In short, an IGBT Vacuum Induction Melting (VIM) furnace is used across a range of high-technology industries for melting, refining, and casting materials where extreme purity and precise chemical composition are non-negotiable. Key applications are found in aerospace, material science, automotive, and semiconductor manufacturing for producing high-performance superalloys, reactive metals, and other advanced materials.

The true value of a VIM furnace is not just its ability to melt metal, but its power to do so within a controlled vacuum. This environment is the key to preventing contamination and achieving a level of material purity and structural integrity that is impossible with conventional melting techniques.

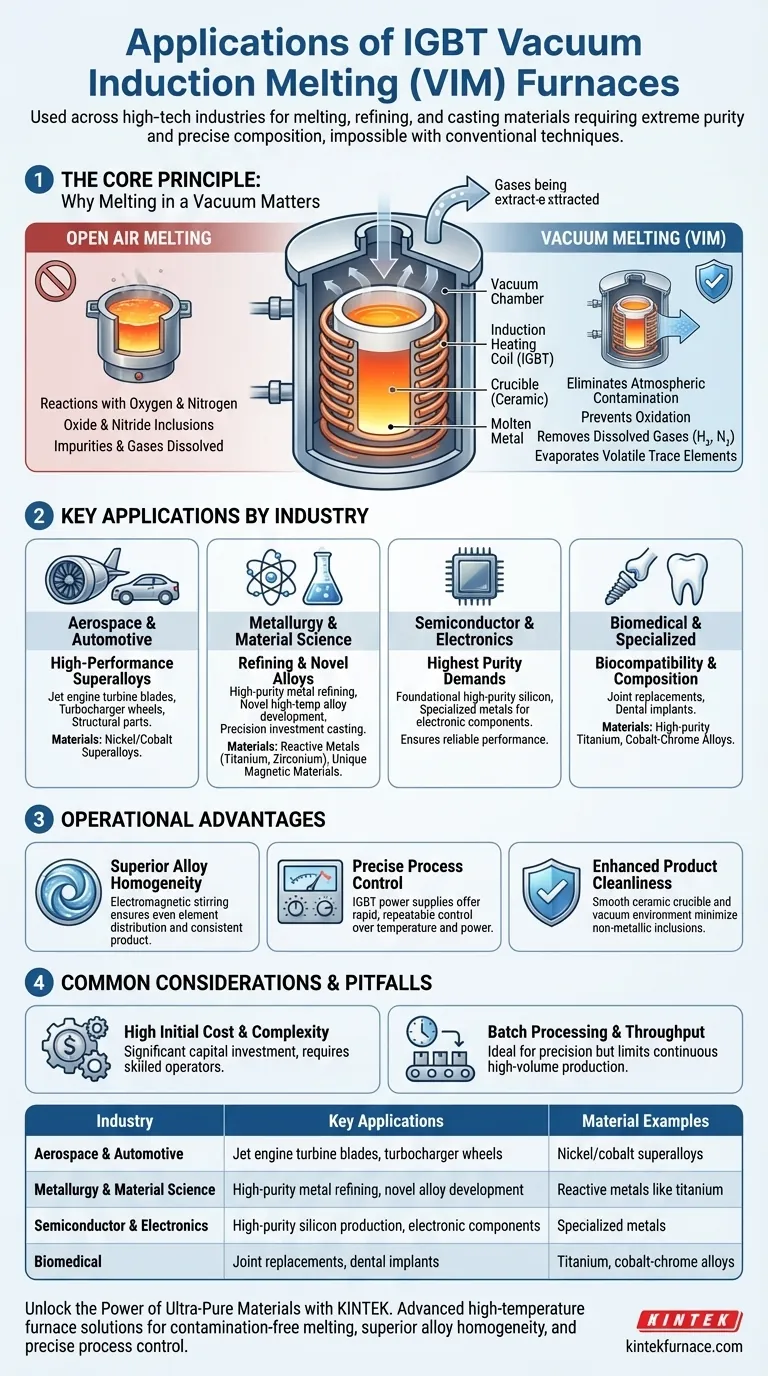

The Core Principle: Why Melting in a Vacuum Matters

The defining feature of a VIM furnace is its vacuum chamber. This isn't just an add-on; it is fundamental to the results it produces. Operating in a vacuum fundamentally changes the melting process, providing two critical advantages.

Eliminating Atmospheric Contamination

When metals are melted in open air, they react with oxygen and nitrogen. This reaction forms unwanted oxide and nitride inclusions, which act as impurities that can compromise the final material's strength and performance.

By removing the air, the vacuum environment prevents this oxidation from ever occurring, resulting in a cleaner, higher-quality melt.

Removing Harmful Impurities

The vacuum actively pulls dissolved gases, like hydrogen and nitrogen, out of the molten metal. It also helps evaporate and remove volatile trace elements (like lead or bismuth) that have a lower boiling point.

This degassing and purification process is critical for producing materials with superior mechanical properties, such as improved fatigue life and ductility.

Enabling Reactive Metal Processing

Metals like titanium and zirconium are highly reactive and will readily bond with oxygen and nitrogen at high temperatures. A VIM furnace provides the inert environment necessary to melt these materials without creating brittle, contaminated alloys.

Key Applications by Industry

The ability to create ultra-pure, precisely-controlled alloys makes VIM furnaces indispensable in sectors where material failure is not an option.

