At their core, induction furnaces provide significant environmental benefits by eliminating direct on-site pollution and operating with exceptionally high energy efficiency. Unlike traditional fuel-fired furnaces, they do not burn fossil fuels, which means they release no harmful gases, dust, or soot into the immediate atmosphere, creating a cleaner and safer workplace.

The primary environmental advantage of an induction furnace is its ability to decouple the heating process from combustion. This shift not only eliminates local emissions but also leverages the electrical grid's efficiency, making it a strategic tool for reducing a facility's total carbon footprint.

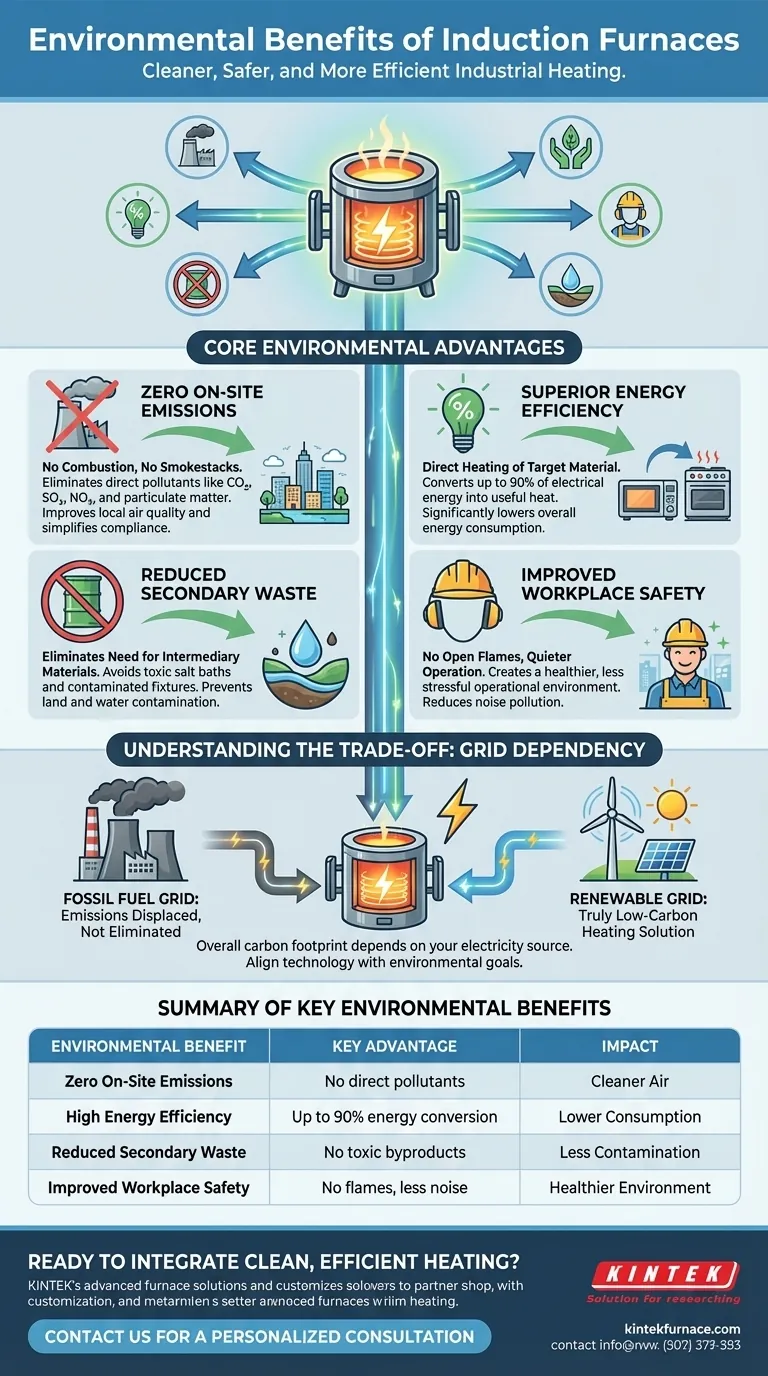

The Core Environmental Advantages

An induction furnace's design fundamentally changes how it interacts with the environment compared to traditional combustion-based methods. The benefits extend beyond just air quality.

Eliminating Direct Site Emissions

Induction furnaces do not have smokestacks because they do not burn fuel. This complete absence of on-site combustion means they produce zero direct pollutants like CO₂, SOx, NOx, or particulate matter.

