Induction annealing offers a superior thermal mechanism for graphite purification by utilizing electromagnetic fields to generate heat directly within the processing crucible. This internal heat generation decouples the process from the limitations of external heating elements found in traditional Joule heating, leading to drastically faster processing times and higher energy efficiency.

By shifting the heat source to the graphite crucible itself, induction furnaces can ramp to 2400 °C in less than 15 minutes. This rapid thermal capability drives production throughput while consistently achieving purity levels exceeding 99.8%.

The Physics of Internal Heat Generation

Electromagnetic Induction vs. Joule Heating

In traditional Joule heating, heat is generated by passing current through a resistive element and then transferring that heat to the material.

Induction annealing fundamentally changes this dynamic. It utilizes electromagnetic induction to cause the graphite crucible to generate heat internally. This eliminates the thermal lag associated with transferring heat from an external element to the payload.

Superior Heat Transfer Rates

Because the heat is generated directly within the crucible walls surrounding the graphite, the system achieves heat transfer rates several times higher than traditional methods.

This direct energy coupling ensures that energy is used to heat the target material immediately, rather than heating the surrounding furnace structure first.

Operational Performance Metrics

Unprecedented Heating Speed

The most distinct advantage of this technology is the heating rate. The system can bring natural graphite to a processing temperature of 2400 °C in under 15 minutes.

This rapid ramping is critical for high-volume industrial applications where cycle time dictates profitability.

Energy Efficiency and Throughput

The efficiency of induction annealing directly correlates to reduced operational costs. By minimizing heat loss and accelerating the process, energy consumption per unit of graphite is significantly lowered.

Simultaneously, the reduced cycle times allow for a substantial increase in production throughput compared to the slower thermal cycles of Joule heating.

Achieving High-Grade Purity

The Thermal Threshold

High-temperature purification relies on volatizing impurities to separate them from the graphite.

The induction method consistently maintains the extreme temperatures required for this phase.

Purity Outcomes

The precise control and high temperatures of induction annealing result in a superior end product.

Operators can expect to achieve high purity levels exceeding 99.8%, making the output suitable for demanding high-tech applications.

Understanding the Operational Trade-offs

Managing Rapid Thermal Transitions

The capability to reach 2400 °C in under 15 minutes places significant thermal stress on the system components.

While this speed is an advantage for throughput, it requires robust process monitoring to ensure the graphite crucible can withstand the rapid expansion and internal energy generation without structural failure.

Dependency on Crucible Interaction

The efficiency of this process is entirely dependent on the electromagnetic coupling with the graphite crucible.

Unlike Joule heating, which pushes heat at a target, induction requires the crucible to act as the heat engine; therefore, the consistency of the crucible material is critical to maintaining the stated heat transfer rates.

Making the Right Choice for Your Goal

If you are evaluating purification technologies, align your choice with your specific operational KPIs:

- If your primary focus is maximizing production volume: Choose induction annealing to leverage the 15-minute heating cycle and drastically increase daily throughput.

- If your primary focus is reducing operating costs: Select induction annealing to utilize the superior energy efficiency inherent in internal heat generation.

- If your primary focus is product quality: Rely on induction processing to consistently achieve the >99.8% purity levels required for battery-grade materials.

Induction annealing transforms graphite purification from a slow thermal soak into a rapid, high-precision industrial process.

