The primary function of a water-cooled copper crucible in the preparation of Sm-Co-Fe ternary alloys is to guarantee the material's purity by preventing chemical reactions between the melt and the container. By actively circulating cooling water, the crucible dissipates heat rapidly enough to create a physical barrier between the molten alloy and the crucible walls.

The water-cooled crucible utilizes a "cold skull" mechanism to contain the melt. By freezing the outer layer of the alloy, it ensures the molten material is held within a shell of its own composition, completely eliminating contamination from the crucible itself.

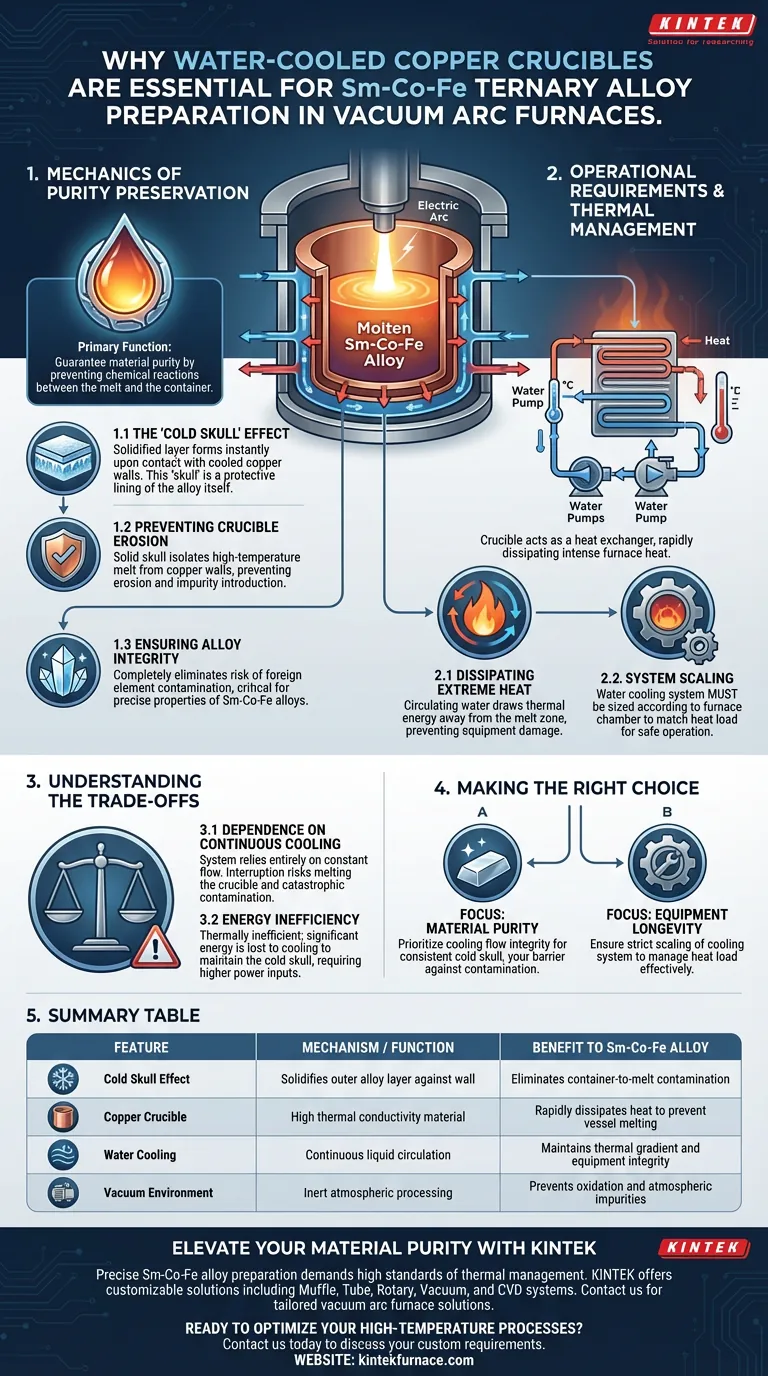

The Mechanics of Purity Preservation

The "Cold Shell" Effect

The most critical role of the water-cooled system is the creation of a solidified layer, often referred to as a "cold shell" or "skull." Because the copper is actively cooled, the molten Sm-Co-Fe alloy instantly solidifies upon contact with the crucible walls.

Preventing Crucible Erosion

This solid skull acts as a protective lining. It ensures that the high-temperature melt is contained by the solidified alloy rather than the copper crucible itself. This prevents the reactive melt from eroding the crucible material, which is the primary source of impurities in high-temperature processing.

