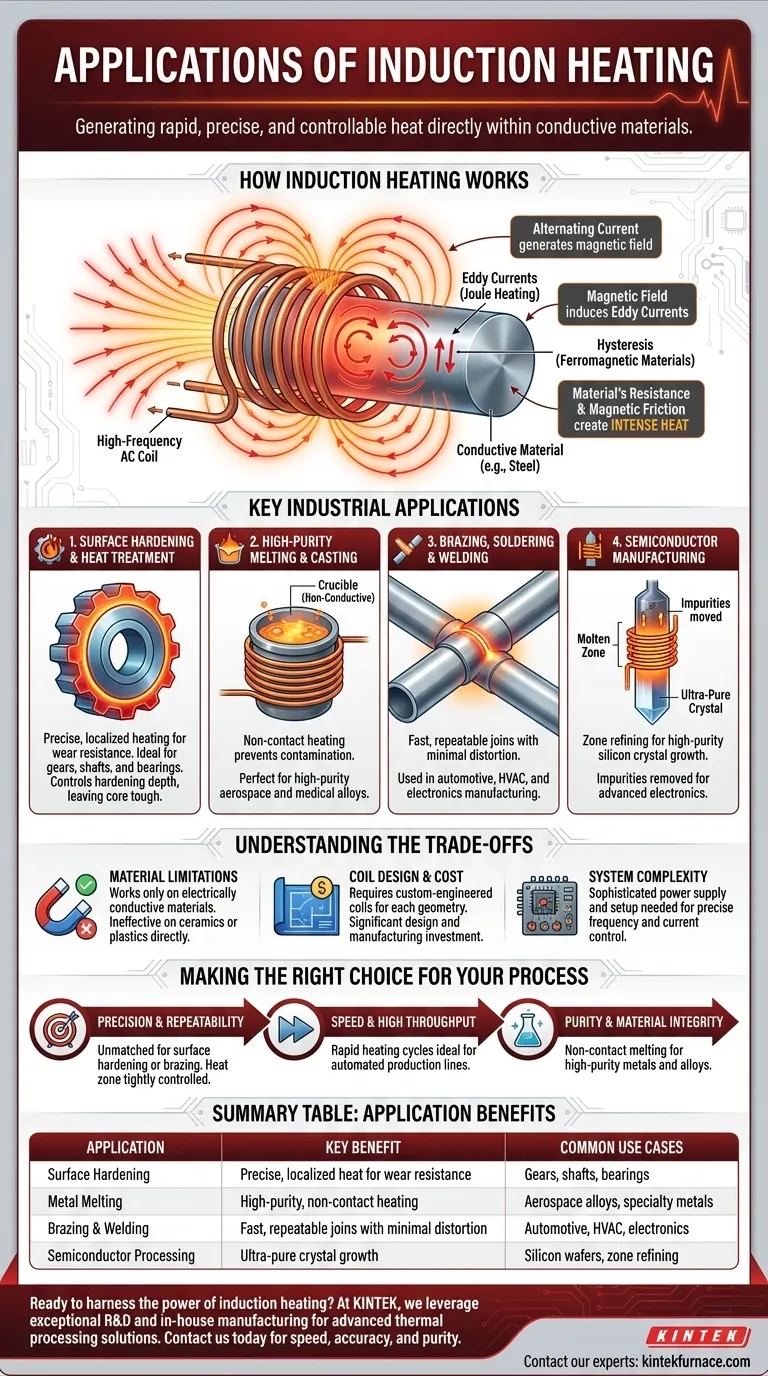

How Induction Heating Works

The Core Principle: Electromagnetic Induction

Induction heating operates on Faraday's Law of electromagnetic induction. A high-frequency alternating current (AC) is passed through a specially designed copper coil.

This current generates a rapidly changing and intense magnetic field around the coil.

Generating Heat from Within

When an electrically conductive part (like a piece of steel) is placed inside this magnetic field, the field induces circular electrical currents within the metal. These are called eddy currents.

The material's natural resistance to the flow of these eddy currents generates immense friction and, therefore, intense heat. This process is known as Joule heating. The heat is generated inside the part itself, not applied from an external source.

The Role of Hysteresis

For ferromagnetic materials like iron, an additional heating effect occurs. The rapidly changing magnetic field causes the material's magnetic domains to flip back and forth, creating internal friction and supplemental heat. This is known as hysteresis loss.

