At its core, a core type induction furnace is an electric furnace that melts metal by acting like an electrical transformer. It uses an iron core to link a primary electrical winding to the metal charge itself, which acts as a a short-circuited secondary winding, causing intense heat to be generated directly within the metal.

The crucial concept to grasp is that a core type furnace uses an iron core to create a highly efficient, low-frequency magnetic link between the power source and the metal. This makes it fundamentally different from a coreless furnace and defines its specific applications.

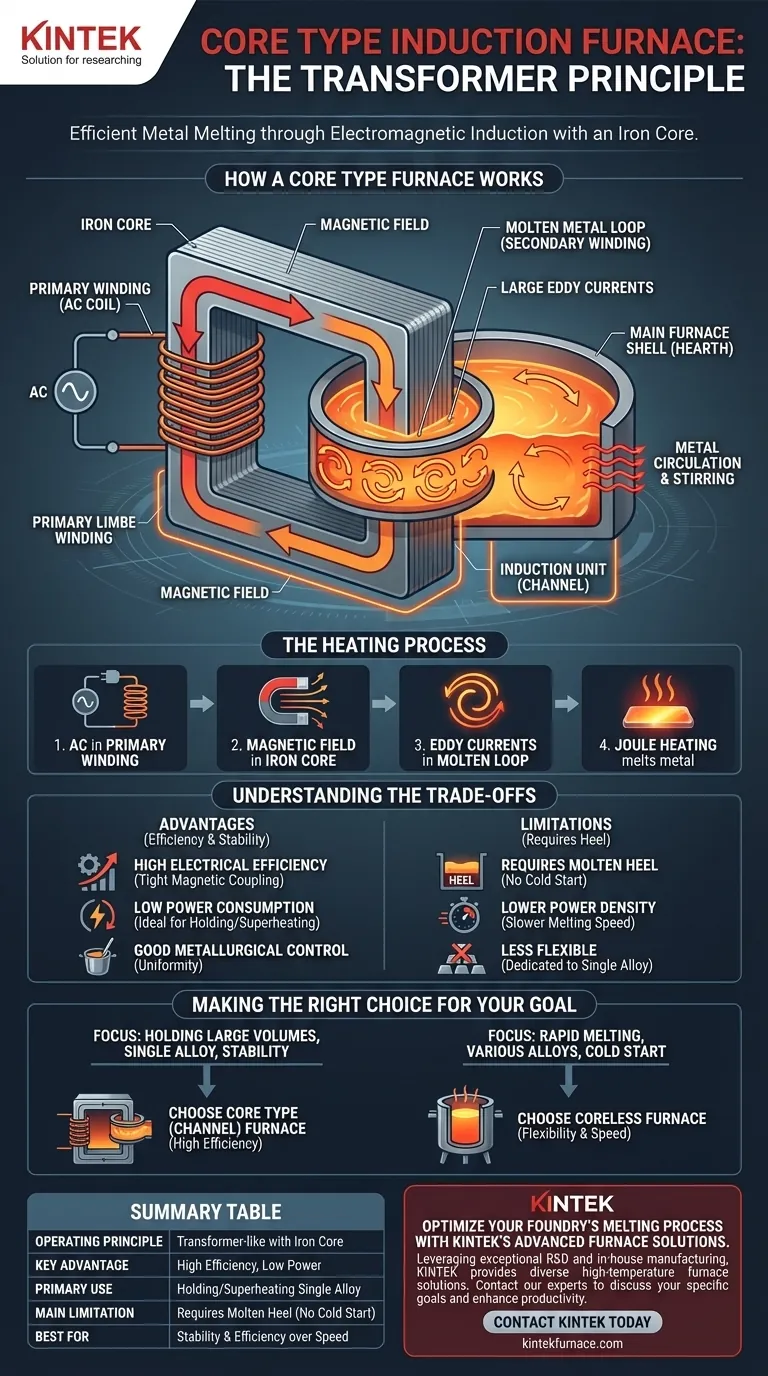

How a Core Type Furnace Works

A core type induction furnace operates on the principle of electromagnetic induction, a concept familiar to anyone who understands how a basic transformer functions. The goal is to convert electrical energy into heat within a metal charge.

The Transformer Analogy

Think of a standard transformer with two coils wrapped around an iron core. In a core type furnace:

- The Primary Winding: An electrical coil, powered by an AC source, is wound around a laminated iron core.

