At its core, a vacuum induction melting (VIM) furnace is utilized by any industry that demands the absolute highest material purity and performance. The primary users are found in the aerospace, medical, specialty metals, and electronics sectors, where even microscopic impurities can lead to catastrophic failure.

The decision to use a vacuum induction furnace is driven by necessity, not preference. It is the definitive solution for melting reactive metals or producing alloys where atmospheric contamination is unacceptable and material integrity is paramount.

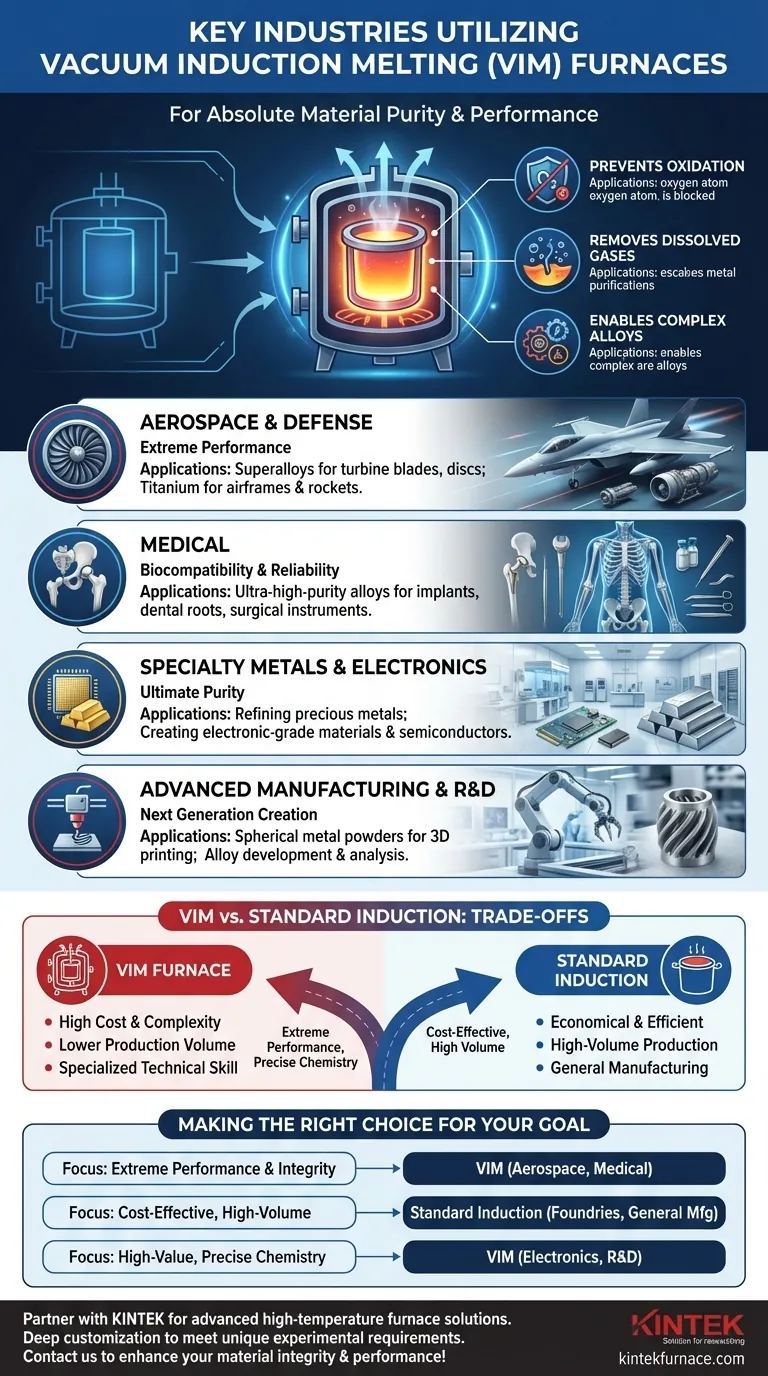

The Core Principle: Why a Vacuum is Essential

Standard furnaces melt metal in the open air. A VIM furnace, however, first creates a vacuum before melting begins. This single difference is what defines its applications.

Preventing Oxidation and Contamination

At high temperatures, most metals—especially reactive ones like titanium and aluminum—readily bond with oxygen and nitrogen in the air. This process, called oxidation, creates impurities that degrade the final material's strength and properties.

A vacuum removes the air, creating a clean, inert environment. This allows for the melting of highly reactive metals without the risk of contamination, ensuring the material remains in its pure form.

Removing Dissolved Gases and Impurities

Molten metal can hold dissolved gases like hydrogen and nitrogen, which become trapped during solidification. These trapped gases create voids and porosity, which are significant weak points in the final component.

The vacuum environment actively pulls these dissolved gases and other volatile, low-vapor-pressure impurities out of the molten bath. This refining process results in a denser, stronger, and more reliable metal.

