The primary advantage of Vacuum Induction Melting (VIM) is its unparalleled ability to produce exceptionally pure, clean, and homogenous metals and alloys. By performing the entire melting and refining process under a tightly controlled vacuum, VIM eliminates contamination from atmospheric gases like oxygen and nitrogen. This environment also allows for the removal of unwanted dissolved gases and volatile impurities, resulting in a final product with precise chemical composition and superior material properties.

For high-performance applications where material failure is not an option, conventional melting techniques introduce too many impurities. VIM solves this by creating a controlled 'clean room' for metal, ensuring the final product's chemistry and structure are exactly as designed.

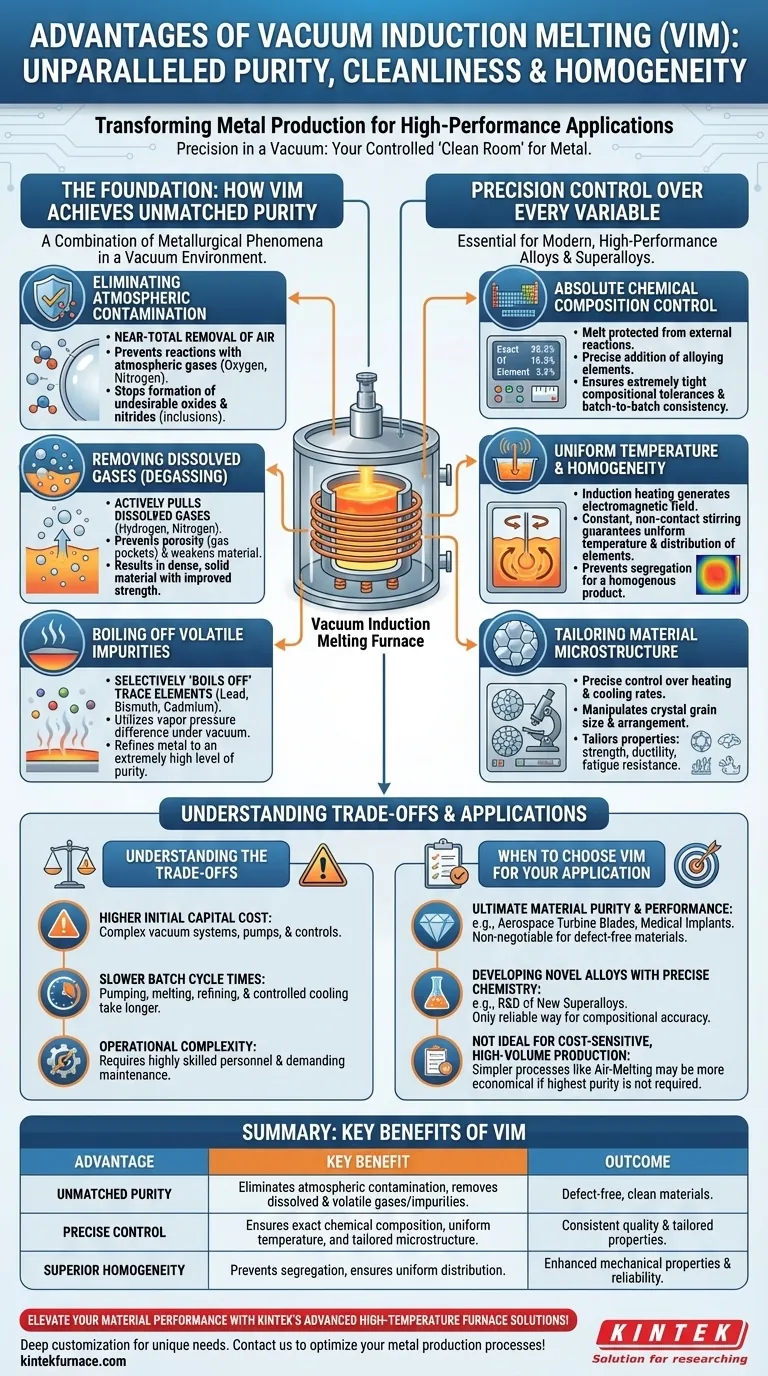

The Foundation: How VIM Achieves Unmatched Purity

The core value of the VIM process is its ability to create an ideal environment for producing clean metal. This is not one single benefit, but a combination of metallurgical phenomena enabled by the vacuum.

Eliminating Atmospheric Contamination

The most significant benefit of the vacuum environment is the near-total removal of air. This prevents reactions between the hot, molten metal and atmospheric gases.

Specifically, it stops the formation of undesirable oxides and nitrides, which can become brittle inclusions in the final material, acting as initiation points for cracks and failures.