- The Iron Core: This core concentrates and directs the magnetic field created by the primary winding.

- The Secondary Winding: The metal to be melted is contained in a channel or ring that loops through the iron core. This ring of metal effectively becomes a single-turn, short-circuited secondary coil.

The Heating Process

- An alternating current (AC) is passed through the primary winding.

- This generates a powerful, alternating magnetic field that is concentrated by the iron core.

- The magnetic field induces a very large eddy current in the loop of conductive metal (the charge).

- The metal's natural electrical resistance opposes this strong current, generating immense heat (Joule heating) and causing the metal to melt.

Metal Circulation

A key advantage of this design is the natural stirring action it creates. The intense heat generated within the metal loop causes it to circulate into the main bath or hearth of the furnace. This movement ensures a more uniform temperature and consistent alloy composition throughout the molten bath.

Key Components and Design

The physical design of a core type furnace is built around its function as a transformer. It's often referred to as a channel furnace because of its distinct construction.

The Main Furnace Shell

This is the primary vessel, lined with refractory material, that holds the bulk of the molten metal.

The Induction Unit (The "Channel")

Attached to the main shell is the inductor assembly. This is where the heating happens. It contains the primary coil and the iron core, with a channel for the molten metal to loop through, completing the "secondary circuit."

Understanding the Trade-offs

No single technology is perfect for every application. The design of the core type furnace creates distinct advantages and limitations.

Advantages

- High Electrical Efficiency: The iron core creates a very tight magnetic coupling, resulting in less energy loss compared to coreless designs.

- Low Power Consumption: They are excellent for holding metal at a specific temperature for long periods or for superheating, as they consume less power in a steady state.

- Good Metallurgical Control: The gentle, continuous stirring ensures excellent mixing and temperature homogeneity.

Limitations

- Requires a Molten Heel: A core type furnace cannot be started from cold with solid metal. A continuous loop of molten metal must always be present in the channel to complete the secondary circuit. This is known as a "molten heel."

- Lower Power Density: They cannot melt metal as rapidly as coreless furnaces because the power that can be applied is limited by the channel's refractory lining.

- Less Flexible: They are not well-suited for frequent alloy changes, as the furnace must be completely drained, which is a complex process. They are typically dedicated to a single alloy.

Making the Right Choice for Your Goal

Selecting the correct furnace technology depends entirely on the operational requirements of the foundry or plant.

- If your primary focus is holding large volumes of a single alloy at temperature: The high efficiency and low power consumption of a core type (channel) furnace make it the ideal choice.

- If your primary focus is rapidly melting various alloys from a cold start: A coreless induction furnace is superior due to its flexibility and high power density.

Ultimately, understanding the core type furnace as a highly specialized transformer allows you to recognize its unique strengths in applications demanding efficiency and stability over speed and flexibility.

Summary Table:

| Feature | Core Type Induction Furnace |

|---|---|

| Operating Principle | Functions like a transformer with an iron core |

| Key Advantage | High electrical efficiency and low power consumption |

| Primary Use | Holding and superheating large volumes of a single alloy |

| Main Limitation | Requires a molten heel; cannot start from cold |

| Best For | Foundries focused on stability and efficiency over speed |

Optimize your foundry's melting process with KINTEK's advanced furnace solutions.

Leveraging exceptional R&D and in-house manufacturing, KINTEK provides diverse laboratories and foundries with advanced high-temperature furnace solutions. Our product line, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, is complemented by our strong deep customization capability to precisely meet unique operational requirements like yours.

Whether you need the high-efficiency stability of a core-type furnace or the flexibility of a coreless design, our experts can help you select or customize the perfect solution. Contact our team today to discuss your specific metal melting goals and discover how KINTEK can enhance your productivity and efficiency.

Visual Guide

Related Products

- Vacuum Induction Melting Furnace

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- Laboratory Muffle Oven Furnace with Bottom Lifting

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

People Also Ask

- What are some common applications of vacuum induction melting and casting (VIM&C)? Essential for Aerospace, Medical, and Nuclear Industries

- What is vacuum induction melting technology and why is it important? Achieve High-Purity Metals for Critical Applications

- What are the core functions of the High Vacuum Induction Melting (VIM) furnace? Optimize DD5 Superalloy Purification

- How has vacuum smelting impacted the development of superalloys? Unlock Higher Strength and Purity

- How does the Vacuum Induction Melting (VIM) process work? Achieve Superior Metal Purity and Control