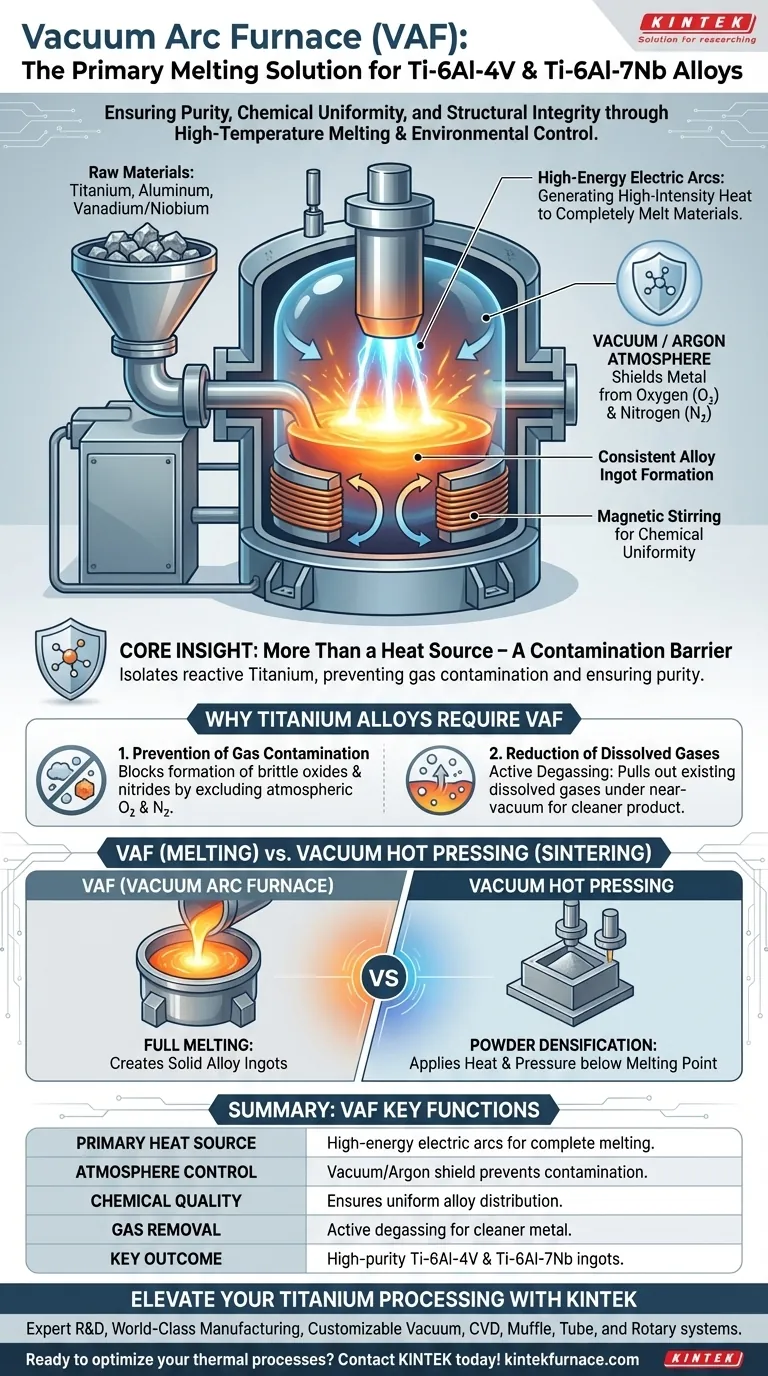

The Vacuum Arc Furnace (VAF) functions as the primary melting equipment in the production of Ti-6Al-4V and Ti-6Al-7Nb alloys. Its specific role is to generate the high temperatures needed to completely melt raw materials using high-energy electric arcs. By operating under a vacuum or argon atmosphere, it shields the metal to ensure chemical purity and structural integrity.

Core Insight: The VAF is not just a heat source; it is a contamination barrier. Its primary value lies in isolating highly reactive titanium from oxygen and nitrogen during the liquid phase, ensuring the final alloy is both pure and chemically uniform.

The Mechanics of Purity and Homogeneity

Generating High-Intensity Heat

The VAF utilizes high-energy electric arcs to create the extreme thermal conditions necessary for melting titanium alloys.

This process ensures that the raw materials transition completely from solid to liquid, which is the first step in creating a consistent alloy ingot.

Environmental Isolation

Melting occurs within a strictly controlled vacuum or argon protective atmosphere.

This environment is critical because titanium is highly reactive; without this protection, the metal would instantly react with atmospheric oxygen and nitrogen, compromising the material's properties.

