Cold crucible induction levitation melting is primarily utilized to achieve exceptional purity and chemical homogeneity in TNZTSF alloys. By utilizing electromagnetic forces to suspend the molten metal, this technology effectively prevents the alloy from coming into physical contact with the crucible walls, eliminating the risk of contamination from the containment material.

Processing reactive titanium-based alloys requires overcoming the material's tendency to chemically react with its environment. Cold crucible induction levitation melting solves this by physically isolating the melt through electromagnetic suspension, ensuring the alloy retains the strict purity required for its intended mechanical and biological applications.

The Challenge of Reactivity

Titanium's Sensitivity

TNZTSF alloys rely heavily on titanium. However, titanium and its alloys are highly reactive metals, particularly when heated to melting temperatures.

The Problem with Standard Crucibles

In traditional melting processes, the molten metal sits directly against the crucible wall. Because of titanium's high reactivity, it can chemically attack the crucible material.

Contamination Risks

This interaction causes the crucible material to degrade and leach into the melt. This results in impurity absorption, which compromises the chemical composition of the final alloy.

The Mechanics of Levitation Melting

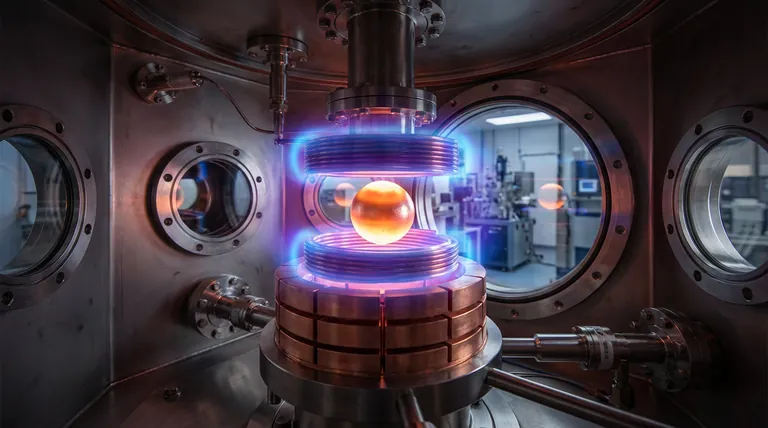

Electromagnetic Suspension

To solve the contact problem, cold crucible technology utilizes powerful electromagnetic forces. These forces effectively levitate the molten metal, suspending it in mid-air within the crucible.

Eliminating Contact

By suspending the melt, the process creates a physical gap between the hot alloy and the crucible walls. This ensures that the highly reactive molten metal never touches the container, removing the primary source of contamination found in conventional methods.

Ensuring Homogeneity

Beyond purity, the electromagnetic field stirs the molten metal. This agitation promotes chemical homogeneity, ensuring the alloying elements in the TNZTSF matrix are evenly distributed throughout the material.

The Role of Atmospheric Control

Protection from Gases

While levitation protects against the crucible, the alloy must still be protected from the air. A controlled high-purity argon atmosphere is essential during the melting and heat treatment phases.

Preventing Oxidation

Titanium alloys react aggressively with oxygen and nitrogen at elevated temperatures. The argon environment acts as a shield, preventing oxidation and the absorption of atmospheric impurities.

Criticality for Performance

This dual approach—levitation plus argon protection—is vital for preserving the material's properties. It maintains the biological compatibility and mechanical integrity that are essential for the performance of TNZTSF alloys.

Understanding the Process Constraints

The Necessity of Isolation

There is virtually no margin for error regarding contact. If the electromagnetic suspension fails or is unstable, the melt will contact the crucible, immediately reintroducing contamination risks.

Dependency on Atmosphere

Levitation alone is insufficient if the atmosphere is compromised. Even without crucible contact, a failure to maintain the high-purity argon environment will lead to immediate oxidation, rendering the alloy brittle and unsuitable for use.

Implications for Material Synthesis

Depending on your specific requirements for the TNZTSF alloy, the application of this technology impacts different performance metrics.

- If your primary focus is Biological Compatibility: This method is non-negotiable, as it eliminates crucible contaminants that could trigger adverse biological reactions.

- If your primary focus is Mechanical Integrity: The technology ensures a homogenous mixture free of oxides and nitrides, which are known to act as failure points in structural applications.

By combining electromagnetic isolation with atmospheric control, this synthesis method guarantees the production of high-purity alloys capable of meeting rigorous performance standards.

Summary Table:

| Feature | Advantage for TNZTSF Alloys |

|---|---|

| Electromagnetic Levitation | Prevents crucible contact, eliminating impurity absorption and contamination. |

| Atmospheric Control | Uses high-purity argon to prevent oxidation and nitrogen absorption. |

| Inductive Stirring | Promotes uniform chemical distribution for superior material homogeneity. |

| Material Integrity | Preserves biological compatibility and mechanical strength of reactive Ti-bases. |

Elevate Your Material Purity with KINTEK

For high-performance TNZTSF alloys, precision is not optional—it is essential. KINTEK provides the advanced thermal technology needed to master reactive metal synthesis. Backed by expert R&D and world-class manufacturing, we offer a comprehensive range of Muffle, Tube, Rotary, Vacuum, and CVD systems, along with specialized high-temperature lab furnaces.

Whether you require atmospheric control or customizable heating profiles for unique research needs, our systems ensure your materials retain their mechanical and biological integrity. Contact us today to discuss how our customizable solutions can optimize your lab's smelting and heat treatment processes.

References

- Vasile Dănuț Cojocaru, Bogdan Mihai Gălbinaşu. The Effect of Solution Treatment Duration on the Microstructural and Mechanical Properties of a Cold-Deformed-by-Rolling Ti-Nb-Zr-Ta-Sn-Fe Alloy. DOI: 10.3390/ma17040864

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Vacuum Induction Melting Furnace

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

- Laboratory Vacuum Tilt Rotary Tube Furnace Rotating Tube Furnace

- Split Chamber CVD Tube Furnace with Vacuum Station CVD Machine

People Also Ask

- How does the induction coil in a vacuum furnace work? Achieve Contamination-Free, Rapid Metal Heating

- What temperature range is required for melting and refining 3003mod aluminum alloys? Optimal 700–760 °C Guidelines

- Why is high-purity argon gas purging necessary during the melting of high-entropy alloys? Ensure Alloy Integrity

- What is electromagnetic induction used for in industrial applications? Achieve Fast, Precise Metal Heating

- What environmental benefits do induction furnaces provide? Achieve Cleaner, Safer Industrial Heating

- Why is vacuum environment important in VIM furnaces? Achieve High-Purity Alloys with Precision Control

- What is the primary function of a Vacuum Arc Furnace in the preparation of Ti-6Al-4V and Ti-6Al-7Nb alloys?

- How does a high-frequency induction heating system contribute to the surface hardening of steel? Enhance Wear Resistance