Aerospace and Automotive

These industries rely on VIM furnaces to produce high-performance superalloys (often nickel or cobalt-based) for critical components.

Applications include casting jet engine turbine blades, turbocharger wheels, and other structural parts that must withstand extreme temperatures, pressures, and mechanical stress.

Metallurgy and Material Science

VIM furnaces are a cornerstone of modern metallurgy. They are used for refining high-purity metals, developing novel high-temperature alloys, and producing materials with unique magnetic properties.

They are also used for precision investment casting of complex parts, such as high-performance valves for extreme industrial environments.

Semiconductor and Electronics

The semiconductor industry demands materials of the highest possible purity. VIM furnaces are used to produce the foundational high-purity silicon and other specialized metals required for electronic components, ensuring reliable performance.

Biomedical and Specialized Fields

The biocompatibility of medical implants is directly tied to their purity and precise composition. VIM furnaces are used to create the high-purity titanium and cobalt-chrome alloys used in joint replacements and dental implants, minimizing the risk of adverse reactions in the body.

Understanding the Operational Advantages

Beyond the vacuum, several other features of an IGBT VIM furnace contribute to its utility in these demanding applications.

Superior Alloy Homogeneity

The induction heating process creates a natural electromagnetic stirring effect within the molten bath. This ensures all alloying elements are distributed perfectly evenly, preventing element segregation and guaranteeing a consistent, homogenous final product.

Precise Process Control

Modern IGBT (Insulated-Gate Bipolar Transistor) power supplies offer precise and rapid control over the melting temperature and power input. This, combined with automation, allows for highly repeatable processes, which is crucial for quality control in certified applications.

Enhanced Product Cleanliness

The process uses a smooth, non-reactive ceramic crucible. This, combined with the vacuum environment, drastically reduces the chance of non-metallic inclusions from the crucible contaminating the melt, leading to a cleaner final cast.

Common Pitfalls and Considerations

While powerful, VIM furnaces are a specialized tool and not a universal solution for all melting needs.

High Initial Cost and Complexity

VIM furnaces are sophisticated systems that represent a significant capital investment. They also require skilled operators who are trained in both metallurgy and vacuum technology.

Batch Processing Throughput

These furnaces operate on a batch-by-batch basis. This is ideal for precision and control but can be a limitation for industries requiring the continuous, high-volume production of more common metals.

Over-specification for Simpler Metals

For standard alloys and metals where extreme purity is not a requirement (e.g., common steel or aluminum casting), a VIM furnace is often over-specified. A traditional, more cost-effective air-melt induction or arc furnace is better suited for those tasks.

Making the Right Choice for Your Goal

To determine if a VIM furnace is the correct tool, you must first define your material requirements.

- If your primary focus is producing certified superalloys for critical applications (aerospace, energy): A VIM furnace is essential for achieving the required purity, strength, and fatigue resistance.

- If your primary focus is developing novel materials or conducting advanced metallurgical research: The precise control and ultra-clean environment of a VIM furnace are indispensable for obtaining valid, repeatable results.

- If your primary focus is high-volume casting of standard, non-reactive metals: A more conventional and cost-effective air-melt induction furnace is almost always the more appropriate choice.

Ultimately, the decision to use a VIM furnace is driven by an uncompromising need for material purity and performance.

Summary Table:

| Industry | Key Applications | Material Examples |

|---|---|---|

| Aerospace & Automotive | Jet engine turbine blades, turbocharger wheels | Nickel/cobalt superalloys |

| Metallurgy & Material Science | High-purity metal refining, novel alloy development | Reactive metals like titanium |

| Semiconductor & Electronics | High-purity silicon production, electronic components | Specialized metals |

| Biomedical | Joint replacements, dental implants | Titanium, cobalt-chrome alloys |

Unlock the Power of Ultra-Pure Materials with KINTEK

Are you in aerospace, automotive, material science, or semiconductor manufacturing and struggling to achieve the extreme purity and precise chemical composition your high-performance alloys demand? KINTEK has the solution. Leveraging exceptional R&D and in-house manufacturing, we provide advanced high-temperature furnace solutions tailored to your unique needs. Our product line, including IGBT Vacuum Induction Melting Furnaces, Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, is complemented by strong deep customization capabilities to precisely meet your experimental and production requirements.

By partnering with KINTEK, you'll benefit from contamination-free melting, superior alloy homogeneity, and precise process control—ensuring your materials meet the highest standards for strength, durability, and performance. Don't let impurities hold back your innovations. Contact us today to discuss how our customized furnace solutions can elevate your lab's efficiency and drive your success in critical applications!

Visual Guide

Related Products

- Vacuum Induction Melting Furnace

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

- Laboratory Muffle Oven Furnace with Bottom Lifting

People Also Ask

- What are the key features and benefits of a Vacuum Induction Melting Furnace? Achieve High-Purity Metal Production

- What are the main industrial applications of vacuum melting furnaces? Achieve Unmatched Material Purity and Performance

- How does vacuum induction melting work? Achieve Ultra-Pure, High-Performance Alloys

- What are the advantages of vacuum induction melting? Achieve Superior Purity for High-Performance Alloys

- What components make up a Vacuum Induction Melting Furnace? Discover the Key Systems for Pure Metal Melting