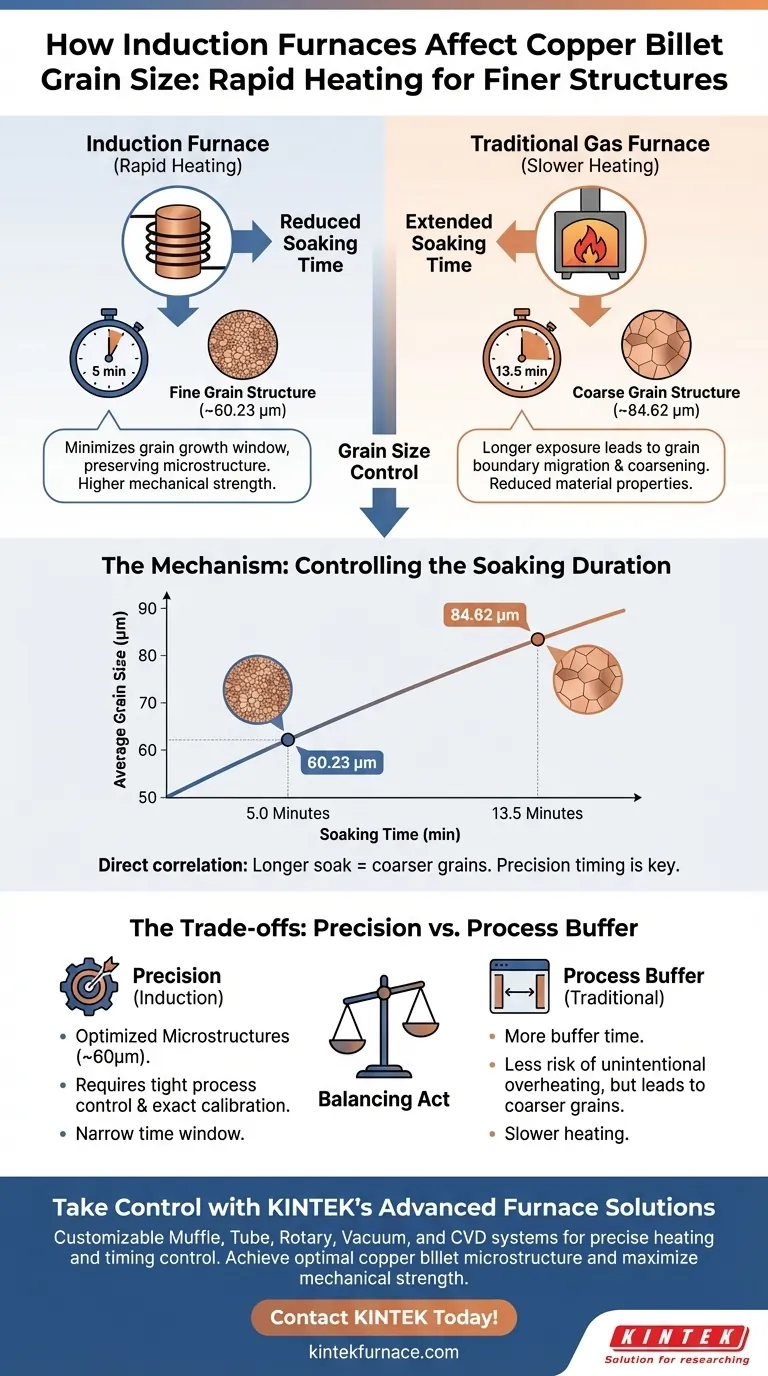

Induction furnaces significantly influence grain size through rapid heating and precise time control. By enabling shorter soaking times compared to traditional gas furnaces, induction heating minimizes the window for grain growth. Specifically, reducing the soaking duration allows the copper billet to retain a finer microstructure, whereas extended exposure to high temperatures invariably leads to grain coarsening.

The rapid heating capability of an induction furnace allows for reduced soaking times, which is the primary factor in preserving fine grain structures in copper billets. Controlling this duration is essential for determining the mechanical properties of the final extruded product.

The Mechanism of Grain Control

Rapid Heating vs. Traditional Methods

Induction furnaces offer a distinct advantage over traditional gas furnaces by generating heat directly within the metal. This allows for rapid heating and precise temperature regulation.

Because the target temperature is reached more quickly, the copper billet spends less total time in the critical grain-growth temperature range.

