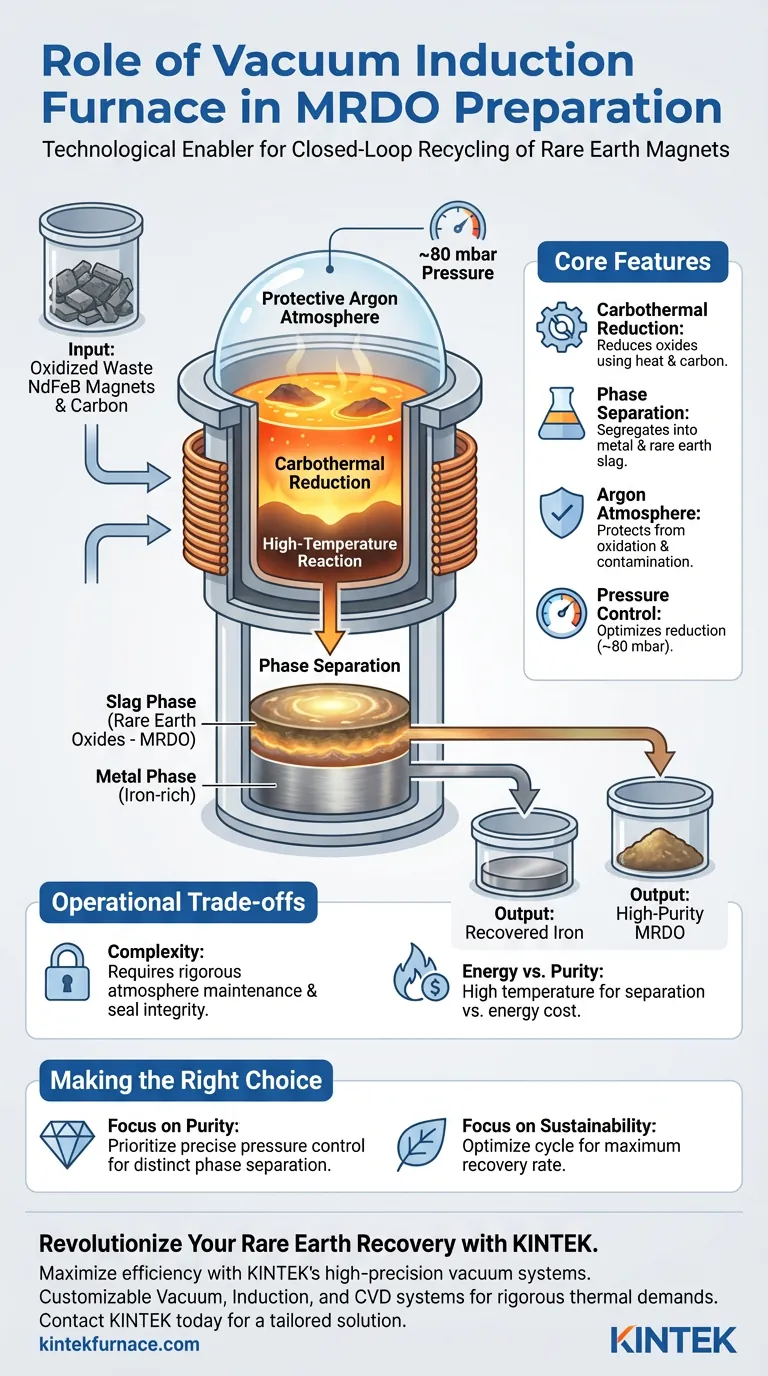

In the preparation of Magnet-Recycled Derived Oxides (MRDO), the vacuum induction furnace serves as the critical reaction vessel for the carbothermal reduction of oxidized waste Neodymium-Iron-Boron (NdFeB) magnets. By maintaining a high-temperature environment under a controlled protective atmosphere, the furnace enables the physical and chemical separation of iron-rich metals from the valuable rare earth oxides.

Core Takeaway The vacuum induction furnace is the technological enabler for closed-loop recycling of rare earth magnets. It facilitates the distinct separation of the metal phase from the oxide slag phase, transforming end-of-life magnetic waste into high-purity raw materials suitable for reuse.

The Mechanics of Separation

To understand the furnace's role, you must look beyond simple heating. It acts as a precise separator of chemical phases.

Facilitating Carbothermal Reduction

The primary function of the furnace is to drive carbothermal reduction.

