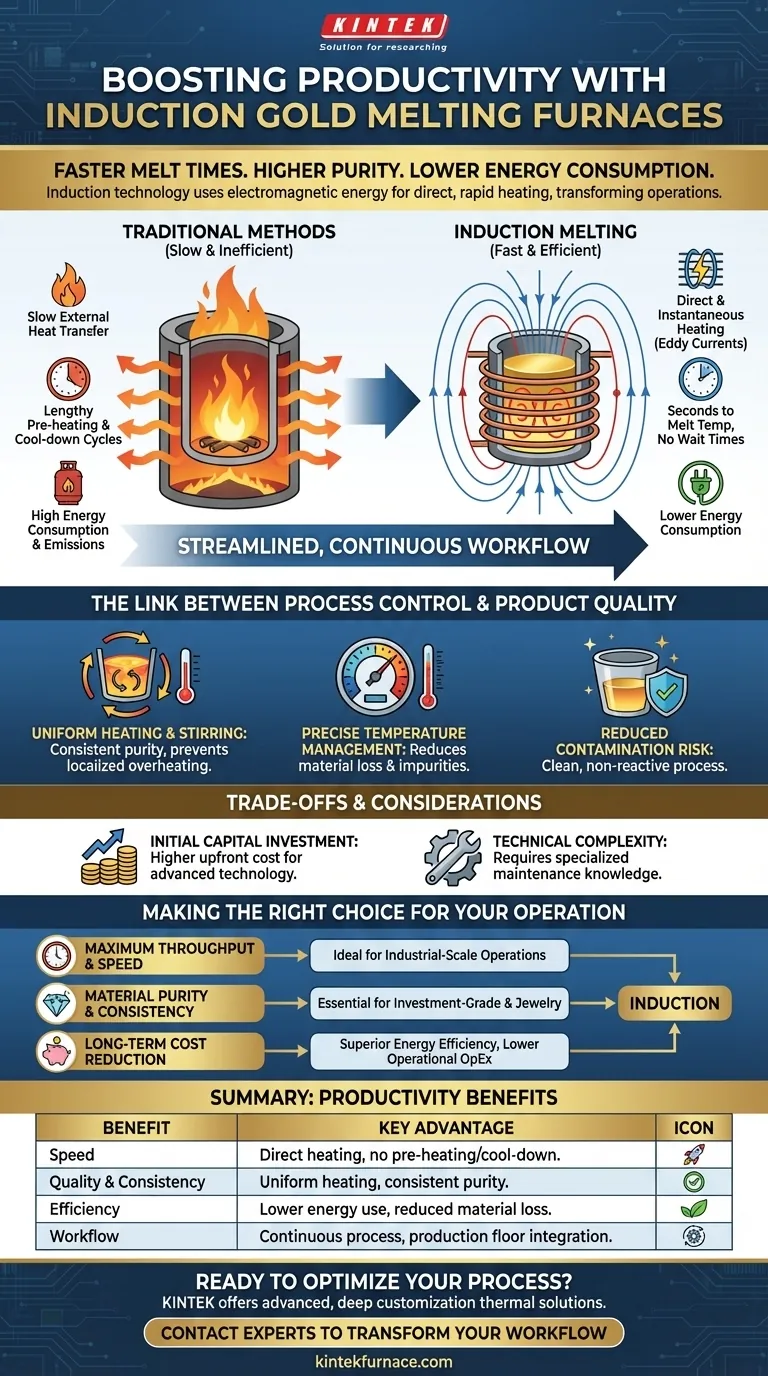

From a productivity standpoint, an induction gold melting furnace offers significant advantages by using electromagnetic energy to heat metal directly and rapidly. This process results in dramatically faster melt times, higher material purity, and lower energy consumption compared to traditional methods, directly translating to increased operational output and reduced costs.

The core productivity benefit of an induction furnace is not just its speed, but its ability to create a highly controlled, repeatable, and efficient melting process. This transforms the operation from a series of manual, variable steps into a streamlined, continuous workflow.

How Induction Drives Unmatched Speed

The primary productivity gain comes from the fundamental difference in how induction furnaces generate heat. They do not rely on external burners or heating elements.

Direct and Instantaneous Heating

An induction furnace uses a powerful, high-frequency magnetic field to generate electrical eddy currents directly within the gold itself. This internal friction creates intense, uniform heat almost instantly, eliminating the slow, inefficient heat transfer of traditional furnaces.