The Correlation Between Soaking Time and Grain Size

The duration a billet remains at temperature, known as the soaking time, is directly linked to the final grain size.

The relationship is linear: as soaking time increases, grain boundaries migrate and grains merge, resulting in a coarser structure. Controlling this variable is the most effective way to dictate the microstructure of the mother tube.

Data-Driven Evidence

Impact of Short Soaking Durations

Minimizing the soaking time is the key to achieving a fine grain structure.

According to specific processing data, reducing the soaking time in an induction furnace to 5 minutes results in a significantly finer grain size. Under these conditions, the grain size in the mother tube is measured at approximately 60.23 µm.

Consequences of Extended Soaking

When the process is prolonged, the microstructure degrades.

Extending the soaking time to 13.5 minutes allows for substantial grain growth. Data indicates that this longer duration results in grain coarsening up to 84.62 µm, altering the material properties of the alloy.

Understanding the Trade-offs

Precision vs. Process Buffer

While induction heating allows for optimized microstructures, it requires tighter process control than slower heating methods.

Because the window for achieving the optimal 5-minute soak is narrow, operators must ensure precise timing. There is less "buffer" time available compared to slower gas furnaces, meaning unintentional delays can quickly lead to unwanted grain coarsening.

Equipment Calibration

To achieve the specific grain sizes mentioned, the induction furnace requires exact calibration.

Inaccurate temperature sensors or inconsistent power delivery can alter the effective soaking time. This highlights the need for rigorous equipment maintenance to replicate the ~60 µm grain size consistently.

Making the Right Choice for Your Goal

To optimize your copper extrusion process, you must align your furnace settings with your desired material properties.

- If your primary focus is maximizing mechanical strength: Prioritize a short soaking time of approximately 5 minutes to maintain a fine grain size (~60.23 µm).

- If your primary focus is analyzing process defects: Investigate soaking times exceeding 10 minutes, as coarser grains (~84.62 µm) indicate an extended thermal cycle that may be unnecessary.

Mastering the precise timing of your induction furnace is the single most effective lever for controlling copper billet microstructure.

Summary Table:

| Soaking Duration | Average Grain Size (µm) | Microstructure Result | Impact on Material |

|---|---|---|---|

| 5.0 Minutes | ~60.23 µm | Fine Grain | Higher mechanical strength |

| 13.5 Minutes | ~84.62 µm | Coarse Grain | Reduced mechanical properties |

| Rapid Heating | Minimal Growth | Controlled | Optimized for extrusion |

| Extended Heating | Significant Growth | Degraded | Unnecessary thermal cycle |

Precision Heating for Superior Material Properties

Take control of your copper extrusion quality with KINTEK’s advanced induction and high-temperature furnace solutions. Backed by expert R&D and manufacturing, we offer customizable Muffle, Tube, Rotary, Vacuum, and CVD systems designed to provide the rapid heating and precise timing control necessary to prevent grain coarsening and ensure optimal microstructure.

Whether you need to maintain a strict 60µm grain size or require a bespoke system for unique metallurgical needs, KINTEK delivers the equipment and expertise to enhance your lab or production efficiency. Contact KINTEK today to discuss your customization needs!

Visual Guide

References

- Zeynep Sirel, Mehmet Ali Akoy. Influence of Phosphorus Content and Preheating Conditions on Grain Size of Cu-DHP Copper Tubes. DOI: 10.34088/kojose.1475031

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

- 1400℃ Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

People Also Ask

- How does an induction melting furnace work? Achieve Rapid, Clean, and Controlled Metal Melting

- Why is the precise addition of alloying elements in induction furnaces necessary for heavy-section ADI?

- Why are induction furnaces popular for alloy manufacturing? Achieve Superior Alloy Homogeneity and Efficiency

- Why is a vacuum electric arc furnace essential for Ti-Al alloys? Achieve Superior Metal Purity & Homogeneity

- What is the function of a vacuum induction furnace with cold copper crucible in Ti-5Al-2.5Sn alloy preparation?

- Why is temperature control important in induction furnaces? Ensure Consistent Quality and Efficiency

- What are the advantages of Vacuum Induction Melting (VIM)? Achieve Unmatched Metal Purity and Performance

- What are the key industries that utilize vacuum induction melting furnaces? Essential for Aerospace, Medical, and Electronics