This chemical process treats oxidized waste magnets, using carbon and heat to reduce the metal oxides found in the scrap material.

Distinct Phase Separation

The ultimate goal of this thermal process is segregation.

The high temperatures achieved within the furnace cause the material to separate into two distinct layers: a metal phase (predominantly iron) and a slag phase (rich in rare earth oxides).

This physical separation is the defining step that allows for the recovery of the rare earth elements (the "MRDO") separate from the iron waste.

Environmental Control

The success of this process relies heavily on the furnace's ability to manipulate the atmospheric environment surrounding the melt.

Protective Argon Atmosphere

You cannot perform this process in open air.

The furnace operates under a protective argon atmosphere to prevent unwanted oxidation from atmospheric oxygen, which would degrade the quality of the recovered materials.

Controlled Pressure Regulation

Precise pressure control is equally vital.

The system typically operates at reduced pressures, such as 80 mbar. This specific pressure environment is engineered to optimize the reduction reaction and ensure the efficient formation of the slag and metal phases.

Understanding the Trade-offs

While the vacuum induction furnace is essential for this recycling method, it introduces specific operational constraints that must be managed.

Complexity of Atmosphere Maintenance

The process is intolerant of atmospheric leaks.

Maintaining the specific 80 mbar argon environment requires rigorous seal integrity and pumping systems. Any breach introduces oxygen that can contaminate the metal phase or alter the stoichiometry of the rare earth oxides.

Energy vs. Purity

Achieving the high temperatures required for effective phase separation is energy-intensive.

Operators must balance the energy input against the yield of the rare earth oxides. Insufficient heat leads to incomplete separation (slag entrapment in metal), while excessive heat increases operational costs without proportionally increasing yield.

Making the Right Choice for Your Goal

When implementing a vacuum induction process for MRDO preparation, your operational parameters should be dictated by your specific recovery targets.

- If your primary focus is Purity of Rare Earth Oxides: Prioritize precise pressure control (e.g., strictly maintaining 80 mbar) to ensure the slag phase is completely distinct from the iron-rich metal phase.

- If your primary focus is Process Sustainability: Focus on the "closed-loop" aspect by optimizing the carbothermal reduction cycle to maximize the recovery rate of end-of-life products relative to energy input.

The vacuum induction furnace is not just a heater; it is the precision tool that unlocks the value hidden in magnetic waste.

Summary Table:

| Feature | Role in MRDO Preparation |

|---|---|

| Carbothermal Reduction | Uses heat and carbon to reduce oxides in waste NdFeB magnets. |

| Phase Separation | Segregates material into iron-rich metal and rare earth oxide slag. |

| Argon Atmosphere | Protects the melt from oxidation and contamination. |

| Pressure Control | Maintains ~80 mbar to optimize reduction and separation efficiency. |

Revolutionize Your Rare Earth Recovery with KINTEK

Maximize the efficiency of your closed-loop recycling with KINTEK’s high-precision vacuum systems. Backed by expert R&D and manufacturing, we provide customizable Vacuum, Induction, and CVD systems designed to meet the rigorous thermal and atmospheric demands of MRDO preparation. Whether you are scaling up carbothermal reduction or refining high-purity rare earth oxides, our lab high-temp furnaces offer the reliability your research demands.

Ready to optimize your recycling process? Contact KINTEK today for a tailored solution.

Visual Guide

References

- Greenhouse Gas Emissions from Molten Fluoride Electrolysis Composed of Raw and Magnet Recycling Derived Oxides: A Comparative Study. DOI: 10.3390/ma18010184

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Molybdenum Vacuum Heat Treat Furnace

- Vacuum Heat Treat Sintering and Brazing Furnace

People Also Ask

- Why are IGBT modules preferred in melting machines? Unlock Faster Melting & Lower Costs

- What are the benefits of the compact and lightweight design of induction furnaces? Maximize Efficiency in Limited Space

- What are the three main components of a vacuum induction melting furnace? Key Systems for Pure Metal Production

- What industries commonly use melt furnaces? Key Applications in Metal, Aerospace, and More

- Why is repeated flipping and remelting necessary when producing Sm-Co-Fe alloy ingots in an arc furnace? Key Insights

- What is an IGBT induction melting machine? Unlock Faster, More Efficient Metal Melting

- What is the role of the vacuum system in a vacuum casting furnace? Ensure Purity and Performance in Metal Casting

- What industries commonly use induction melting furnaces? Achieve High-Purity Metal Melting