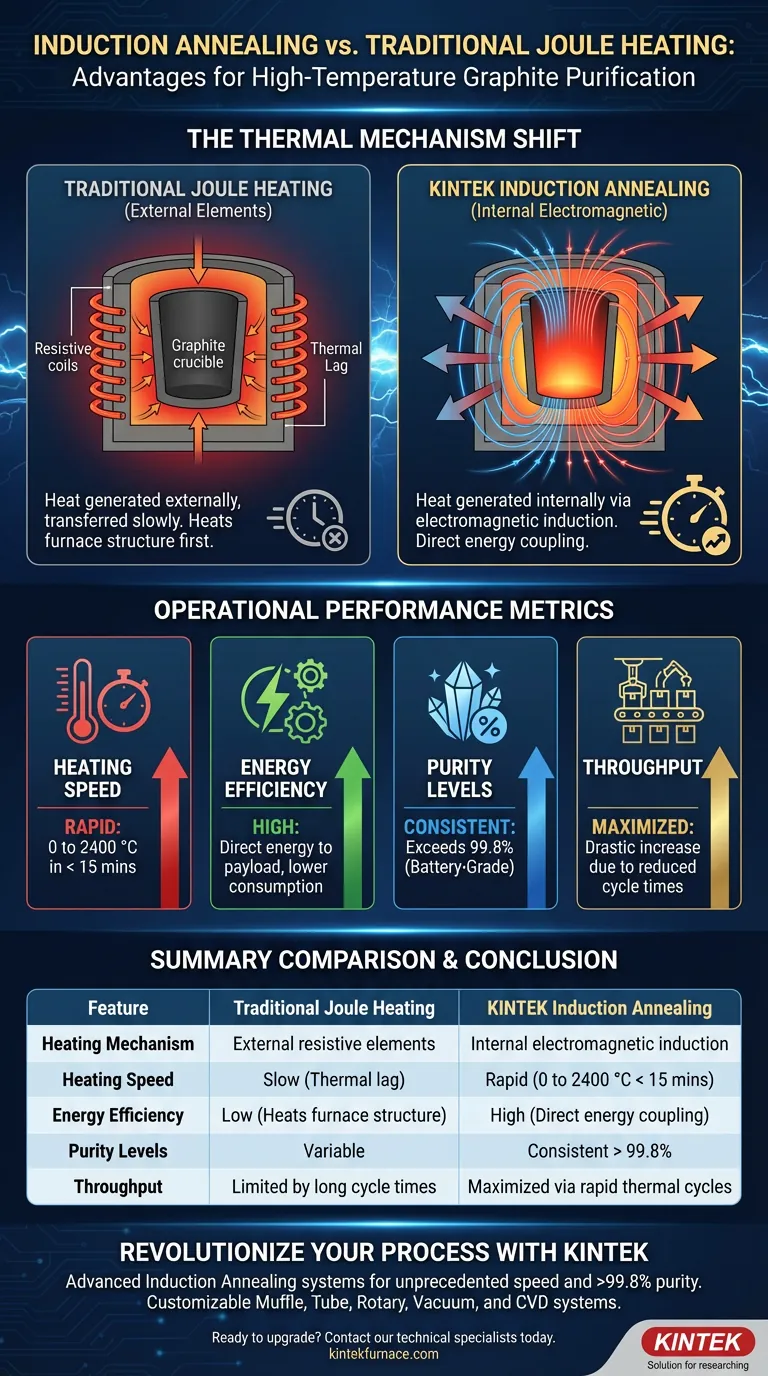

Summary Table:

| Feature | Traditional Joule Heating | KINTEK Induction Annealing |

|---|---|---|

| Heating Mechanism | External resistive elements | Internal electromagnetic induction |

| Heating Speed | Slow (Thermal lag) | Rapid (0 to 2400 °C < 15 mins) |

| Energy Efficiency | Low (Heats furnace structure) | High (Direct energy coupling) |

| Purity Levels | Variable | Consistent > 99.8% |

| Throughput | Limited by long cycle times | Maximized via rapid thermal cycles |

Revolutionize Your Graphite Purification with KINTEK

Don't let slow thermal cycles bottleneck your production. KINTEK’s advanced Induction Annealing systems are engineered to deliver unprecedented heating speeds and high-grade purity exceeding 99.8%.

Backed by expert R&D and world-class manufacturing, we offer a full range of Muffle, Tube, Rotary, Vacuum, and CVD systems, all fully customizable to meet your specific lab or industrial requirements. Whether you are scaling battery-grade material production or optimizing lab research, KINTEK provides the high-temperature precision you need.

Ready to upgrade your efficiency? Contact our technical specialists today to find the perfect thermal solution for your unique needs.

Visual Guide

References

- Anna Lähde, Jorma Jokiniemi. Effect of high temperature thermal treatment on the electrochemical performance of natural flake graphite. DOI: 10.1557/s43578-024-01282-z

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1400℃ Muffle Oven Furnace for Laboratory

- Vacuum Heat Treat Sintering Furnace Molybdenum Wire Vacuum Sintering Furnace

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

People Also Ask

- What is inductive stirring and how does it work? Master Molten Metal Mixing for Superior Alloys

- What are the advantages of using intermediate frequency smelting technology? Achieve Rapid, Uniform Melting for Superior Quality

- What safety benefits does induction heating provide in the workplace? Achieve a Flameless, Contained Heating Process

- How is the semi-levitation effect generated in induction cold crucible melting? Unlock Ultra-Pure Alloy Synthesis

- What auxiliary role does a Ni/Al2O3 catalyst play in induction heating? Enhancing Ammonia Decomposition Uniformity

- What role does a vacuum induction melting furnace play in Fe-5%Mn-C alloys? Ensure Chemical Integrity and High Purity

- What is the function of a vacuum induction melting furnace for AlCoCrFeNi2.1? Mastering High-Entropy Alloy Production

- What types of materials can be smelted in an induction furnace? Master the Art of Clean, Efficient Metal Melting