Enabling Complex and Precise Alloys

VIM furnaces are crucial for producing superalloys, which form the backbone of modern jet engines and turbines. These alloys require the precise addition of reactive elements (like titanium and aluminum) to achieve their extreme heat and stress resistance.

In a standard furnace, these reactive elements would simply burn off and be lost to oxidation. The vacuum protects them, allowing metallurgists to control the final chemistry with incredible accuracy.

Key Industry Applications

The need for this level of purity and control dictates which industries rely on VIM technology.

Aerospace and Defense: The Need for Extreme Performance

This is the largest user of VIM furnaces. They are used to produce nickel-based and cobalt-based superalloys for jet engine turbine blades, discs, and other critical components that operate under immense stress and extreme temperatures.

The technology is also used for ultra-high-strength steels and titanium alloys for missile, rocket, and airframe structures where failure is not an option.

Medical: Ensuring Biocompatibility and Reliability

The human body is an aggressive environment. Medical implants, such as hip joints, dental roots, and surgical instruments, must be completely biocompatible and corrosion-resistant.

VIM is used to produce the ultra-high-purity titanium and cobalt-chrome alloys required for these applications. Any impurity could cause an adverse reaction in the patient or lead to premature failure of the implant.

Specialty Metals and Electronics: The Quest for Ultimate Purity

Industries from electronics to energy rely on materials with specific properties that are ruined by impurities. This includes refining precious metals like gold and platinum to a high degree of purity.

It also involves creating specialized materials for the electronics and semiconductor industries, where even parts-per-billion contamination can alter electrical properties.

Advanced Manufacturing and R&D: Creating the Next Generation

VIM furnaces are used to create the fine, spherical metal powders essential for advanced 3D printing (additive manufacturing). The purity and cleanliness of the powder are critical to the quality of the final printed part.

Furthermore, research and development labs use smaller VIM furnaces to develop, test, and analyze new alloys and material compositions.

Understanding the Trade-offs: VIM vs. Standard Induction

While VIM technology is powerful, it is not the default choice for all metal melting. It is a specialized tool with clear trade-offs.

The Cost and Complexity Factor

VIM furnaces are significantly more expensive to purchase, operate, and maintain than their standard, air-melting counterparts. The complex vacuum pumps, chamber seals, and control systems add layers of cost and require specialized technical skill.

Lower Production Volume

The process of creating a vacuum, melting a batch, and cooling it before breaking the seal is inherently slower than continuous or open-air melting. This makes VIM less suitable for high-volume, commodity metal production.

When Standard Induction is Better

For the vast majority of metal casting, such as iron foundries, aluminum die-casters, and general steel production, a standard induction furnace is the more economical and efficient choice. In these applications, the level of contamination from the air is either acceptable or manageable through other means.

Making the Right Choice for Your Goal

The choice between a VIM furnace and a standard induction furnace is a strategic one, defined entirely by the requirements of the final product.

- If your primary focus is extreme performance and material integrity: VIM is the only option for creating mission-critical superalloys and high-purity reactive metals for aerospace and medical applications.

- If your primary focus is cost-effective, high-volume melting: A standard air-melt induction furnace is the correct tool for most foundries, recycling operations, and general manufacturing.

- If your primary focus is high-value materials with precise chemistry: VIM provides the necessary control and protection for refining precious metals, creating electronic-grade materials, and conducting advanced R&D.

Ultimately, selecting the right melting technology is about matching the tool to the uncompromising demands of the final application.

Summary Table:

| Industry | Key Applications |

|---|---|

| Aerospace & Defense | Jet engine superalloys, titanium alloys for airframes |

| Medical | Biocompatible implants, surgical instruments |

| Specialty Metals & Electronics | High-purity metals, semiconductor materials |

| Advanced Manufacturing & R&D | 3D printing powders, new alloy development |

Leveraging exceptional R&D and in-house manufacturing, KINTEK provides diverse laboratories with advanced high-temperature furnace solutions. Our product line, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, is complemented by our strong deep customization capability to precisely meet unique experimental requirements. If you're in aerospace, medical, or electronics and need reliable, high-purity melting solutions, contact us today to discuss how our expertise can enhance your material integrity and performance!

Visual Guide

Related Products

- Vacuum Induction Melting Furnace

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

People Also Ask

- How does the Vacuum Induction Melting (VIM) process work? Achieve Superior Metal Purity and Control

- What role does a vacuum induction melting furnace play in Fe-5%Mn-C alloys? Ensure Chemical Integrity and High Purity

- What are some common applications of vacuum induction melting and casting (VIM&C)? Essential for Aerospace, Medical, and Nuclear Industries

- What are the core functions of the High Vacuum Induction Melting (VIM) furnace? Optimize DD5 Superalloy Purification

- How does vacuum melting technology contribute to sustainability? Boost Durability and Recycling Efficiency