In short, a medium frequency (MF) induction furnace can process an extensive range of metals. Its capabilities include common ferrous metals like carbon steel and stainless steel, non-ferrous metals such as aluminum and copper, and even high-value precious metals like gold and silver. The technology's flexibility makes it a cornerstone of modern foundries and metalworking operations.

The core principle of induction heating is not about compatibility with specific metals, but about a metal's ability to conduct electricity. Any electrically conductive metal can be melted; the key variables are the efficiency and speed at which this occurs, which are determined by the furnace's design and the metal's specific properties.

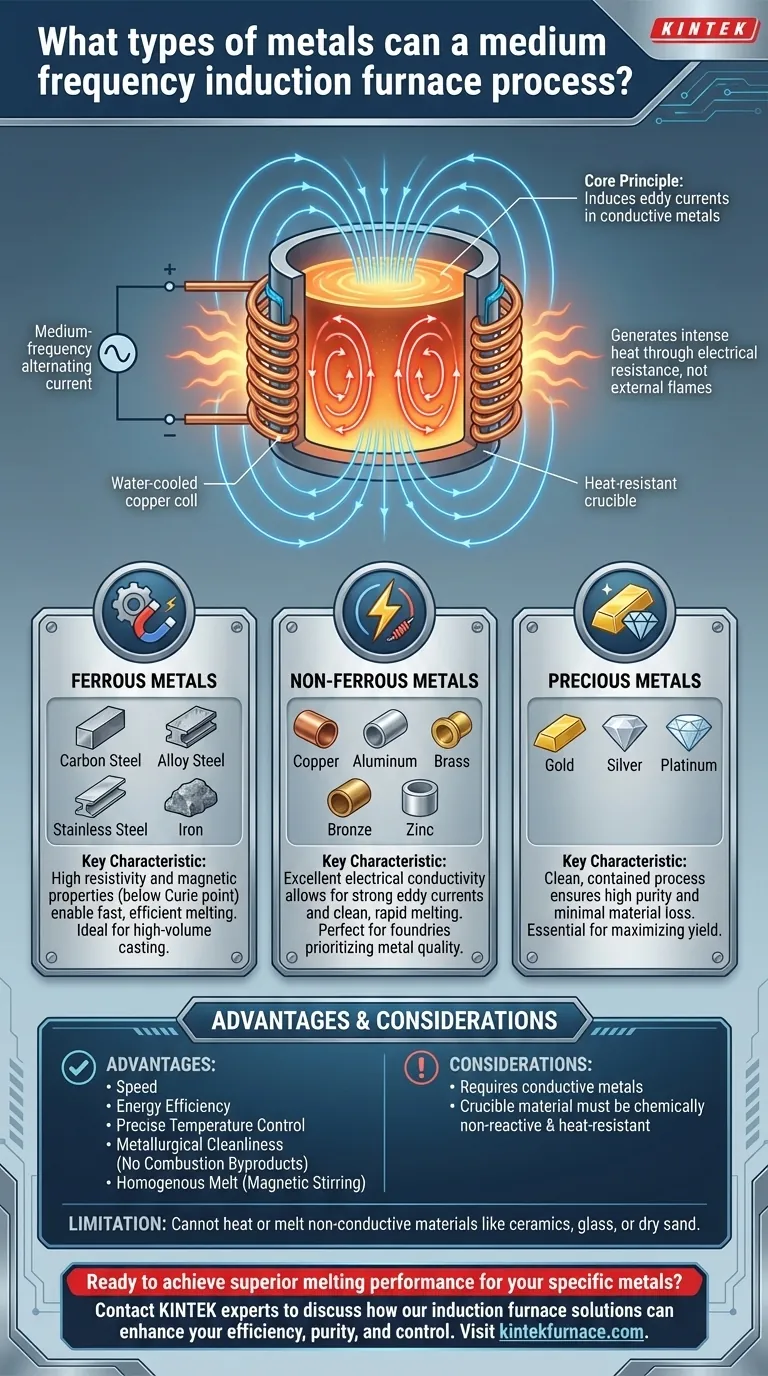

How Induction Melting Works: The Principle of Resistance

An MF induction furnace does not use external flames or heating elements to melt metal. Instead, it turns the metal itself into the source of the heat. This process is clean, contained, and exceptionally fast.

Creating a Magnetic Field

The furnace's core component is a water-cooled copper coil. When a medium-frequency alternating current is passed through this coil, it generates a powerful and rapidly changing magnetic field in the space within the coil.

Inducing Electrical Currents

This magnetic field penetrates the metal charge (the scrap or ingot) placed inside a crucible within the coil. According to the principles of electromagnetism, the fluctuating field induces powerful electrical currents, known as eddy currents, to flow directly within the metal.

Generating Heat from Within

As these eddy currents swirl through the metal, they encounter the material's natural electrical resistance. This resistance converts the electrical energy into intense heat, raising the metal's temperature rapidly and uniformly until it melts. The process is analogous to how a wire can get hot if too much current passes through it.

