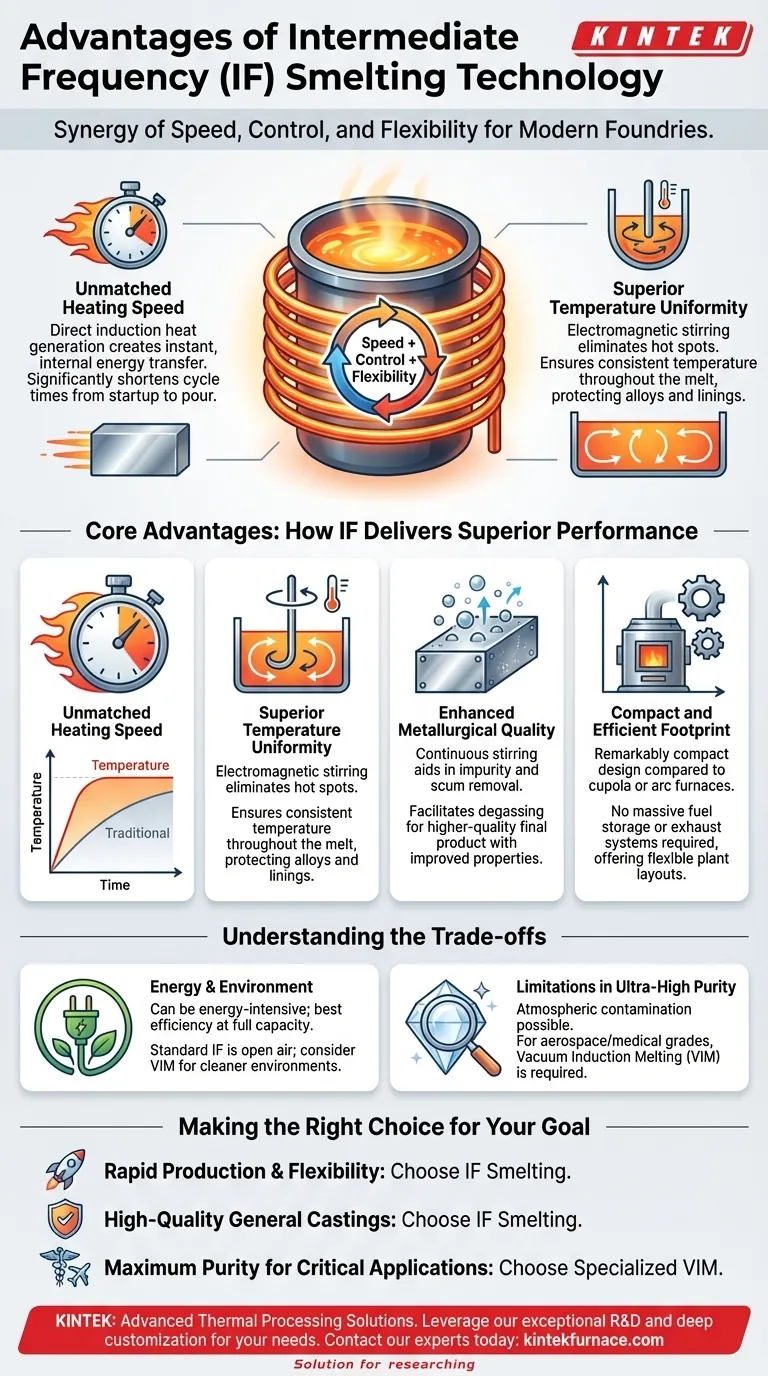

At its core, intermediate frequency (IF) smelting technology offers a powerful combination of speed, metallurgical control, and operational flexibility. Its primary advantages are the ability to rapidly and uniformly heat metal, which enhances the removal of impurities, all while using equipment that is significantly more compact than traditional furnaces.

The central advantage of intermediate frequency smelting is not just one feature, but the synergy of its core capabilities. It provides rapid, controlled, and clean melting in a small footprint, making it a highly versatile tool for modern foundries.

How IF Technology Delivers Superior Performance

To understand the benefits, it's essential to grasp the core principle. IF smelting uses electromagnetic induction to generate heat directly within the metal itself, rather than relying on external burners or heating elements. This fundamental difference drives its key advantages.

