At its core, induction heating offers a fundamental shift from traditional heating methods. Its key advantages in manufacturing are exceptional speed, precision, energy efficiency, and safety. These benefits are not isolated features; they all stem directly from its unique ability to generate heat inside the workpiece itself using electromagnetic principles, rather than relying on external flames or heating elements.

The true advantage of induction heating is not just that it's a better way to heat metal, but that it provides an unprecedented level of control over the heating process. This control is the source of its transformative impact on product quality, operational cost, and workplace safety.

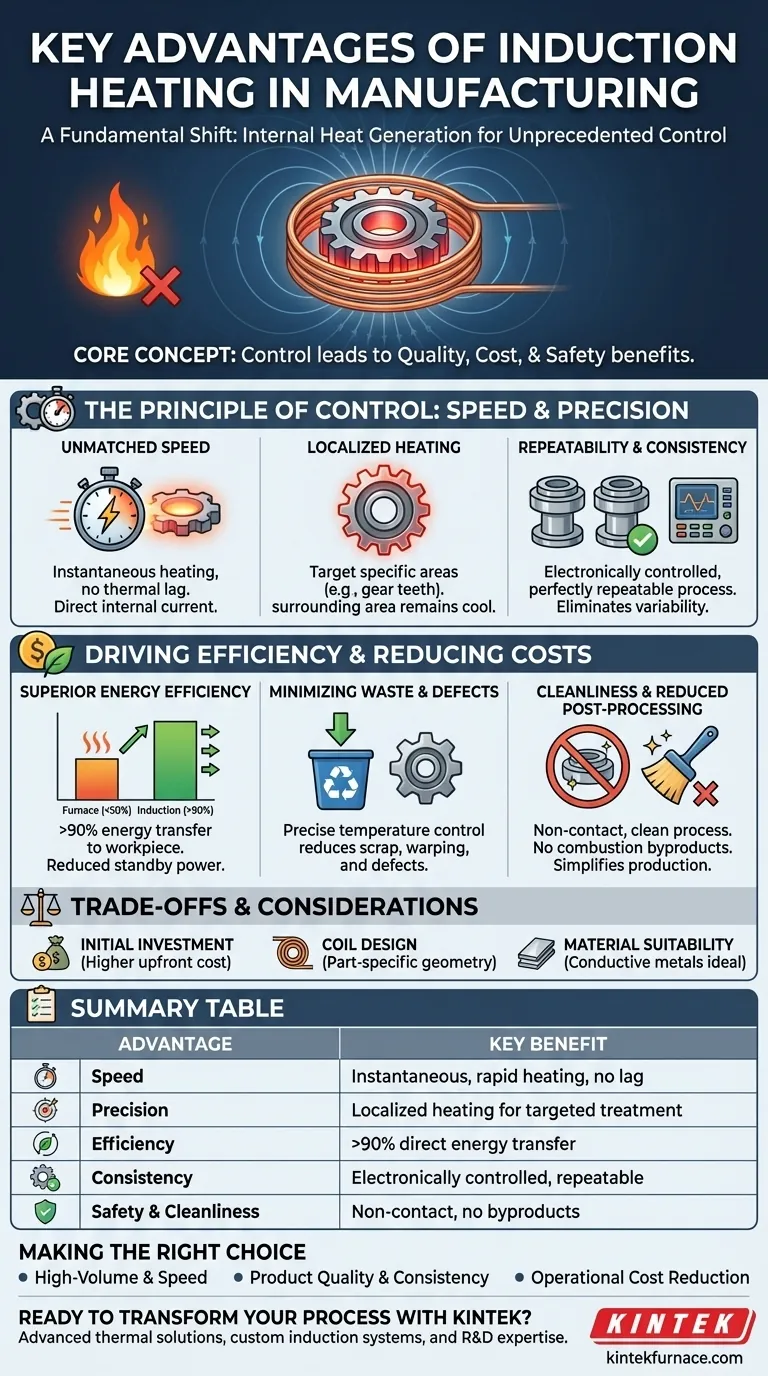

The Principle of Control: Speed and Precision

Induction heating’s primary benefit is the granular control it gives engineers. This control manifests as unmatched speed and the ability to apply heat with surgical precision.

How Induction Achieves Unmatched Speed

Traditional furnaces heat a part via conduction and convection, which is a slow process that requires heating the entire oven and the air inside it.

Induction heating is fundamentally different. It uses an alternating magnetic field to induce an electrical current directly within the conductive workpiece. This internal resistance creates instantaneous and rapid heat. There is no ramp-up time or thermal lag.

The Power of Localized Heating

Heat is only generated in the portion of the material placed inside the induction coil. This has two significant implications.

