To be direct, induction-heated vacuum furnaces are a cornerstone technology in industries where material failure is not an option. The aerospace, medical, automotive, and energy sectors are the primary users, relying on these furnaces to create high-purity, high-performance components that must withstand extreme conditions without contamination.

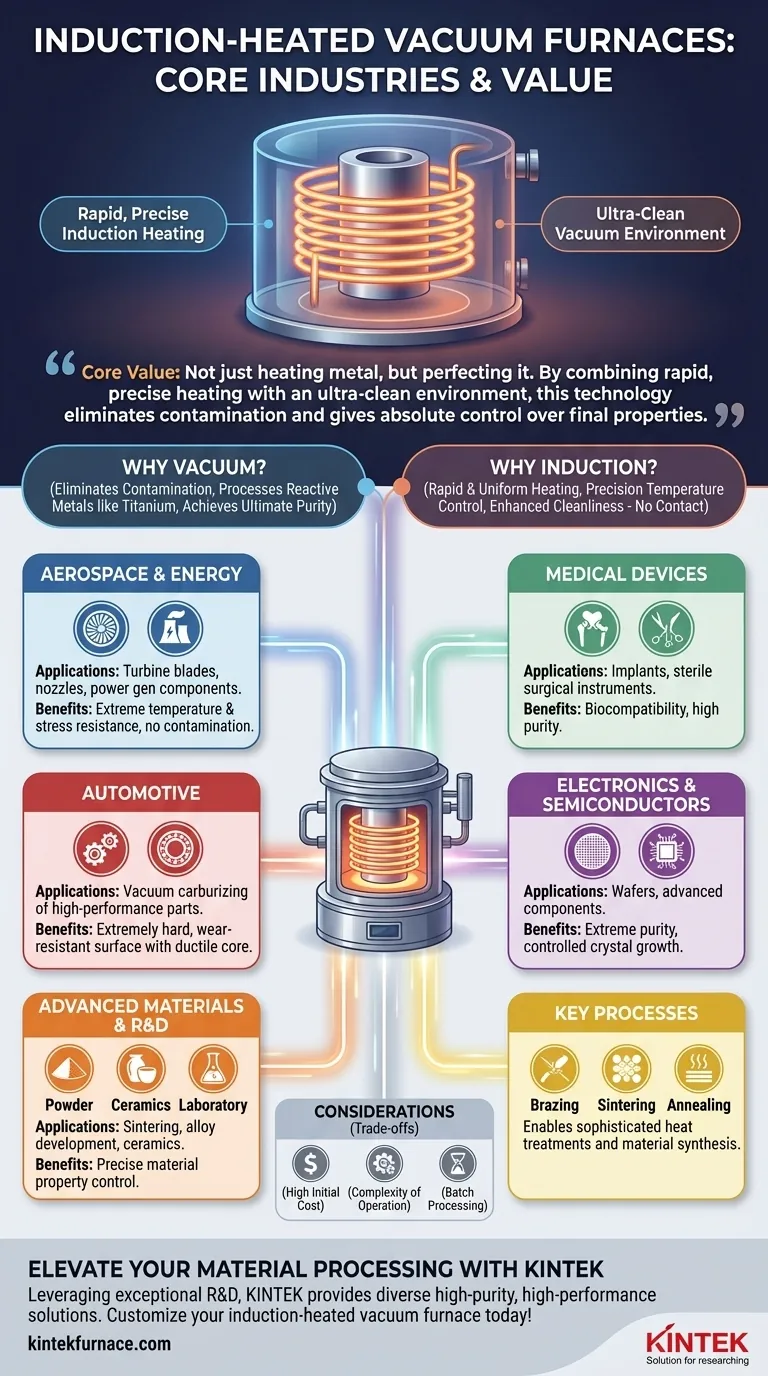

The core value of an induction-heated vacuum furnace is not just heating metal, but perfecting it. By combining rapid, precise heating (induction) with an ultra-clean environment (vacuum), this technology eliminates contamination and gives manufacturers absolute control over a material's final properties.

Why a Vacuum Environment is Non-Negotiable

The "vacuum" in a vacuum furnace is the key to achieving superior material properties. At the high temperatures required for heat treatment and melting, most metals are highly reactive.

Eliminating Contamination and Oxidation

In a normal atmosphere, hot metal instantly reacts with oxygen, nitrogen, and water vapor. This creates oxides and other impurities on and within the material, compromising its strength, fatigue life, and overall integrity.

A vacuum removes these reactive gases, ensuring the material's surface and internal structure remain pristine.

Processing Reactive and Advanced Metals

Materials like titanium, zirconium, and various superalloys are essential for aerospace and medical applications. These metals are so reactive that processing them in anything other than a high-vacuum environment is impossible if you want to retain their desired properties.

Achieving Ultimate Purity

For applications in semiconductors, electronics, and research, even trace amounts of impurities can render a component useless. Vacuum induction furnaces are used to refine high-purity metals and create alloys with precisely controlled chemical compositions, a task unachievable with other methods.