A Breakdown of Compatible Metals

The furnace's operating principle makes it compatible with nearly any metal that conducts electricity. The primary differences lie in the efficiency and the specific setup required for each material type.

Ferrous Metals: The Primary Use Case

This is the most common application for MF induction furnaces. This category includes:

- Carbon Steel

- Alloy Steel

- Stainless Steel

- Various types of Iron

These materials respond exceptionally well to induction due to their magnetic properties (when below the Curie temperature) and electrical resistivity, leading to very fast and efficient melting.

Non-Ferrous Metals: Expanding Capability

Induction furnaces are also highly effective for melting non-ferrous metals, even though they are not magnetic. Their electrical conductivity is the key property. Common examples include:

- Copper

- Aluminum

- Brass

- Bronze

- Zinc

The high conductivity of metals like copper and aluminum allows for strong eddy currents to be induced, resulting in clean and rapid melting.

Precious Metals: Precision and Purity

The clean, self-contained nature of induction melting is a major advantage for high-value metals where any contamination or material loss is costly. These include:

- Gold

- Silver

- Platinum Group Metals

The process introduces minimal impurities, as there are no byproducts of combustion, ensuring high metallurgical quality.

Understanding the Trade-offs and Considerations

While versatile, MF induction furnaces are not a universal solution. Understanding their operational advantages and limitations is critical for proper application.

The Advantage: Speed and Control

Because the heat is generated within the metal, melting is extremely fast and energy-efficient compared to methods that must first heat a chamber. Temperature can be controlled with high precision, which is vital for creating specific alloys.

The Advantage: Metallurgical Cleanliness

With no burning fuel, there are no contaminants like sulfur or carbon from the heat source introduced into the melt. This results in a cleaner final product. Furthermore, the stirring action caused by the magnetic fields helps create a homogenous, well-mixed molten bath.

The Consideration: The Crucible

The molten metal is held in a non-conductive, heat-resistant container called a crucible. The crucible material (often a ceramic or graphite composite) must be carefully selected to withstand the target temperature and to be chemically non-reactive with the specific metal being melted.

The Limitation: Non-Conductive Materials

The primary limitation of this technology is that it cannot heat or melt non-conductive materials. Materials like ceramics, glass, or dry sand will not heat up in an induction furnace because they do not allow eddy currents to flow.

Making the Right Choice for Your Goal

The decision to use an MF induction furnace should be based on your specific operational priorities, whether they are volume, purity, or flexibility.

- If your primary focus is high-volume steel and iron casting: MF induction is an industry standard, prized for its speed, energy efficiency, and precise control over alloy chemistry.

- If your primary focus is casting non-ferrous metals like aluminum or brass: The technology provides exceptionally clean and rapid melting, making it ideal for foundries that prioritize metal quality and fast turnaround times.

- If your primary focus is working with precious metals: The contained, non-contaminating nature of induction melting is essential for maximizing your yield and maintaining the absolute purity of the final product.

Ultimately, the furnace's suitability depends less on if it can melt a specific metal and more on the quality, efficiency, and production goals of your operation.

Summary Table:

| Metal Type | Examples | Key Characteristics for Induction Melting |

|---|---|---|

| Ferrous Metals | Carbon Steel, Stainless Steel, Iron | High electrical resistivity and magnetic properties (below Curie point) enable fast, efficient melting. |

| Non-Ferrous Metals | Aluminum, Copper, Brass, Zinc | Excellent electrical conductivity allows for strong eddy currents and clean, rapid melting. |

| Precious Metals | Gold, Silver, Platinum | Clean, contained process ensures high purity and minimal material loss. |

Ready to achieve superior melting performance for your specific metals?

At KINTEK, we leverage our exceptional R&D and in-house manufacturing to provide advanced high-temperature furnace solutions tailored to your unique needs. Whether you are processing high-volume steel, non-ferrous alloys, or high-purity precious metals, our product line—including Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems—is backed by deep customization capabilities to precisely meet your experimental and production requirements.

Contact our experts today to discuss how our induction furnace solutions can enhance your efficiency, purity, and control.

Visual Guide

Related Products

- Vacuum Induction Melting Furnace

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

People Also Ask

- Why is a Vacuum Induction Melting (VIM) furnace essential? Unlock Purity for Aerospace and Semiconductors

- What are the common applications of Vacuum Induction Melting? Essential for High-Performance Metals and Alloys

- What is the purpose of vacuum melting, casting and re-melting equipment? Achieve High-Purity Metals for Critical Applications

- What role does a vacuum induction melting furnace play in Fe-5%Mn-C alloys? Ensure Chemical Integrity and High Purity

- What are some common applications of vacuum induction melting and casting (VIM&C)? Essential for Aerospace, Medical, and Nuclear Industries