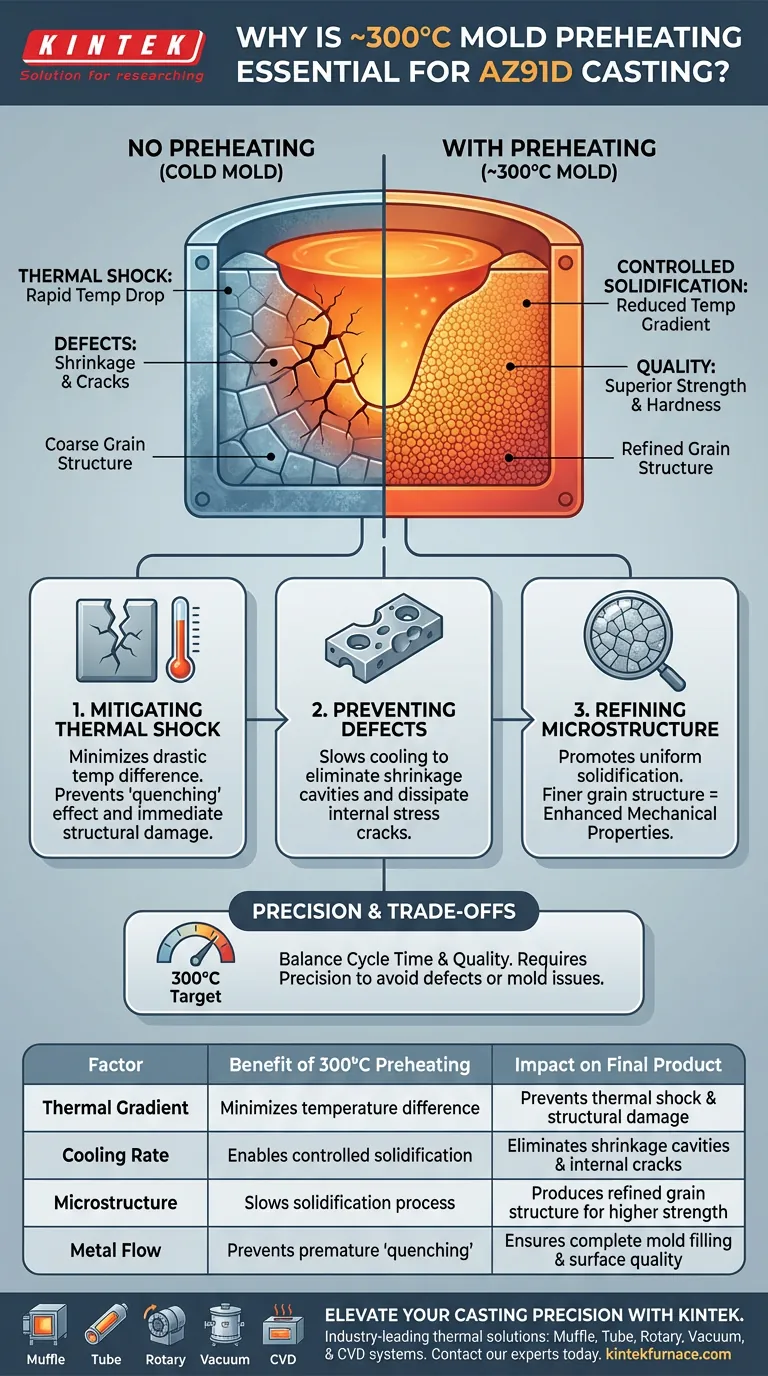

Preheating the mold to approximately 300°C is a fundamental requirement in AZ91D composite casting to minimize the drastic temperature differential between the molten metal and the mold surface. This thermal management strategy effectively reduces thermal shock, preventing immediate structural damage during the pour.

By acting as a thermal buffer, preheating slows the cooling rate to create a controlled solidification environment. This prevents critical defects like cracks and shrinkage while actively refining the metal's grain structure for superior strength.

The Role of Thermal Management in Casting

Mitigating Thermal Shock

When molten AZ91D contacts a cold surface, the rapid temperature drop creates immense internal stress. Preheating the mold to 300°C reduces this temperature gradient significantly.

