At a fundamental level, induction furnaces offer a vast capacity range, from systems melting less than one kilogram for laboratories to industrial giants holding over 100 metric tons of molten metal. While smaller furnaces under a few hundred kilograms are common in research and specialty casting, the technology scales significantly for high-volume production in iron, steel, and non-ferrous foundries.

The question of an induction furnace's capacity is answered by its design type and intended application. Coreless furnaces provide batch-based flexibility across all scales, while large channel furnaces are engineered for continuous, high-volume melting and holding of a single alloy.

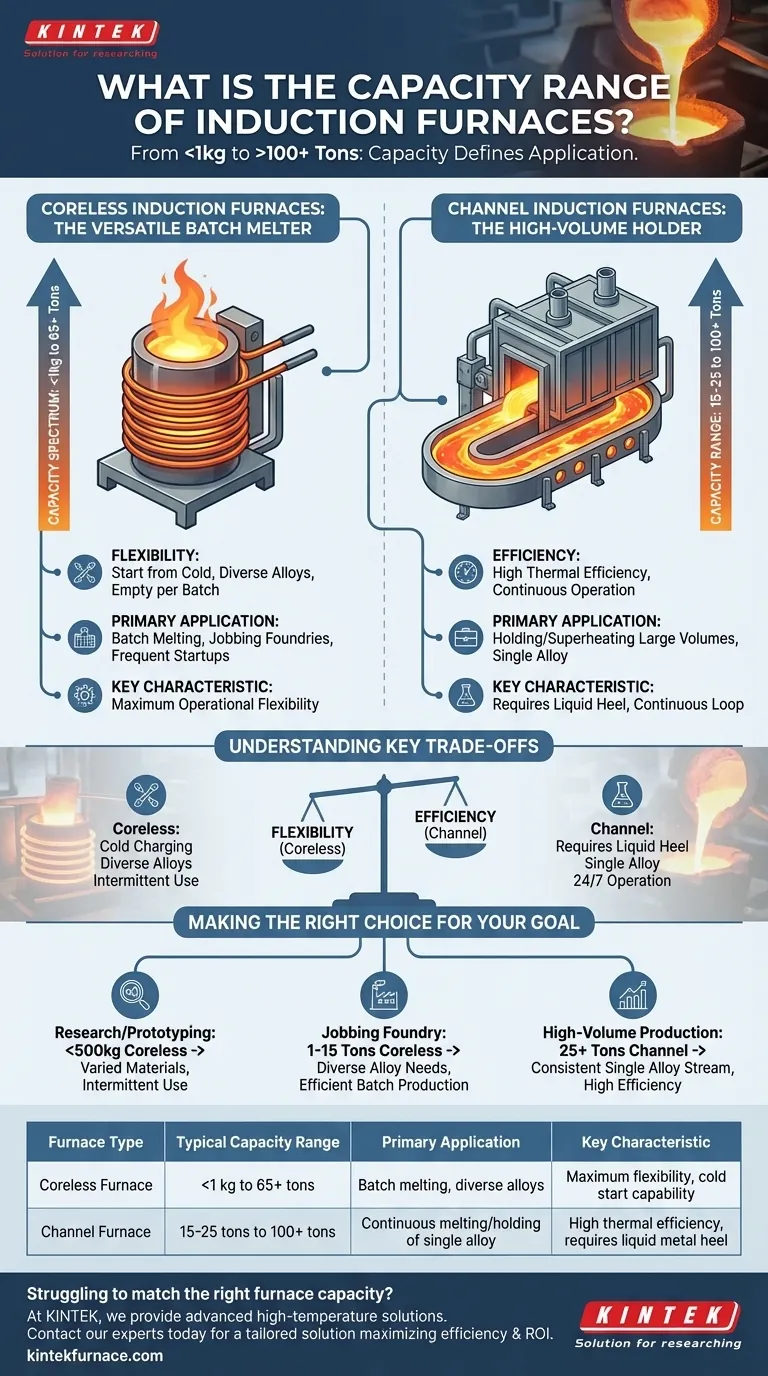

Two Core Designs Dictate Capacity

The capacity of an induction furnace is not a single, linear scale. It is fundamentally tied to one of two core technologies: the coreless furnace or the channel furnace. Each is optimized for a different operational purpose, which in turn defines its typical size and application.

Coreless Induction Furnaces: The Versatile Batch Melter

A coreless furnace functions like a large, water-cooled crucible surrounded by an induction coil. The alternating magnetic field directly heats the metal charge inside.