Removing Dissolved Gases

Gases like hydrogen and nitrogen can dissolve in molten metal and become trapped as it solidifies. These trapped gas pockets create porosity, a critical defect that severely weakens the material.

The vacuum in a VIM furnace actively pulls these dissolved gases out of the molten bath, a process known as degassing. This results in a dense, solid material with significantly improved mechanical strength.

Boiling Off Volatile Impurities

Many undesirable trace elements (like lead, bismuth, or cadmium) have a higher vapor pressure than the base metal. In simpler terms, they boil at a lower temperature, especially under vacuum.

VIM leverages this principle to selectively "boil off" these volatile impurities, further refining the metal to an extremely high level of purity that is unattainable with air-melting methods.

Precision Control Over Every Variable

Beyond purity, VIM provides a level of process control that is essential for creating modern, high-performance alloys and superalloys.

Absolute Chemical Composition Control

Because the melt is protected from any external reactions, engineers have complete control over the alloy's final chemistry. Alloying elements can be added in precise amounts without fear of them being lost to oxidation.

This allows for the creation of alloys with extremely tight compositional tolerances, ensuring batch-to-batch consistency and reliable performance.

Uniform Temperature and Homogeneity

The induction heating process generates an electromagnetic field that naturally stirs the molten metal bath. This constant, non-contact stirring action is critical.

It ensures uniform temperature throughout the melt and guarantees that all alloying elements are distributed perfectly, preventing segregation and producing a completely homogenous final product.

Tailoring Material Microstructure

VIM systems allow for precise control over both heating and cooling rates. This enables metallurgists to manipulate the microstructure of the alloy—the size and arrangement of its crystal grains.

By controlling the microstructure, you can tailor the material's final properties, such as strength, ductility, and fatigue resistance, for a specific application.

Understanding the Trade-offs

No process is without its trade-offs. While VIM offers superior results, it's important to understand its practical considerations.

Higher Initial Capital Cost

VIM furnaces are complex systems that require robust vacuum chambers, powerful pumps, and sophisticated control systems. This makes their initial purchase and installation costs significantly higher than conventional air-melting furnaces.

Slower Batch Cycle Times

Achieving a high vacuum takes time. The process of pumping down the chamber, melting, refining, and controlled cooling means that VIM cycle times are inherently longer than those for simpler melting processes.

Operational Complexity

Operating and maintaining a VIM furnace requires highly skilled personnel. Managing the vacuum systems, control parameters, and furnace linings is more demanding than standard foundry work, adding to the operational overhead.

When to Choose VIM for Your Application

Your choice of melting technology must align with the demands of your final product. VIM is not a universal solution, but for certain goals, it is the only viable option.

- If your primary focus is ultimate material purity and performance (e.g., aerospace turbine blades, medical implants): VIM is the non-negotiable standard for creating defect-free materials where failure could have catastrophic consequences.

- If your primary focus is developing novel alloys with precise chemistry (e.g., research and development of new superalloys): VIM's controlled environment provides the only reliable way to guarantee compositional accuracy and repeatability.

- If your primary focus is cost-sensitive, high-volume production of standard-grade metals: A simpler process like air-melting or an Argon Oxygen Decarburization (AOD) converter might be more economical if the highest purity is not required.

Ultimately, selecting VIM is a strategic decision to prioritize material integrity and performance above all else.

Summary Table:

| Advantage | Key Benefit |

|---|---|

| Unmatched Purity | Eliminates atmospheric contamination and removes dissolved gases and volatile impurities. |

| Precise Control | Ensures exact chemical composition, uniform temperature, and tailored microstructure. |

| Superior Homogeneity | Produces defect-free, consistent materials with enhanced mechanical properties. |

Elevate your material performance with KINTEK's advanced high-temperature furnace solutions! Leveraging exceptional R&D and in-house manufacturing, we provide Vacuum Induction Melting (VIM) systems and other products like Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our deep customization capability ensures precise alignment with your unique experimental needs, delivering superior purity and reliability for industries such as aerospace and medical devices. Contact us today to discuss how we can optimize your metal production processes!

Visual Guide

Related Products

- Vacuum Induction Melting Furnace

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- Vacuum Hot Press Furnace Machine Heated Vacuum Press Tube Furnace

People Also Ask

- What are the key features and benefits of a Vacuum Induction Melting Furnace? Achieve High-Purity Metal Production

- What are the main industrial applications of vacuum melting furnaces? Achieve Unmatched Material Purity and Performance

- How is operator safety ensured during the vacuum induction melting process? Discover Multi-Layered Protection for Your Lab

- What are the key benefits of using vacuum melting furnaces? Achieve Superior Purity and Control for High-Performance Alloys

- What are the advantages of vacuum induction melting? Achieve Superior Purity for High-Performance Alloys