Unmatched Heating Speed

The process generates heat instantly and internally through eddy currents. This direct energy transfer is far more efficient and faster than conventional methods that must first heat the furnace walls and then transfer that heat to the metal charge via conduction and radiation.

This rapid temperature increase significantly shortens cycle times from startup to pour.

Superior Temperature Uniformity

The electromagnetic field creates a natural stirring action within the molten metal bath. This constant motion ensures the temperature remains remarkably uniform throughout the melt, eliminating hot spots that can damage alloys and degrade furnace linings.

This uniformity is critical for achieving consistent material properties.

Enhanced Metallurgical Quality

The stirring effect and even heating directly contribute to cleaner metal. The gentle, continuous movement helps non-metallic inclusions and scum float to the surface, where they can be easily removed.

This process facilitates degassing and reduces impurities, leading to a higher-quality final product with improved mechanical properties.

Compact and Efficient Footprint

Compared to older technologies like cupola or arc furnaces, IF induction furnaces are remarkably compact and lightweight. They do not require massive fuel storage, exhaust flues, or electrode handling systems.

This makes them ideal for facilities with limited space and allows for more flexible plant layouts.

Understanding the Trade-offs

No technology is a universal solution. While IF smelting is highly effective, it's important to recognize its operational context and limitations, especially when compared to more specialized variants.

Energy and Environmental Considerations

While fast, the process can be energy-intensive. Its efficiency is highest when operating near full capacity.

Furthermore, standard atmospheric IF smelting does not inherently offer the environmental or workplace improvements of a closed system. Technologies like vacuum induction smelting provide a cleaner operating environment and can offer higher energy efficiency.

Limitations in Ultra-High Purity Metals

For the most demanding applications, such as aerospace or medical-grade alloys, standard IF smelting may not be sufficient. The process occurs in open air, allowing for potential atmospheric contamination.

In these cases, Vacuum Induction Melting (VIM), a specialized form of induction smelting, is required. It performs the melting inside a vacuum, providing superior control over gas content and preventing oxidation to achieve the lowest possible levels of impurities.

Making the Right Choice for Your Goal

Selecting the correct smelting technology depends entirely on your specific production requirements and quality targets.

- If your primary focus is rapid production and operational flexibility: IF smelting is an exceptional choice due to its fast startup, quick melting cycles, and compact size.

- If your primary focus is high-quality general-purpose castings: The inherent stirring action and uniform heating of IF technology provide excellent impurity removal for a wide range of ferrous and non-ferrous alloys.

- If your primary focus is maximum purity for critical applications: You must look to specialized variants like Vacuum Induction Melting (VIM) to achieve the necessary metallurgical control.

Ultimately, choosing the right induction technology is about matching the tool precisely to your metallurgical objective.

Summary Table:

| Advantage | Key Benefit |

|---|---|

| Heating Speed | Rapid, direct energy transfer shortens cycle times. |

| Temperature Uniformity | Electromagnetic stirring eliminates hot spots. |

| Metallurgical Quality | Improves impurity removal and degassing. |

| Footprint | Compact and flexible design saves space. |

Ready to enhance your foundry's efficiency and product quality?

At KINTEK, we leverage our exceptional R&D and in-house manufacturing to provide advanced thermal processing solutions. Whether your goal is rapid production of general-purpose castings or achieving maximum purity for critical applications, our product line—including specialized induction furnaces—is complemented by strong deep customization capabilities to meet your unique requirements.

Contact our experts today to discuss how our high-temperature furnace solutions can be tailored for your intermediate frequency smelting needs.

Visual Guide

Related Products

- Vacuum Induction Melting Furnace

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

- Split Multi Heating Zone Rotary Tube Furnace Rotating Tube Furnace

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

People Also Ask

- What are the core functions of the High Vacuum Induction Melting (VIM) furnace? Optimize DD5 Superalloy Purification

- What is the purpose of vacuum melting, casting and re-melting equipment? Achieve High-Purity Metals for Critical Applications

- How does the Vacuum Induction Melting (VIM) process work? Achieve Superior Metal Purity and Control

- How does vacuum melting technology contribute to sustainability? Boost Durability and Recycling Efficiency

- Why is a Vacuum Induction Melting (VIM) furnace essential? Unlock Purity for Aerospace and Semiconductors