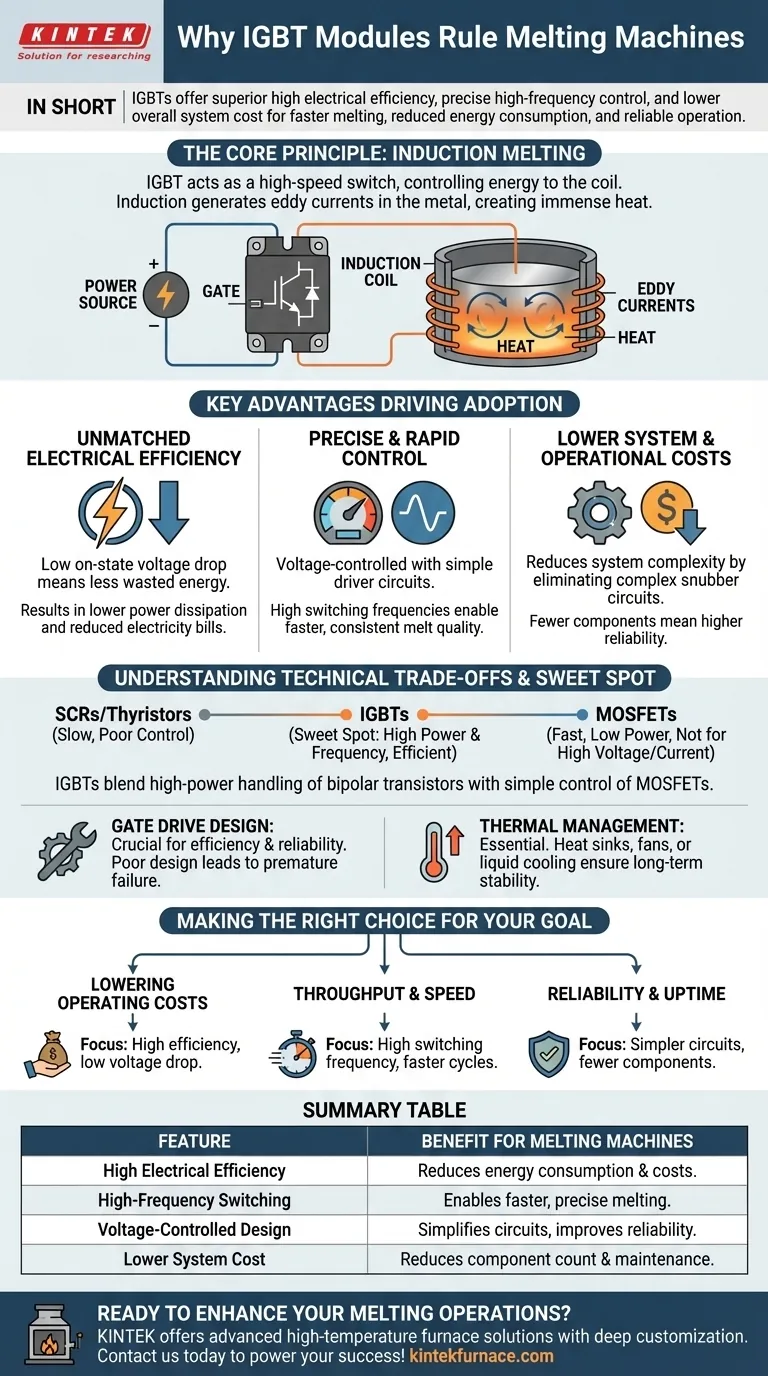

In short, IGBT (Insulated Gate Bipolar Transistor) modules are preferred in modern melting machines because they offer a superior combination of high electrical efficiency, precise high-frequency control, and lower overall system cost. This allows for faster melting, reduced energy consumption, and more reliable operation compared to older technologies.

The core reason for the dominance of IGBTs is that they uniquely blend the high-current, high-voltage handling capabilities of older bipolar transistors with the simple, low-power control of MOSFETs, creating the ideal switch for high-power induction heating.

The Core Principle: How IGBTs Power Induction Melting

To understand why IGBTs are the component of choice, we must first look at how an induction furnace works and the critical role the power-switching component plays.

Turning Electricity into Heat

An induction furnace doesn't use a traditional heating element. Instead, it uses a high-power coil to generate a powerful, rapidly changing magnetic field.

When conductive material like steel or aluminum is placed inside this field, it induces strong electrical currents within the metal itself, known as eddy currents. The metal's own electrical resistance causes these currents to generate immense heat, melting it from the inside out.

The Role of the IGBT as a High-Speed Switch

The entire process depends on a device that can switch massive amounts of electrical current on and off thousands of times per second to create the alternating magnetic field. This is the job of the IGBT module.