Ensuring Alloy Integrity

By maintaining this separation, the process eliminates the risk of introducing foreign elements into the mixture. This is essential for Sm-Co-Fe alloys, where high purity is required to achieve precise material properties.

Operational Requirements and Thermal Management

Dissipating Extreme Heat

A vacuum arc furnace generates intense heat to melt the alloy components. The copper crucible serves as a heat exchanger, using circulating water to draw thermal energy away from the melt zone to prevent the equipment from melting or deforming.

System Scaling

For this mechanism to work, the cooling system cannot be arbitrary. As noted in operational standards, the water cooling system must be sized according to the furnace chamber. This ensures the cooling capacity matches the heat load, allowing for the normal, safe operation of the vacuum furnace.

Understanding the Trade-offs

Dependence on Continuous Cooling

The system relies entirely on the continuous flow of water. Any interruption or insufficiency in the cooling system risks melting the copper crucible, which would lead to catastrophic contamination of the alloy and potential damage to the furnace.

Energy Inefficiency

While excellent for purity, this method is thermally inefficient. A significant amount of energy used to melt the alloy is immediately lost to the cooling water to maintain the solid skull, requiring higher power inputs compared to insulated crucible methods.

Making the Right Choice for Your Project

To ensure the successful preparation of your Sm-Co-Fe alloys, consider the following based on your specific goals:

- If your primary focus is material purity: Prioritize the integrity of the water-cooling flow to maintain a consistent "cold skull," as this is your only barrier against contamination.

- If your primary focus is equipment longevity: Ensure the water cooling system is strictly scaled to the size of your furnace chamber to manage the heat load effectively.

By utilizing the thermal gradient of a water-cooled copper crucible, you transform the container from a potential contaminant into a neutral vessel.

Summary Table:

| Feature | Mechanism/Function | Benefit to Sm-Co-Fe Alloy |

|---|---|---|

| Cold Skull Effect | Solidifies outer alloy layer against wall | Eliminates container-to-melt contamination |

| Copper Crucible | High thermal conductivity material | Rapidly dissipates heat to prevent vessel melting |

| Water Cooling | Continuous liquid circulation | Maintains thermal gradient and equipment integrity |

| Vacuum Environment | Inert atmospheric processing | Prevents oxidation and atmospheric impurities |

Elevate Your Material Purity with KINTEK

Precise Sm-Co-Fe alloy preparation demands the highest standards of thermal management and contamination control. At KINTEK, we understand that the integrity of your research depends on the quality of your equipment.

Backed by expert R&D and manufacturing, KINTEK offers Muffle, Tube, Rotary, Vacuum, and CVD systems, alongside specialized lab high-temp furnaces that are fully customizable for your unique metallurgical needs. Whether you require advanced water-cooled crucible integration or tailored vacuum arc furnace solutions, our team is ready to deliver the performance your laboratory deserves.

Ready to optimize your high-temperature processes? Contact us today to discuss your custom furnace requirements with our specialists.

Visual Guide

References

- Zhi Hong Zhu, Jiashuo Zhang. Effect of Fe Content on Phase Behavior of Sm–Co–Fe Alloys During Solidification and Aging. DOI: 10.3390/ma18081854

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

- Laboratory Vacuum Tilt Rotary Tube Furnace Rotating Tube Furnace

- Ultra High Vacuum Stainless Steel KF ISO CF Flange Pipe Straight Pipe Tee Cross Fitting

- Vacuum Hot Press Furnace Machine Heated Vacuum Press Tube Furnace

People Also Ask

- What role does a vacuum arc melting furnace with a non-consumable electrode play? Key to CuAlMn Shape Memory Alloys

- What are some common applications of vacuum induction melting and casting (VIM&C)? Essential for Aerospace, Medical, and Nuclear Industries

- Why is a Vacuum Induction Melting furnace (VIM) used for Cu-Zn-Al-Sn alloys? Achieve Precision Composition Control

- Why are multiple repeated melting cycles necessary in the production of Ni-Ti-Hf-La alloys? Ensuring Homogenization

- How does high thermal efficiency benefit induction furnaces? Unlock Major Cost Savings & Quality

- How does precise temperature control in a high-temp induction furnace influence AL-2024 melting for composites?

- What auxiliary role does a Ni/Al2O3 catalyst play in induction heating? Enhancing Ammonia Decomposition Uniformity

- What role does electromagnetic stirring play in vacuum induction melting? Enhance Alloy Quality and Efficiency