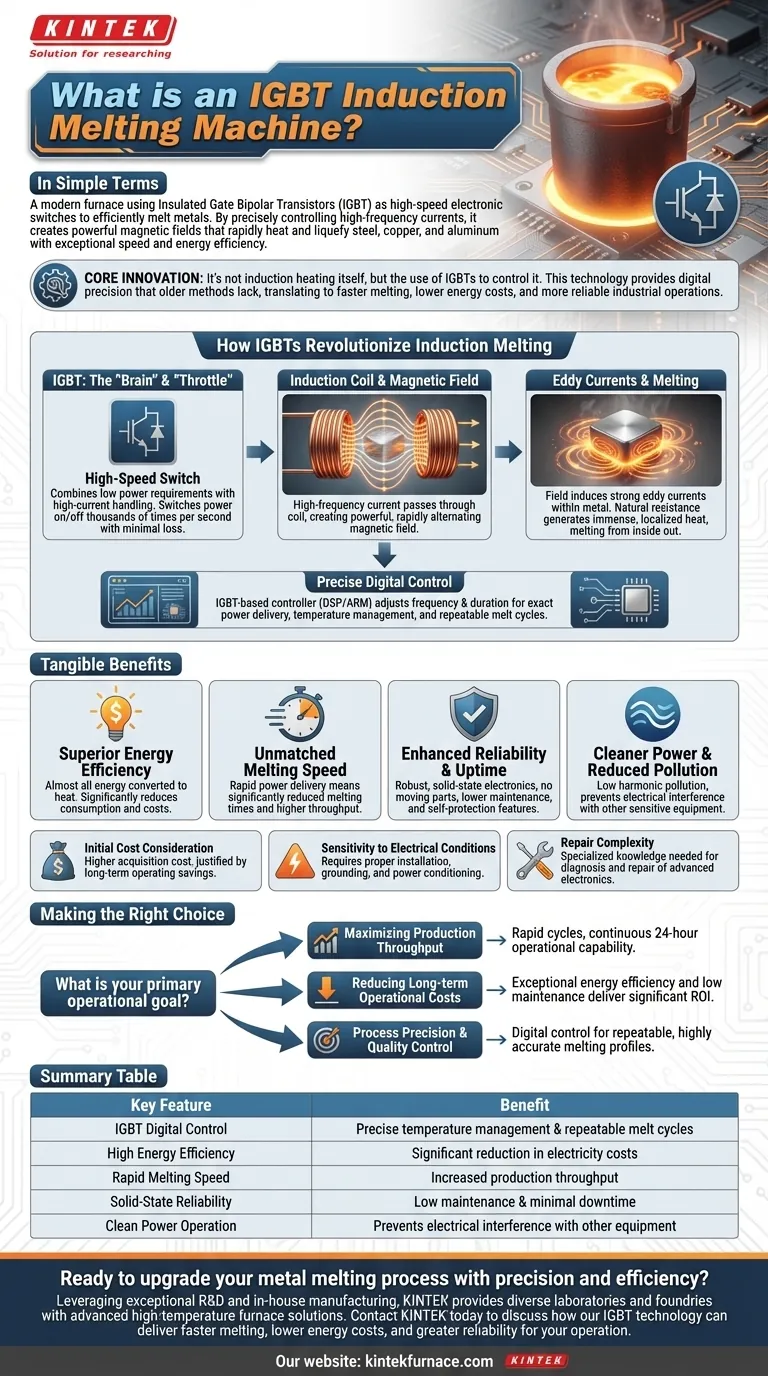

In simple terms, an IGBT induction melting machine is a modern furnace that uses a specific type of high-speed electronic switch—the Insulated Gate Bipolar Transistor (IGBT)—to efficiently melt metals. By precisely controlling high-frequency electrical currents, these machines create a powerful magnetic field that rapidly heats and liquefies metals like steel, copper, and aluminum with exceptional speed and energy efficiency.

The core innovation is not induction heating itself, but the use of IGBTs to control it. This technology provides a level of digital precision that older methods lack, translating directly into faster melting, lower energy costs, and more reliable industrial operations.

How IGBTs Revolutionize Induction Melting

To understand the value of an IGBT furnace, you must first understand the role of its central component. It's the "brain" and "throttle" of the entire system.

The Role of the IGBT as a High-Speed Switch

An IGBT, or Insulated Gate Bipolar Transistor, is a powerful semiconductor device. Think of it as an incredibly fast and robust digital light switch for very high electrical currents.

It combines the low power requirements of a MOSFET (another type of transistor) with the high-current handling capacity of a bipolar transistor. This allows it to switch massive amounts of power on and off thousands of times per second with minimal energy loss.

Generating Heat Through Induction

The furnace works by passing the high-frequency alternating current, managed by the IGBT, through a copper coil. This creates a powerful and rapidly alternating magnetic field inside the coil.

