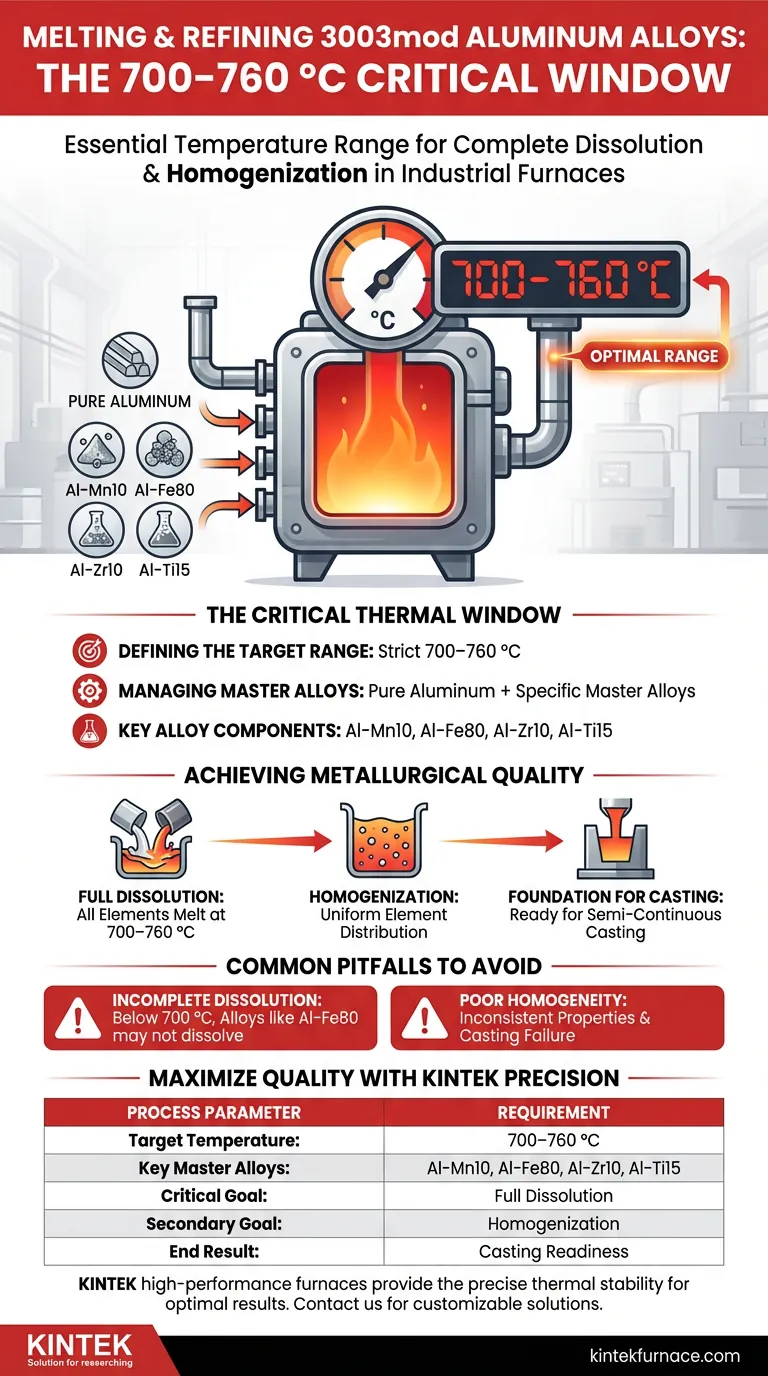

The required temperature range for melting and refining 3003mod aluminum alloys in industrial furnaces is 700–760 °C. This precise thermal window is necessary to process the mixture of pure aluminum and specific master alloys effectively.

Core Takeaway Simply melting the base aluminum is insufficient; you must maintain a temperature of 700–760 °C to ensure the complete dissolution of master alloys like Al-Mn10 and Al-Fe80, creating the homogenized composition required for successful semi-continuous casting.

The Critical Thermal Window

Defining the Target Range

To prepare 3003mod aluminum alloys, industrial furnaces must maintain a strict temperature range of 700–760 °C.

