At its core, the popularity of induction furnaces in alloy manufacturing stems from their unique ability to produce an exceptionally uniform and flexible melt. This is achieved through a consistent, electromagnetic stirring action that ensures every component of the alloy is perfectly blended, leading to reliable, high-quality, and repeatable results.

The fundamental advantage of induction furnaces is not just heating the metal, but controlling it. The same electromagnetic field that generates heat also creates a natural stirring effect, solving the core challenge of achieving a perfectly homogeneous molten bath—a non-negotiable requirement for high-performance alloys.

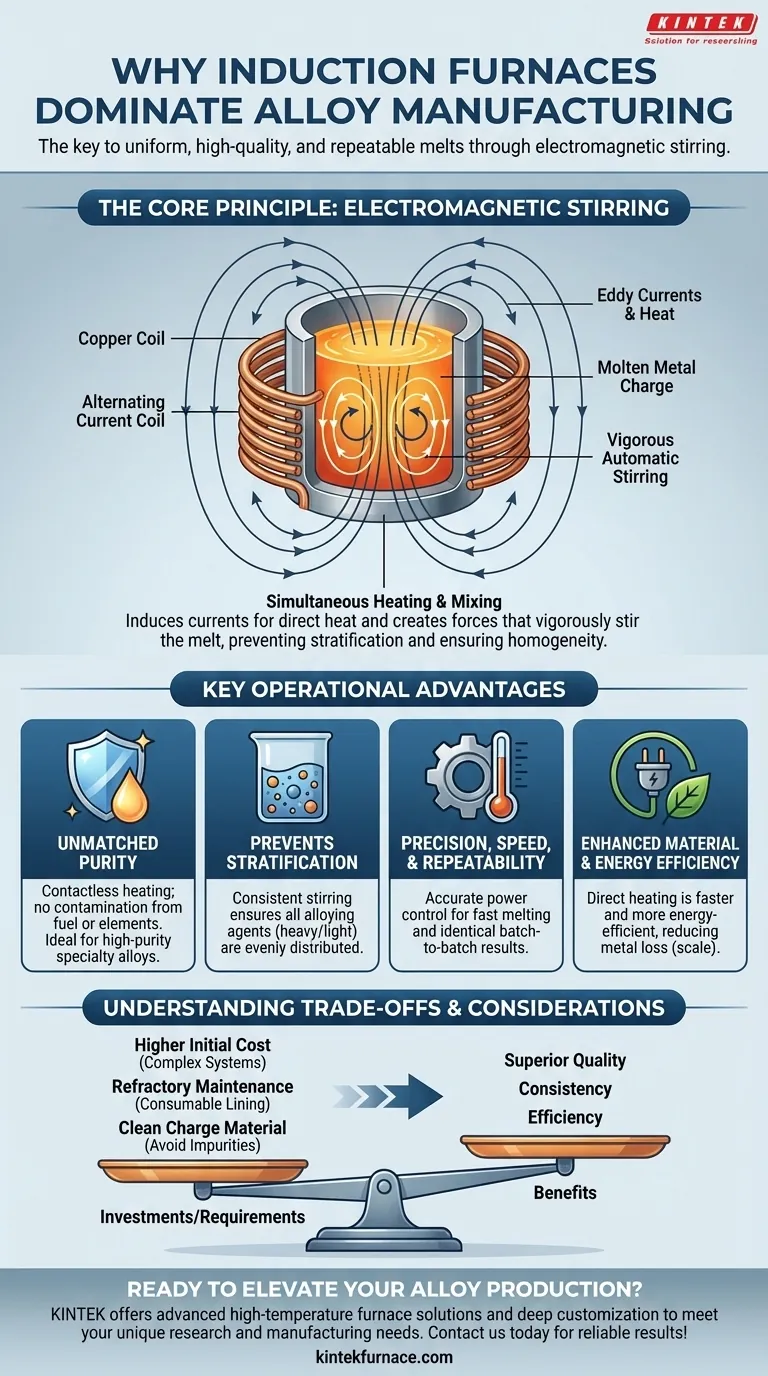

The Core Principle: Electromagnetic Stirring

The physics behind an induction furnace is what makes it so uniquely suited for creating precise metal alloys. It's a system designed for both heating and mixing simultaneously.

How It Creates a Uniform Melt

An induction furnace uses a powerful alternating current passed through a copper coil. This creates a strong, reversing magnetic field that induces electrical currents (eddy currents) directly within the metal charge inside the crucible.

These currents generate intense heat due to the metal's resistance, causing it to melt. Critically, the interaction of the magnetic field and the eddy currents also produces forces that vigorously and automatically stir the molten metal.