The Role of Induction Heating

While the vacuum provides a clean slate, induction is the tool that precisely shapes the material's final character. It is a non-contact method that uses an electromagnetic field to generate heat directly within the metal itself.

Rapid and Uniform Heating

Induction heats the material from the inside out, resulting in exceptionally fast and uniform temperature distribution. This consistency is critical for ensuring that an entire component, whether a small medical implant or a large turbine blade, has the same structural properties throughout.

Precision Temperature Control

Induction heating systems allow for highly programmable and repeatable heating and cooling cycles. This precision is essential for sophisticated heat treatments like vacuum brazing, sintering, annealing, and hardening, where specific temperature profiles create specific material characteristics.

Enhanced Cleanliness

Because the heating is accomplished via a magnetic field, the heat source never touches the material. This eliminates the risk of contamination that can occur with conventional furnaces, where particles from electric heating elements can flake off and embed in the component.

Key Industrial Applications and Processes

The combination of a clean vacuum and precise induction heating enables manufacturing processes that are critical to several high-tech industries.

Aerospace and Energy

Components like jet engine turbine blades, nozzles, and power generation equipment are produced in these furnaces. The process ensures they can withstand extreme temperatures and mechanical stress without failing.

Medical Devices

The biocompatibility of medical implants, such as artificial hips and dental roots, depends on absolute purity. Vacuum furnaces create strong, sterile, and contamination-free surgical instruments and implants.

Automotive

High-performance automotive parts like gears, fuel injectors, and bearings undergo a process called vacuum carburizing (a type of case hardening). This creates an extremely hard, wear-resistant surface while maintaining a tougher, more ductile core.

Electronics and Semiconductors

The manufacturing of semiconductor wafers and other advanced electronic components relies on the extreme purity and controlled crystal growth that only a vacuum environment can provide.

Advanced Materials and R&D

For metallurgists and material scientists, these furnaces are indispensable tools. They are used for sintering powdered metals into solid high-strength parts, producing advanced ceramics, and developing next-generation alloys.

Understanding the Trade-offs

While powerful, this technology is not the solution for every heating application. Understanding its limitations is key to using it effectively.

High Initial Cost

Vacuum induction furnace systems represent a significant capital investment compared to traditional atmosphere furnaces. The cost includes the furnace itself, robust vacuum pumps, advanced power supplies, and sophisticated control systems.

Complexity of Operation

These are not "set and forget" machines. They require skilled operators to manage the complex interplay between the vacuum, temperature, and power controls. Maintenance is also more intensive due to the nature of high-vacuum systems.

Batch Processing

Most vacuum furnaces operate in batches. While ideal for high-value components, this process can be slower and less efficient for the mass production of simple, low-cost parts compared to continuous, non-vacuum furnace lines.

Making the Right Choice for Your Goal

Deciding on a thermal process requires matching the technology to the required outcome and budget.

- If your primary focus is extreme purity and performance: Induction vacuum furnaces are the definitive standard for reactive metals and mission-critical components where material integrity is paramount.

- If your primary focus is high-volume heat treatment: A continuous atmosphere furnace might be more cost-effective, provided some level of surface oxidation is acceptable for the application.

- If your primary focus is simple surface hardening: Traditional induction hardening in open air can be sufficient and more economical for less demanding parts that do not require a pristine, oxide-free surface.

Ultimately, selecting an induction vacuum furnace is a strategic decision to prioritize material perfection over production volume and initial cost.

Summary Table:

| Industry | Key Applications | Benefits |

|---|---|---|

| Aerospace | Turbine blades, nozzles | Extreme temperature resistance, no contamination |

| Medical | Implants, surgical tools | Biocompatibility, high purity |

| Automotive | Gears, bearings via vacuum carburizing | Wear resistance, ductile core |

| Energy | Power generation components | High performance under stress |

| Electronics | Semiconductors, advanced components | Controlled crystal growth, ultimate purity |

| R&D | Sintering, alloy development | Precise material property control |

Elevate your material processing with KINTEK's advanced high-temperature furnace solutions! Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with induction-heated vacuum furnaces, including Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures we precisely meet your unique experimental needs for high-purity, high-performance results in industries like aerospace, medical, and automotive. Contact us today to discuss how our tailored solutions can optimize your processes and drive innovation!

Visual Guide

Related Products

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

- Laboratory Muffle Oven Furnace with Bottom Lifting

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

People Also Ask

- How does a vacuum furnace prevent heat transfer and contamination? Achieve Ultimate Material Purity

- Where are vacuum furnaces used? Critical Applications in Aerospace, Medical, and Electronics

- Why does heating steel rod bundles in a vacuum furnace eliminate heat transfer paths? Enhance Surface Integrity Today

- What is a vacuum furnace used for? Achieve Purity and Precision in High-Temp Processing

- What does a vacuum furnace do? Achieve Superior Material Processing in a Pure Environment