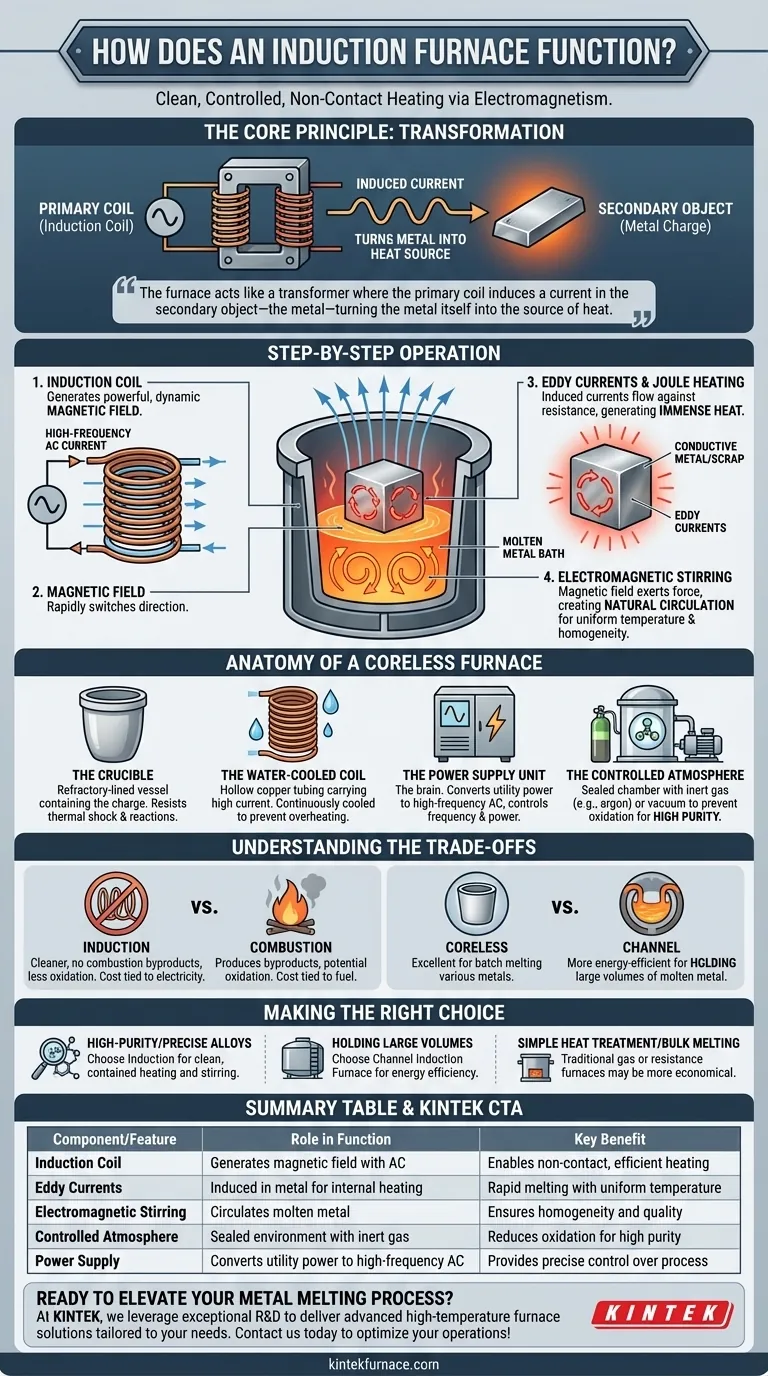

At its core, an induction furnace uses a powerful, fluctuating magnetic field to generate heat directly within the metal itself. It does not use flames or external heating elements to melt the charge, making it a clean and highly controlled process. The system works by passing a high-frequency alternating current through a copper coil, which induces intense electrical currents within the conductive metal, causing it to rapidly heat up and melt.

The fundamental principle is one of transformation. The furnace acts like a transformer where the primary coil induces a current in the secondary object—the metal—turning the metal itself into the source of heat.

The Core Principle: Heating Metal with Magnetism

An induction furnace's operation is based entirely on the principles of electromagnetism discovered by Michael Faraday. It is a non-contact heating method that is remarkably efficient and precise.

The Role of the Induction Coil

The process begins with the induction coil, typically made of water-cooled copper tubing. A specialized power supply sends a high-frequency alternating current (AC) through this coil.

As the current rapidly switches direction, it generates a powerful and dynamic magnetic field in the space within and around the coil.

Generating Heat Through Eddy Currents

When a conductive material, such as scrap metal or an ingot, is placed inside this magnetic field, the field induces circular electrical currents within the metal. These are known as eddy currents.

The metal has natural electrical resistance. As the strong eddy currents flow against this resistance, they generate immense heat through a process called Joule heating, melting the metal from the inside out.

The Advantage of Electromagnetic Stirring

A significant secondary effect of the magnetic field is that it exerts a force on the molten metal. This force creates a natural stirring or circulation pattern within the melt.

This electromagnetic stirring is crucial for producing high-quality metal, as it ensures temperatures are uniform throughout the bath and helps to thoroughly mix in alloying elements for a homogenous final product.

Anatomy of a Coreless Induction Furnace

The most common design is the coreless induction furnace. Its components are engineered for efficiency, safety, and control over the melting process.