Eliminating Pre-heating and Cool-down Cycles

Conventional furnaces require lengthy pre-heating periods to reach temperature and extended cool-down times. Induction systems can reach melting temperatures in seconds and cool just as quickly, allowing for a near-continuous melting process without the delays of batch processing.

Continuous Workflow Integration

Because the process is flameless and self-contained, these furnaces can often be placed directly on the production floor. This eliminates the time and labor spent moving materials to and from a dedicated, fire-safe furnace room, further compressing the overall production cycle.

The Link Between Process Control and Product Quality

Productivity is not just about speed; it's also about reducing rework and waste. The precision of induction melting directly improves the quality and consistency of the final product.

Uniform Heating for Consistent Purity

The electromagnetic field naturally stirs the molten metal. This ensures the entire batch melts at a uniform temperature, preventing localized overheating (which can cause metal loss) and ensuring alloys are mixed thoroughly and consistently.

Precise Temperature Management

Induction systems offer exceptionally precise temperature control. This accuracy prevents burning off valuable metal and reduces the formation of impurities, resulting in a higher-yield, higher-purity final product with every melt.

Reduced Contamination Risk

Unlike combustion furnaces that can introduce impurities from fuel, induction is an entirely clean process. The heat is generated within the metal itself, which is contained in a non-reactive crucible, minimizing any risk of external contamination.

Understanding the Trade-offs and Considerations

While highly productive, induction technology is not a universal solution. A clear-eyed assessment of its limitations is crucial for making a sound investment.

Initial Capital Investment

The primary drawback is cost. Induction furnaces represent a significantly higher upfront capital expenditure compared to simpler propane or resistance-coil furnaces. The technology is more complex, involving advanced power electronics.

Technical Complexity and Maintenance

Modern induction furnaces, often using IGBT technology, are sophisticated electronic devices. While they feature protective circuits for reliability, maintenance and repair typically require more specialized knowledge than for a simple gas furnace.

Matching the Furnace to the Load

The efficiency of an induction furnace is highly dependent on the design of the coil and its relationship to the crucible's size and shape. A system optimized for melting 1kg of gold may be inefficient for melting 100g, meaning operations with highly variable loads must choose their equipment carefully.

Making the Right Choice for Your Operation

To determine if an induction furnace is the right choice, align its benefits with your primary operational goals.

- If your primary focus is maximum throughput and speed: Induction's rapid cycles and elimination of wait times are ideal for industrial-scale operations where output volume is the key metric.

- If your primary focus is material purity and consistency: The precise, uniform, and clean heating of induction is essential for creating investment-grade bars or high-quality jewelry where metal loss and contamination are unacceptable.

- If your primary focus is long-term operational cost reduction: The superior energy efficiency and reduced labor needs of induction can provide a strong return on investment by significantly lowering ongoing utility and operational expenses.

Ultimately, adopting an induction furnace is less about melting gold faster and more about fundamentally optimizing your entire production process for a new level of control and efficiency.

Summary Table:

| Productivity Benefit | Key Advantage |

|---|---|

| Speed | Direct, instantaneous heating; eliminates pre-heating/cool-down cycles. |

| Quality & Consistency | Uniform heating and electromagnetic stirring ensure consistent purity. |

| Efficiency | Lower energy consumption and reduced material loss/waste. |

| Workflow | Enables a near-continuous, streamlined process on the production floor. |

Ready to optimize your gold melting process for maximum productivity and purity?

At KINTEK, we leverage our exceptional R&D and in-house manufacturing to provide advanced thermal solutions for precious metal operations. Our high-temperature furnace expertise, including specialized induction systems, is complemented by strong deep customization capabilities. We can design a solution to precisely meet your unique requirements for throughput, purity, and efficiency.

Contact our experts today to discuss how a KINTEK furnace can transform your production workflow.

Visual Guide

Related Products

- Vacuum Induction Melting Furnace

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

People Also Ask

- What components make up a Vacuum Induction Melting Furnace? Discover the Key Systems for Pure Metal Melting

- What are the advantages of vacuum induction melting? Achieve Superior Purity for High-Performance Alloys

- What are the main applications of vacuum induction melting (VIM) furnaces? Achieve Unmatched Metal Purity for Critical Industries

- What are the key components of a Vacuum Induction Melting (VIM) furnace? Master High-Purity Metal Processing

- What are the key benefits of using vacuum melting furnaces? Achieve Superior Purity and Control for High-Performance Alloys