Key Industrial Applications in Detail

Heat Treatment and Surface Hardening

Induction is ideal for hardening the surface of parts like gears, shafts, and bearings while leaving the core ductile and tough.

Because heating is extremely localized to the area within the coil and occurs very quickly, you can precisely control the depth of hardening. This creates a wear-resistant surface without making the entire component brittle.

High-Purity Melting and Casting

Induction furnaces are widely used in metallurgy to melt metals and alloys. Since the heat is generated within the metal itself, there is no contact with a heating element.

This non-contact process prevents contamination, making it perfect for producing high-purity specialty metals and superalloys used in aerospace and medical applications.

Brazing, Soldering, and Welding

The speed and precision of induction heating make it highly effective for joining metals. The heat can be localized to the exact joint area, creating a strong bond quickly without distorting or damaging the surrounding components.

This process is highly repeatable, making it a cornerstone of automated, high-volume manufacturing lines.

Semiconductor Manufacturing

In the production of semiconductors, induction is used for growing high-purity single crystals of silicon.

The process, known as zone refining, uses a narrow induction coil to create a small molten zone that is passed along a material rod. Impurities are drawn into the molten zone and moved to the end of the rod, leaving behind an ultra-pure crystal.

Understanding the Trade-offs

Material Limitations

Induction heating's primary limitation is that it only works on electrically conductive materials. It is ineffective for heating non-conductive materials like most ceramics or plastics directly, though it can be used to heat a conductive susceptor that then heats the non-conductive material.

Coil Design and Cost

The induction coil is not a one-size-fits-all component. Each application requires a coil specifically engineered for the part's geometry and the desired heating pattern.

The design and manufacturing of these specialized copper inductors can be complex and represent a significant initial investment.

System Complexity

While the process is controllable, it is not simple. It requires a sophisticated power supply to manage the precise frequency and current needed for the application. Proper setup and engineering are critical to achieving consistent and efficient results.

Making the Right Choice for Your Process

Choosing induction heating depends entirely on your specific manufacturing or process goals.

- If your primary focus is precision and repeatability: Induction is unmatched for applications like surface hardening or brazing where the heat zone must be tightly controlled.

- If your primary focus is speed and high throughput: The rapid heating cycle of induction makes it ideal for automated production lines where cycle time is critical.

- If your primary focus is purity and material integrity: The non-contact nature of induction melting is the best choice for producing high-purity metals and alloys free from contamination.

Ultimately, induction heating is a powerful tool when its unique advantages align with the demands of your specific application.

Summary Table:

| Application | Key Benefit | Common Use Cases |

|---|---|---|

| Surface Hardening | Precise, localized heat for wear resistance | Gears, shafts, bearings |

| Metal Melting | High-purity, non-contact heating | Aerospace alloys, specialty metals |

| Brazing & Welding | Fast, repeatable joins with minimal distortion | Automotive, HVAC, electronics |

| Semiconductor Processing | Ultra-pure crystal growth | Silicon wafers, zone refining |

Ready to harness the power of induction heating for your application?

At KINTEK, we leverage our exceptional R&D and in-house manufacturing capabilities to provide advanced thermal processing solutions. Whether you need a standard system or a fully customized induction heating setup for unique requirements, our expertise ensures precision, efficiency, and reliability.

Contact us today to discuss how our solutions can enhance your process with speed, accuracy, and purity.

Get in touch with our experts to explore the perfect induction heating solution for your needs.

Visual Guide

Related Products

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

- Vacuum Induction Melting Furnace

- Molybdenum Disilicide MoSi2 Thermal Heating Elements for Electric Furnace

- Silicon Carbide SiC Thermal Heating Elements for Electric Furnace

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

People Also Ask

- What is the process of hot pressing? A Guide to Achieving Superior Material Density

- What are the main applications of vacuum hot pressing? Create Dense, Pure Materials for Demanding Industries

- How does the use of vacuum in hot-pressing affect the material processing? Achieve Denser, Purer, and Stronger Materials

- What other types of furnaces are related to hot pressing? Explore Key Thermal Processing Technologies

- What are the overall benefits of using hot pressing in manufacturing? Achieve Superior Performance and Precision