Managing Master Alloys

This high-temperature environment is not just for the base metal. It is specifically designed to accommodate the addition of pure aluminum alongside various master alloys.

Key Alloy Components

The process specifically involves integrating master alloys such as Al-Mn10, Al-Fe80, Al-Zr10, and Al-Ti15. Each of these must be brought to the target temperature to ensure proper interaction with the aluminum base.

Achieving Metallurgical Quality

Full Dissolution

The primary objective of holding the melt between 700–760 °C is to ensure full dissolution of the alloying elements.

Homogenization

Once dissolved, the elements must be uniformly distributed throughout the melt. This specific heat range facilitates the homogenization of the composition, preventing segregation of elements.

Foundation for Casting

This melting and refining phase serves as the critical setup for the next production step. A fully homogenized melt provides the necessary foundation for the semi-continuous casting process.

Common Pitfalls to Avoid

Risk of Incomplete Dissolution

If the furnace temperature falls below the 700 °C threshold, there is a significant risk that the master alloys—particularly those with higher melting points like Al-Fe80—will not fully dissolve.

Consequences of Poor Homogeneity

Failure to maintain this specific high-temperature environment prevents the composition from stabilizing. This leads to inconsistencies in the material properties that will carry over into the casting phase.

Making the Right Choice for Your Goal

To ensure the structural integrity and quality of your 3003mod aluminum alloy, apply the following parameters:

- If your primary focus is Compositional Accuracy: Ensure the furnace reaches at least 700 °C to guarantee the complete dissolution of complex master alloys like Al-Fe80 and Al-Ti15.

- If your primary focus is Process Stability: Maintain the upper limit near 760 °C to facilitate rapid homogenization before the semi-continuous casting stage begins.

Strict adherence to the 700–760 °C range is the only way to transform raw ingredients into a high-quality, cast-ready 3003mod alloy.

Summary Table:

| Process Parameter | Requirement | Purpose |

|---|---|---|

| Target Temperature | 700–760 °C | Optimal melting & refining window |

| Key Master Alloys | Al-Mn10, Al-Fe80, Al-Zr10, Al-Ti15 | Strengthening & grain refinement |

| Critical Goal | Full Dissolution | Preventing segregation of high-melt elements |

| Secondary Goal | Homogenization | Ensuring uniform chemical composition |

| End Result | Casting Readiness | Foundation for semi-continuous casting |

Maximize Your Alloy Quality with KINTEK Precision

Achieving the perfect 700–760 °C thermal window is essential for the structural integrity of 3003mod aluminum. Backed by expert R&D and manufacturing, KINTEK offers high-performance Muffle, Tube, Rotary, and Vacuum systems, all customizable to meet your unique metallurgical needs.

Our advanced high-temperature furnaces provide the precise thermal stability required for the full dissolution and homogenization of complex master alloys. Don't compromise on material consistency—Contact KINTEK today to discover how our expert heating solutions can optimize your industrial casting process.

Visual Guide

References

- Wenhui Zheng, Wei Xu. High-Temperature Mechanical Properties and Microstructure of Ultrathin 3003mod Aluminum Alloy Fins. DOI: 10.3390/met14020142

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- 1400℃ Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

People Also Ask

- What is the primary function of a vacuum arc furnace in the production of Ti-6Al-7Nb alloys? Ensure Peak Material Purity

- How does an induction furnace affect copper grain size? Optimize Microstructure with Rapid Heating

- What finishing processes follow metal casting in induction furnaces? Achieve Precision and Efficiency in Metalworking

- Why is a high-vacuum induction melting furnace required for near alpha-titanium alloys? Ensure Purity & Performance

- What role do induction melting furnaces play in metal recycling? Boost Efficiency and Quality in Scrap Processing

- What are the applications of IGBT Vacuum Induction Melting Furnaces? Essential for High-Purity Metal Production

- What industries commonly use induction-heated vacuum furnaces? Unlock High-Purity, High-Performance Material Processing

- What are the technical advantages of using an induction annealing furnace? Boost Graphite Purity and Throughput