The IGBT acts as an incredibly fast and robust electronic switch, precisely controlling the flow of energy to the induction coil. Its performance directly dictates the efficiency and control of the entire melting process.

Key Advantages Driving IGBT Adoption

The features of IGBTs translate directly into tangible operational and financial benefits, making them the industry standard over older technologies like SCRs (Silicon-Controlled Rectifiers).

Unmatched Electrical Efficiency

The primary goal of any furnace is to turn electricity into heat with minimal waste. IGBTs excel here due to their low on-state voltage drop.

This means that when the IGBT switch is "on," it presents very little resistance to the high current flowing through it. This results in very low power dissipation, meaning less energy is wasted as heat within the control cabinet and more is delivered to the metal.

Precise and Rapid Control

IGBTs are voltage-controlled devices. This means they require very little power to be switched on or off, which simplifies the driver circuits needed to control them. Simpler circuits are inherently more reliable and less expensive.

Furthermore, IGBTs can operate at very high switching frequencies. This speed allows for finer, more responsive control over the heating process, enabling more consistent melt quality and faster cycle times.

Lower System and Operational Costs

The technical advantages of IGBTs lead directly to a lower total cost of ownership.

Higher efficiency means lower electricity bills for every ton of metal melted. The ability to operate without complex snubber circuits (which were required to protect older, slower components) reduces system complexity, component count, and potential points of failure.

Understanding the Technical Trade-offs

While IGBTs are the superior choice for this application, it's important to understand where they fit in the landscape of power electronics. No component is perfect for every scenario.

Why Not Other Transistors?

Older technologies like SCRs or thyristors are rugged but are very slow and difficult to turn off, offering poor process control.

On the other end, MOSFETs are extremely fast but typically cannot handle the very high voltages and currents required for large industrial melting furnaces as effectively as IGBTs. The IGBT occupies a "sweet spot" of high power and high-frequency capability.

The Importance of Gate Drive Design

While the driver circuits for IGBTs are simpler than for older technologies, their design is still critical. A poorly designed gate drive can lead to inefficient switching, increased electrical stress, and premature failure of the IGBT module. Proper implementation is key to unlocking their full potential.

Thermal Management Is Still Key

Even with high efficiency, the small percentage of energy lost as heat within the IGBT module is significant in high-power systems. Effective thermal management—using heat sinks, fans, or liquid cooling—is non-negotiable to ensure long-term reliability and stable performance across a wide temperature range.

Making the Right Choice for Your Goal

The decision to use or upgrade to IGBT-based systems depends on your primary operational driver.

- If your primary focus is lowering operating costs: The high efficiency from a low on-state voltage drop is the key feature, as it directly reduces your kilowatt-hour consumption.

- If your primary focus is throughput and speed: The high switching frequency is your main advantage, allowing for rapid and precise energy delivery to achieve faster melt cycles.

- If your primary focus is reliability and uptime: The simpler, voltage-controlled driver circuits and the elimination of snubber circuits reduce system complexity and common points of failure.

Ultimately, IGBTs empower furnace operators with a level of efficiency and control that directly improves the bottom line.

Summary Table:

| Feature | Benefit for Melting Machines |

|---|---|

| High Electrical Efficiency | Reduces energy consumption and operating costs. |

| High-Frequency Switching | Enables faster, more precise melting cycles. |

| Voltage-Controlled Design | Simplifies driver circuits, improving reliability. |

| Lower System Cost | Reduces component count and maintenance needs. |

Ready to enhance your melting operations with advanced thermal solutions?

At KINTEK, we leverage our exceptional R&D and in-house manufacturing to provide diverse laboratories with advanced high-temperature furnace solutions. Our product line, including Muffle, Tube, and Rotary Furnaces, is complemented by strong deep customization capabilities to precisely meet your unique experimental and production requirements.

Whether you're focused on lowering operating costs, increasing throughput, or maximizing uptime, our expertise can help you achieve superior results. Contact us today to discuss how our tailored furnace solutions can power your success!

Visual Guide

Related Products

- Vacuum Induction Melting Furnace

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

People Also Ask

- How is operator safety ensured during the vacuum induction melting process? Discover Multi-Layered Protection for Your Lab

- What industries benefit from Vacuum Induction Melting Furnaces? Unlock High-Purity Metals for Aerospace, Medical, and More

- What are the key features and benefits of a Vacuum Induction Melting Furnace? Achieve High-Purity Metal Production

- What are the key benefits of using vacuum melting furnaces? Achieve Superior Purity and Control for High-Performance Alloys

- How does vacuum induction melting work? Achieve Ultra-Pure, High-Performance Alloys