This prevents the "quenching" effect that occurs when liquid metal hits a cold mold. By softening this initial impact, you protect the casting from immediate structural compromise.

Preventing Casting Defects

A regulated mold temperature is the primary defense against common physical flaws. Specifically, it prevents the formation of shrinkage cavities, which occur when metal contracts unevenly during rapid cooling.

It also creates a defense against cracking. By ensuring the metal does not solidify too aggressively, the internal stresses that typically fracture the material are dissipated.

Refining Microstructure

The mechanical properties of the finished composite are dictated by how the metal solidifies. A preheated mold ensures a slower, more uniform cooling process.

This controlled environment promotes a refined grain structure. A finer grain directly correlates to enhanced mechanical properties, specifically increasing both the tensile strength and hardness of the composite.

Understanding the Process Trade-offs

Balancing Cycle Time and Quality

While preheating is essential for quality, it introduces an additional variable to the production cycle. It requires time and energy to reach and maintain the 300°C target before casting can begin.

Temperature Precision

The target of 300°C is specific to the properties of AZ91D. Failing to reach this temperature risks thermal shock defects.

Conversely, overheating the mold can introduce other issues, such as sticking or mold degradation. Adherence to the specific temperature window is critical for consistency.

Making the Right Choice for Your Goal

To optimize your AZ91D casting process, align your thermal strategy with your specific quality requirements.

- If your primary focus is Structural Integrity: Ensure the mold reaches the full 300°C to eliminate the risk of shrinkage cavities and stress cracks.

- If your primary focus is Mechanical Performance: Prioritize the consistency of the mold temperature to guarantee the refined grain structure necessary for maximum hardness and tensile strength.

Mastering the preheat temperature is not merely a setup step; it is the defining factor in the reliability and longevity of the final composite.

Summary Table:

| Factor | Benefit of 300°C Preheating | Impact on Final Product |

|---|---|---|

| Thermal Gradient | Minimizes temperature difference | Prevents thermal shock and structural damage |

| Cooling Rate | Enables controlled solidification | Eliminates shrinkage cavities and internal cracks |

| Microstructure | Slows solidification process | Produces refined grain structure for higher strength |

| Metal Flow | Prevents premature "quenching" | Ensures complete mold filling and surface quality |

Elevate Your Composite Casting Precision with KINTEK

Achieving the perfect 300°C thermal environment is essential for high-performance AZ91D composites. KINTEK provides industry-leading thermal solutions designed to meet the rigorous demands of material science and industrial casting.

Backed by expert R&D and manufacturing, KINTEK offers a comprehensive range of Muffle, Tube, Rotary, Vacuum, and CVD systems, as well as specialized lab high-temperature furnaces—all fully customizable to your unique casting requirements.

Ready to eliminate defects and refine your material grain structure? Contact our experts today to find the ideal thermal management system for your laboratory or production line.

Visual Guide

References

- Shubham Sharma, Emad A. A. Ismail. Enhancing tribo-mechanical, microstructural morphology, and corrosion performance of AZ91D-magnesium composites through the synergistic reinforcements of silicon nitride and waste glass powder. DOI: 10.1038/s41598-024-52804-y

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- 1400℃ Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

People Also Ask

- What is the capacity range of induction furnaces? From 1kg to 100+ tons for any production goal

- What types of metals can a medium frequency induction furnace process? Melt Everything from Steel to Gold

- Why is a water-cooled copper crucible used for Sm-Co-Fe alloys? Ensuring Purity in Vacuum Arc Furnaces

- What is the role of a Vacuum Induction Melting (VIM) furnace in Invar 36 production? Ensure Purity & Precision

- What is the role of a vacuum induction furnace in MRDO preparation? Enabling Rare Earth Magnet Recycling

- How do vacuum melting furnaces contribute to the preparation of high-purity medium-manganese steel ingots?

- What materials can be heated using induction heating? Unlock Efficient Heating for Metals and More

- What are some common applications of induction furnace heating? Achieve Fast, Precise, and Clean Thermal Processing