The Crucible

The crucible is the refractory-lined vessel that contains the charge (the material to be melted). It must be made from a material, often a ceramic, that can withstand extreme thermal shock and resist chemical reaction with the molten metal.

The Water-Cooled Coil

Surrounding the crucible is the induction coil. Because it carries an extremely high current, the coil itself would quickly overheat and melt if not actively cooled. Water is continuously circulated through the hollow copper tubing to dissipate this waste heat.

The Power Supply Unit

The power supply is the brain of the system. It takes standard utility power and converts it into the high-frequency AC required by the coil, using a combination of transformers, inverters, and capacitor banks to control the precise frequency and power level.

The Controlled Atmosphere

Because no combustion is involved, induction furnaces can operate under a controlled atmosphere. The melting chamber can be sealed and filled with an inert gas like argon to prevent oxidation or placed under a vacuum to produce extremely high-purity metals.

Understanding the Trade-offs

While powerful, an induction furnace is not the universal solution for all heating applications. Its advantages are balanced by specific operational considerations.

Induction vs. Combustion Furnaces

Induction heating is significantly cleaner than fuel-fired furnaces, as it produces no combustion byproducts. This results in less metal loss to oxidation and a cleaner working environment, but the operational cost is tied to electricity prices rather than fuel prices.

Coreless vs. Channel Induction Furnaces

The coreless furnace is excellent for melting a wide variety of metals in batches. For holding large volumes of already molten metal, a channel induction furnace is often more energy-efficient. A channel furnace operates more like a true transformer, with an iron core focusing the magnetic field through a small loop or "channel" of molten metal.

Efficiency and Charge Material

Induction furnaces are most efficient when melting a full bath of material. Their efficiency can be lower when starting with a small amount of solid scrap, as the coupling between the magnetic field and the charge is less effective.

Making the Right Choice for Your Goal

The decision to use an induction furnace depends entirely on the material, the desired quality, and the scale of the operation.

- If your primary focus is high-purity melting or creating precise alloys: Induction is superior due to its clean, contained heating and natural stirring action.

- If your primary focus is holding large volumes of molten metal at temperature: A channel induction furnace is typically the most energy-efficient choice.

- If your primary focus is simple heat treatment or low-cost bulk melting: A traditional gas-fired or resistance-heated furnace might be a more economical solution.

Ultimately, choosing induction is choosing a high degree of control over the metallurgical process.

Summary Table:

| Component/Feature | Role in Function | Key Benefit |

|---|---|---|

| Induction Coil | Generates magnetic field with AC | Enables non-contact, efficient heating |

| Eddy Currents | Induced in metal for internal heating | Rapid melting with uniform temperature |

| Electromagnetic Stirring | Circulates molten metal | Ensures homogeneity and quality |

| Controlled Atmosphere | Sealed environment with inert gas | Reduces oxidation for high purity |

| Power Supply | Converts utility power to high-frequency AC | Provides precise control over process |

Ready to elevate your metal melting process with precision and efficiency? At KINTEK, we leverage exceptional R&D and in-house manufacturing to deliver advanced high-temperature furnace solutions tailored to your needs. Our product line includes Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, all backed by strong deep customization capabilities to meet your unique experimental requirements. Whether you're working with high-purity metals, precise alloys, or large-scale melting, KINTEK has the expertise to optimize your operations. Contact us today to discuss how our induction furnaces can transform your laboratory's performance and achieve superior results!

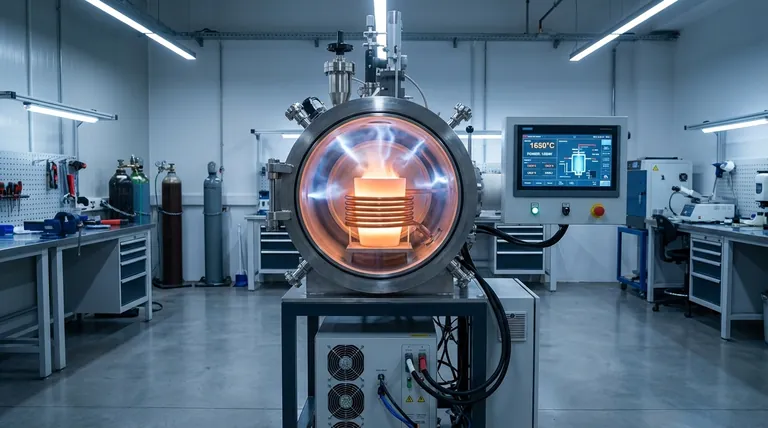

Visual Guide

Related Products

- Vacuum Induction Melting Furnace

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- Laboratory Muffle Oven Furnace with Bottom Lifting

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

People Also Ask

- How does the Vacuum Induction Melting (VIM) process work? Achieve Superior Metal Purity and Control

- What is the purpose of vacuum melting, casting and re-melting equipment? Achieve High-Purity Metals for Critical Applications

- What are the core functions of the High Vacuum Induction Melting (VIM) furnace? Optimize DD5 Superalloy Purification

- How does vacuum melting technology contribute to sustainability? Boost Durability and Recycling Efficiency

- What role does a vacuum induction melting furnace play in Fe-5%Mn-C alloys? Ensure Chemical Integrity and High Purity