When a conductive metal is placed within this field, the field induces strong electrical currents within the metal itself, known as eddy currents. The metal's natural resistance to these currents generates immense, localized heat, causing it to melt quickly from the inside out.

The Power of Precise Control

This is where the IGBT's function becomes critical. By precisely adjusting the switching frequency and duration, the IGBT-based controller (often a DSP or ARM processor) dictates the exact amount of power delivered to the coil.

This digital control allows for exact temperature management, repeatable melt cycles, and the ability to adapt to different metals and load sizes instantly. It's the difference between using a sledgehammer and a surgical scalpel.

The Tangible Benefits in Industrial Applications

The technical advantages of IGBTs translate directly into measurable improvements on the factory floor.

Superior Energy Efficiency

Because IGBTs switch power so cleanly and with minimal waste, almost all the electrical energy drawn from the grid is converted into useful heat in the metal. This dramatically reduces energy consumption compared to older resistance or fuel-fired furnaces, leading to significant cost savings.

Unmatched Melting Speed and Throughput

The ability to deliver a high concentration of power rapidly means melting times are significantly reduced. Faster melt cycles lead directly to higher production throughput, allowing a facility to process more material in less time.

Enhanced Reliability and Uptime

IGBT technology is based on robust, solid-state electronics with no moving parts. This results in far greater reliability and lower maintenance requirements than older systems. Features like built-in self-protection also prevent damage from electrical faults, minimizing costly downtime.

Cleaner Power and Reduced Pollution

A key, often overlooked, benefit is low harmonic pollution. This means the furnace draws power from the electrical grid in a "clean" and stable way, preventing electrical interference that can disrupt other sensitive equipment in the facility.

Understanding the Trade-offs

No technology is without its considerations. An objective assessment requires acknowledging the potential downsides.

Initial Cost Consideration

IGBT induction systems are advanced technology. Their initial acquisition cost can be higher than that of simpler, less efficient furnace types. The investment is justified by the lower long-term operating costs from energy savings and increased productivity.

Sensitivity to Electrical Conditions

Like most high-performance digital electronics, the control systems in these furnaces can be sensitive to severe power surges or poor power quality. Proper installation, grounding, and sometimes power conditioning equipment are necessary to ensure optimal performance and longevity.

Repair Complexity

While highly reliable, the advanced components of an IGBT system require specialized knowledge to diagnose and repair. A failure in a controller or power module is not a simple mechanical fix and typically requires a trained technician for service.

Making the Right Choice for Your Operation

Choosing an IGBT induction furnace is a strategic decision based on your primary operational goals.

- If your primary focus is maximizing production throughput: The rapid melting cycles and continuous 24-hour operational capability of an IGBT furnace are its most compelling features.

- If your primary focus is reducing long-term operational costs: The exceptional energy efficiency and low maintenance requirements will deliver a significant return on investment over the life of the equipment.

- If your primary focus is process precision and quality control: The digital control offered by IGBT technology provides the repeatable, highly accurate melting profiles necessary for high-quality casting and metallurgy.

Ultimately, adopting an IGBT-based system is an investment in process control, efficiency, and future-ready manufacturing.

Summary Table:

| Key Feature | Benefit |

|---|---|

| IGBT Digital Control | Precise temperature management & repeatable melt cycles |

| High Energy Efficiency | Significant reduction in electricity costs |

| Rapid Melting Speed | Increased production throughput |

| Solid-State Reliability | Low maintenance & minimal downtime |

| Clean Power Operation | Prevents electrical interference with other equipment |

Ready to upgrade your metal melting process with precision and efficiency?

Leveraging exceptional R&D and in-house manufacturing, KINTEK provides diverse laboratories and foundries with advanced high-temperature furnace solutions. Our product line, including IGBT Induction Melting Furnaces, Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, is complemented by our strong deep customization capability to precisely meet your unique production requirements.

Contact KINTEL today to discuss how our IGBT technology can deliver faster melting, lower energy costs, and greater reliability for your operation.

Visual Guide

Related Products

- Vacuum Induction Melting Furnace

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

- 1200℃ Controlled Inert Nitrogen Atmosphere Furnace

- Split Multi Heating Zone Rotary Tube Furnace Rotating Tube Furnace

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

People Also Ask

- What are the core functions of the High Vacuum Induction Melting (VIM) furnace? Optimize DD5 Superalloy Purification

- How does vacuum melting technology contribute to sustainability? Boost Durability and Recycling Efficiency

- How has vacuum smelting impacted the development of superalloys? Unlock Higher Strength and Purity

- Why is a Vacuum Induction Melting (VIM) furnace essential? Unlock Purity for Aerospace and Semiconductors

- What role does a vacuum induction melting furnace play in Fe-5%Mn-C alloys? Ensure Chemical Integrity and High Purity