This directly improves local air quality, benefiting both employees and the surrounding community. It also simplifies compliance with increasingly strict environmental regulations.

Superior Energy Efficiency

Induction heating is a remarkably efficient process, capable of converting up to 90% of its electrical energy into useful heat within the target material.

Think of it like a microwave oven heating food directly, rather than a conventional oven that must first heat all the air inside it. Induction generates heat inside the conductive material, minimizing wasted energy that would otherwise radiate into the environment. This high efficiency directly translates to lower overall energy consumption.

Reducing Secondary Waste Streams

Traditional heat-treating and melting processes often create significant secondary waste. This includes toxic salt baths, contaminated jigs and fixtures, and other hazardous byproducts that require special, costly disposal.

Induction technology eliminates the need for these intermediary materials. By heating the part directly, it avoids land and water contamination associated with disposing of toxic chemical waste.

Improving the Immediate Work Environment

Beyond emissions, induction furnaces create a healthier and safer workplace. They operate without open flames or massive volumes of hot exhaust gas.

Furthermore, they are significantly quieter than many combustion furnaces, reducing noise pollution and creating a less stressful operational environment for workers.

Understanding the Trade-offs: Grid Dependency

While induction furnaces have no direct emissions, their overall environmental impact is tied to the source of their electricity. This is the most critical trade-off to understand.

The Source of Your Power Matters

An induction furnace's carbon footprint is a reflection of the electrical grid it's connected to. If the grid is powered primarily by fossil fuels like coal or natural gas, the CO₂ emissions are simply displaced from the factory to the power plant.

However, when paired with a grid rich in renewables (solar, wind, hydro) or nuclear power, the induction furnace becomes a truly low-carbon heating solution.

Not a Universal Solution

Induction heating works by inducing an electric current in a conductive material. This means it is highly effective for metals but is not suitable for non-conductive materials like ceramics or certain composites without a secondary conductive vessel (a susceptor).

Aligning Technology with Your Environmental Goals

Choosing an induction furnace is a strategic decision that aligns with specific environmental and operational objectives.

- If your primary focus is meeting local air quality regulations and improving worker safety: The complete elimination of on-site emissions and a quieter, cooler work environment is the key benefit.

- If your primary focus is achieving corporate carbon neutrality or ESG targets: The high energy efficiency, combined with sourcing renewable electricity, provides a clear and measurable path to reducing your carbon footprint.

- If your primary focus is minimizing overall waste and long-term liability: The reduction of secondary waste streams, particularly toxic salts and contaminated materials, is the most compelling advantage.

Ultimately, adopting induction furnace technology is a definitive step toward more precise, efficient, and environmentally responsible industrial heating.

Summary Table:

| Environmental Benefit | Key Advantage |

|---|---|

| Zero On-Site Emissions | No direct CO₂, SOx, NOx, or particulate matter released. |

| High Energy Efficiency | Up to 90% of electrical energy converted directly into heat. |

| Reduced Secondary Waste | Eliminates need for toxic salt baths and contaminated fixtures. |

| Improved Workplace Safety | No open flames, hot exhaust, and significantly quieter operation. |

Ready to integrate clean, efficient heating into your operations?

Leveraging exceptional R&D and in-house manufacturing, KINTEK provides diverse laboratories and industrial facilities with advanced high-temperature furnace solutions. Our product line, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, is complemented by our strong deep customization capability to precisely meet unique experimental and production requirements.

Contact us today to discuss how our induction furnace technology can help you meet your environmental goals and improve operational efficiency. Get in touch via our contact form for a personalized consultation.

Visual Guide

Related Products

- Vacuum Induction Melting Furnace

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- Laboratory Muffle Oven Furnace with Bottom Lifting

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

People Also Ask

- Why is a Vacuum Induction Melting (VIM) furnace essential? Unlock Purity for Aerospace and Semiconductors

- How does the Vacuum Induction Melting (VIM) process work? Achieve Superior Metal Purity and Control

- How does vacuum melting technology contribute to sustainability? Boost Durability and Recycling Efficiency

- What is the purpose of vacuum melting, casting and re-melting equipment? Achieve High-Purity Metals for Critical Applications

- What role does a vacuum induction melting furnace play in Fe-5%Mn-C alloys? Ensure Chemical Integrity and High Purity