Why This Matters for Alloys

Alloys are made by combining elements that often have different densities and melting points. Without adequate mixing, heavier elements can sink and lighter ones can float, a phenomenon known as stratification.

The natural, consistent stirring action of an induction furnace prevents stratification. It ensures all alloying agents are distributed evenly throughout the entire molten bath, guaranteeing the final solidified product is homogenous and has the desired properties in every part.

Key Operational Advantages in Alloy Production

Beyond the essential stirring action, induction technology offers several other advantages that are critical for modern, high-specification alloy manufacturing.

Unmatched Purity and Cleanliness

Since the heat is generated within the metal itself, there is no contact with heating elements or combustion byproducts like gas or carbon. This is a contactless, clean melting process.

This lack of external contamination is vital for producing high-purity and specialty alloys where even trace amounts of impurities can compromise the material's final mechanical or chemical properties.

Precision, Speed, and Repeatability

Induction systems allow for very precise control over power input. This means melting temperatures can be reached quickly and held accurately, preventing overheating and the loss of valuable alloy elements through vaporization or oxidation.

This level of control makes the process highly repeatable. Once a melting profile is established for a specific alloy, it can be replicated identically, ensuring batch-to-batch consistency and meeting exact product specifications every time.

Enhanced Material and Energy Efficiency

The direct heating of the metal is far more energy-efficient than heating the entire chamber of a traditional furnace. This leads to lower energy consumption and reduced operational costs.

Faster melt times and a cleaner process also result in less metal loss to oxidation (scale), maximizing the yield from your raw materials.

Understanding the Trade-offs and Considerations

While highly effective, induction furnaces are not a universal solution. Understanding their limitations is key to making an informed decision.

Initial Investment Cost

The primary drawback of induction technology is a higher upfront capital cost compared to traditional fuel-fired furnaces. The power supplies and coil systems are complex and represent a significant investment.

Sensitivity to Charge Material

The clean nature of induction melting means there is little opportunity to burn off contaminants. Therefore, the raw material (the "charge") must be clean and of a known quality to avoid introducing impurities into the final alloy.

Refractory Lining Maintenance

The crucible, or refractory lining, that holds the molten metal is a consumable component. The intense heat and stirring action cause wear, and the lining must be regularly monitored, repaired, or replaced to prevent furnace failure.

Making the Right Choice for Your Goal

The decision to use an induction furnace should be aligned directly with your production priorities and the specific demands of the alloys you intend to manufacture.

- If your primary focus is high-performance, specialty alloys: The exceptional purity and homogeneity delivered by an induction furnace are non-negotiable to meet strict specifications.

- If your primary focus is high-volume, standard-grade alloys: The speed, repeatability, and energy efficiency of induction offer significant competitive advantages in cost and quality control.

- If your primary focus is versatility across many alloy types: The flexibility and precise control of an induction furnace allow you to easily switch between different alloy recipes with confidence.

Ultimately, mastering alloy production requires a process that provides absolute control, and induction furnaces offer the most direct path to achieving that.

Summary Table:

| Advantage | Description |

|---|---|

| Uniform Melt | Electromagnetic stirring prevents stratification, ensuring homogeneous alloys. |

| High Purity | Contactless heating eliminates contamination for clean, impurity-free melts. |

| Precision Control | Accurate temperature management enables repeatable, consistent results. |

| Energy Efficiency | Direct heating reduces energy use and operational costs. |

| Speed | Fast melting times increase productivity and material yield. |

Ready to elevate your alloy manufacturing with precision and purity? Leveraging exceptional R&D and in-house manufacturing, KINTEK provides diverse laboratories with advanced high-temperature furnace solutions. Our product line, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, is complemented by our strong deep customization capability to precisely meet your unique experimental requirements. Contact us today to discuss how our induction furnaces can deliver reliable, high-quality results for your alloy production needs!

Visual Guide

Related Products

- Vacuum Induction Melting Furnace

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

People Also Ask

- What role does a vacuum induction melting furnace play in Fe-5%Mn-C alloys? Ensure Chemical Integrity and High Purity

- What is the purpose of vacuum melting, casting and re-melting equipment? Achieve High-Purity Metals for Critical Applications

- What are some common applications of vacuum induction melting and casting (VIM&C)? Essential for Aerospace, Medical, and Nuclear Industries

- How has vacuum smelting impacted the development of superalloys? Unlock Higher Strength and Purity

- What are the common applications of Vacuum Induction Melting? Essential for High-Performance Metals and Alloys