Ensuring Chemical Uniformity

The VAF process promotes the uniform distribution of chemical components (Titanium, Aluminum, Vanadium, or Niobium) throughout the ingot.

In advanced configurations, such as magnetic-controlled furnaces, magnetic fields are used to stir the molten pool, further guaranteeing that the alloy's composition is consistent from edge to core.

Why Titanium Alloys Require VAF

Prevention of Gas Contamination

The most critical function of the VAF is preventing the formation of oxides and nitrides.

At high temperatures, titanium absorbs gases like oxygen and nitrogen, which makes the metal brittle and unusable. The VAF's protective atmosphere effectively blocks this reaction.

Reduction of Dissolved Gases

Beyond preventing new contamination, the VAF actively improves the metal's quality through degassing.

Exposure to low, near-vacuum pressure during the melting process pulls existing dissolved gases out of the molten metal, resulting in a cleaner final product.

Understanding the Trade-offs: Melting vs. Sintering

The Scope of the VAF

It is important to distinguish the VAF from other equipment like the Vacuum Hot Pressing Furnace.

The VAF is designed for full melting to create alloy ingots. It is not designed for powder metallurgy processes where materials are pressed and sintered at temperatures below their melting point.

Limitations of High-Temperature Processing

While VAF is excellent for purity, it requires careful management of consumables.

For example, when using carbon-containing tooling in related processes, barriers like boron nitride (BN) coatings are often required to prevent carbon diffusion, highlighting the extreme sensitivity of titanium at these temperatures.

Making the Right Choice for Your Goal

To select the correct processing method for your titanium alloy project, consider your specific end-state requirements:

- If your primary focus is creating solid, high-purity alloy ingots: Rely on the Vacuum Arc Furnace to fully melt the material and ensure chemical homogeneity while removing dissolved gases.

- If your primary focus is densifying powder without melting: Utilize a Vacuum Hot Pressing Furnace to apply heat and axial pressure simultaneously to induce diffusion creep.

The Vacuum Arc Furnace is the non-negotiable standard for establishing the fundamental chemical integrity of titanium alloys.

Summary Table:

| Feature | Function in Titanium Alloy Preparation |

|---|---|

| Primary Heat Source | High-energy electric arcs for complete melting of raw materials |

| Atmosphere Control | Vacuum or Argon shield to prevent oxygen/nitrogen contamination |

| Chemical Quality | Ensures uniform distribution of Al, V, or Nb throughout the ingot |

| Gas Removal | Active degassing to eliminate dissolved impurities for cleaner metal |

| Key Outcome | High-purity, structurally sound Ti-6Al-4V and Ti-6Al-7Nb ingots |

Elevate Your Titanium Processing with KINTEK

Precision and purity are non-negotiable when working with high-performance alloys like Ti-6Al-4V. Backed by expert R&D and world-class manufacturing, KINTEK offers a comprehensive range of Vacuum, CVD, Muffle, Tube, and Rotary systems, all fully customizable to meet your unique laboratory or production needs.

Whether you are melting high-purity ingots or exploring advanced powder metallurgy, our team provides the technical expertise and high-temperature furnace technology required to ensure your materials meet the most rigorous standards.

Ready to optimize your thermal processes? Contact KINTEK today to discuss your project requirements!

Visual Guide

References

- Ahmed H. Awad, Shimaa El‐Hadad. Studying the Behavior of Cast and Thermally Treated α + β -Titanium Alloys Using the Abbott Firestone Technique. DOI: 10.1007/s40962-024-01528-w

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Vacuum Heat Treat Sintering and Brazing Furnace

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- Molybdenum Vacuum Heat Treat Furnace

People Also Ask

- Why is a Vacuum Induction Melting furnace (VIM) used for Cu-Zn-Al-Sn alloys? Achieve Precision Composition Control

- What are the key advantages of using induction heating in manufacturing? Unlock Speed, Precision & Efficiency

- Where is induction heating commonly used? Discover Its Key Industrial and Commercial Applications

- What are the advantages of vacuum induction melting and casting (VIM&C) over VIM? Achieve Superior Metallurgical Quality and Efficiency

- What is a core type induction furnace? A Specialized Transformer for Efficient Metal Melting

- Why is preheating the mold to 300°C necessary for AZ91D casting? Optimize Structural Integrity and Grain Refinement

- What experimental environment does a vacuum induction furnace provide for HRB400? Ensure Ultra-Purity Steel Research

- What are the productivity benefits of using an induction gold melting furnace? Boost Output and Purity