First, you can heat-treat a specific area of a part—like the teeth on a gear—without affecting the structural integrity of the rest of the component. Second, it keeps the surrounding equipment and environment cool, improving safety.

Repeatability and Process Consistency

Because the heating process is controlled electronically (by adjusting current, voltage, and frequency), it is perfectly repeatable.

Once a heating profile is established, you can be certain that the first part and the thousandth part have received the exact same thermal treatment. This eliminates the process variability common in conventional furnaces, leading to higher and more reliable product quality.

Driving Efficiency and Reducing Costs

The control offered by induction heating translates directly into tangible financial benefits through superior efficiency and waste reduction.

Superior Energy Efficiency

Conventional furnaces are notoriously inefficient, as a massive amount of energy is wasted heating the furnace walls and the air. Typical efficiencies can be below 50%.

Induction heating transfers over 90% of its energy directly into the workpiece. It only consumes significant power when a part is being heated, drastically reducing standby energy consumption and overall utility costs.

Minimizing Material Waste and Defects

The precise temperature control of induction heating minimizes the risk of overheating, warping, or creating a brittle structure.

By consistently delivering the right amount of heat to the right location, it dramatically reduces the scrap rate. This not only saves material costs but also the labor and energy costs sunk into defective parts.

Cleanliness and Reduced Post-Processing

Induction is a non-contact, clean heating process. It produces no combustion gases or byproducts that can contaminate the part's surface.

This often eliminates the need for subsequent cleaning or shot-blasting operations, simplifying the production line and reducing cycle time.

Understanding the Trade-offs and Considerations

While powerful, induction heating is not a universal solution. Acknowledging its limitations is key to making an informed decision.

Initial Capital Investment

Induction heating systems typically have a higher upfront purchase price compared to simple gas-fired furnaces.

This cost must be evaluated as a long-term investment, weighing it against the significant operational savings from reduced energy use, lower scrap rates, and increased throughput.

Coil Design and Geometry

The induction coil is the "tool" that delivers the energy, and its design is critical. Each coil must be carefully designed and fabricated to match the specific geometry of the part being heated.

This means that a system configured for one part may not work for another without a different coil, adding a layer of engineering and cost for high-mix manufacturing environments.

Material Suitability

Induction heating works by inducing current in electrically conductive materials. It is therefore ideal for metals like steel, copper, and aluminum.

While it can be adapted to heat non-conductive materials like plastics or composites by using a conductive "susceptor," it is not the most direct or efficient method for those applications.

Making the Right Choice for Your Process

The decision to adopt induction heating should be driven by a clear understanding of your primary manufacturing objective.

- If your primary focus is high-volume production and speed: Induction's instant-on nature and rapid heating cycles will dramatically increase your throughput and shorten lead times.

- If your primary focus is product quality and consistency: The precise, repeatable control of induction heating minimizes defects and ensures every part meets exact specifications.

- If your primary focus is operational cost reduction: The significant energy savings and reduced scrap rates offer a compelling long-term return on investment that often outweighs the initial capital cost.

By understanding its core principles, you can leverage induction heating not just as a tool, but as a strategic advantage in your manufacturing process.

Summary Table:

| Advantage | Key Benefit |

|---|---|

| Speed | Instantaneous, rapid heating with no thermal lag |

| Precision | Localized heating for targeted treatment |

| Efficiency | >90% energy transfer directly to the workpiece |

| Consistency | Electronically controlled, perfectly repeatable process |

| Safety & Cleanliness | Non-contact, no combustion byproducts |

Ready to transform your manufacturing process with the precision of induction heating?

At KINTEK, we leverage our exceptional R&D and in-house manufacturing capabilities to provide advanced thermal solutions for diverse industries. Our expertise in high-temperature furnace technology, including custom induction systems, allows us to deliver the speed, consistency, and efficiency your production line demands.

Let our engineers help you evaluate if induction heating is the right strategic advantage for your application. Contact us today for a personalized consultation and discover how we can optimize your heat treatment process.

Visual Guide

Related Products

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

- Molybdenum Disilicide MoSi2 Thermal Heating Elements for Electric Furnace

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- Laboratory Quartz Tube Furnace RTP Heating Tubular Furnace

- Laboratory Muffle Oven Furnace with Bottom Lifting

People Also Ask

- How does the use of vacuum in hot-pressing affect the material processing? Achieve Denser, Purer, and Stronger Materials

- What are the applications of hot pressing? Achieve Maximum Material Performance

- How is Vacuum Hot Press equipment used in R&D? Innovate with High-Purity Materials

- How does induction heating ensure precision in manufacturing processes? Achieve Superior Thermal Control & Repeatability

- What are some specific applications of vacuum hot press furnaces? Unlock Advanced Material Fabrication