This simple, robust design makes it incredibly versatile. Coreless furnaces span the entire capacity spectrum, from small tabletop units melting a few kilograms of precious metal to massive systems capable of melting over 65 tons of iron per batch.

Their primary advantage is flexibility. They can be started from cold, emptied completely after each melt (or "heat"), and used for a wide variety of different metals and alloys, making them the standard for most foundries.

Channel Induction Furnaces: The High-Volume Holder

A channel furnace operates more like a transformer. The "channel" is a loop of molten metal that passes through an induction coil, acting as the secondary circuit of the transformer. This loop continuously heats the main bath of metal in the furnace.

Because they require a continuous loop of liquid metal to operate, channel furnaces are not designed for small-scale or batch operations. They are typically used for holding, superheating, and duplexing large volumes of a single metal.

Their capacities are generally large, often starting around 15-25 tons and extending well beyond 100 tons. They are prized for their high thermal efficiency in continuous production environments, such as large automotive foundries or pipe-spinning plants.

Understanding the Key Trade-offs

Choosing a furnace is not just about size; it's about matching the technology's operational model to your production needs. The differences between coreless and channel designs create critical trade-offs.

Flexibility vs. Efficiency

Coreless furnaces offer maximum operational flexibility. You can change alloys from one batch to the next and shut the furnace down completely when not in use.

Channel furnaces offer maximum thermal efficiency. However, this comes at the cost of flexibility. They must maintain a molten "heel" of metal at all times and are therefore best suited to melting the same alloy continuously for long campaigns.

Cold Charging vs. Liquid Heel

The ability of a coreless furnace to melt a charge from solid, cold material is a key advantage for operations with intermittent schedules.

A channel furnace cannot be started from cold. It must first be filled with liquid metal to complete the induction circuit. This makes it impractical for anything other than 24/7 or semi-continuous operations.

Application Suitability

The coreless design is ideal for jobbing foundries that produce castings from many different alloys, or for any facility that requires frequent startups and shutdowns.

The channel design excels in large, integrated facilities where it can act as a high-efficiency holding vessel, ensuring a constant supply of molten metal at a precise temperature for an automated production line.

Making the Right Choice for Your Goal

To select the right furnace, first define your operational priorities. Your production model—batch versus continuous—will guide you to the correct technology and capacity.

- If your primary focus is research, prototyping, or small-scale art casting: A coreless furnace under 500 kg provides the ideal flexibility for varied materials and intermittent use.

- If your primary focus is a jobbing foundry with diverse alloy needs: A small to mid-size coreless furnace (1 to 15 tons) is the industry standard for efficient batch production.

- If your primary focus is high-volume, continuous production of a single alloy: A large channel furnace (25+ tons) provides the highest efficiency for holding and supplying a consistent metal stream.

Ultimately, understanding your operational flow is the key to selecting the correct induction furnace capacity and type for your goal.

Summary Table:

| Furnace Type | Typical Capacity Range | Primary Application | Key Characteristic |

|---|---|---|---|

| Coreless Furnace | <1 kg to 65+ tons | Batch melting, diverse alloys | Maximum flexibility, cold start capability |

| Channel Furnace | 15-25 tons to 100+ tons | Continuous melting/holding of single alloy | High thermal efficiency, requires liquid metal heel |

Struggling to match the right furnace capacity to your production goals?

At KINTEK, we leverage our exceptional R&D and in-house manufacturing to provide diverse laboratories and foundries with advanced high-temperature furnace solutions. Whether you need a small-scale coreless furnace for R&D or a large channel furnace for high-volume production, our product line—including Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems—is complemented by strong deep customization capabilities to precisely meet your unique melting requirements.

Contact our experts today to discuss your application and get a tailored solution that maximizes your efficiency and ROI.

Visual Guide

Related Products

- Vacuum Induction Melting Furnace

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

- Laboratory Muffle Oven Furnace with Bottom Lifting

People Also Ask

- Why is a Vacuum Induction Melting (VIM) furnace essential? Unlock Purity for Aerospace and Semiconductors

- What are some common applications of vacuum induction melting and casting (VIM&C)? Essential for Aerospace, Medical, and Nuclear Industries

- How does the Vacuum Induction Melting (VIM) process work? Achieve Superior Metal Purity and Control

- What role does a vacuum induction melting furnace play in Fe-5%Mn-C alloys? Ensure Chemical Integrity and High Purity

- How does vacuum melting technology contribute to sustainability? Boost Durability and Recycling Efficiency