In any induction furnace, precise temperature control is the single most critical factor for ensuring consistent product quality, operational efficiency, and metallurgical integrity. It dictates everything from the final alloy composition and mechanical properties to the prevention of costly defects, transforming the melting process from a simple act of heating into a controlled manufacturing discipline.

The core issue is not simply melting metal, but controlling its state with precision. Inaccurate temperature leads directly to inconsistent material properties, casting defects, and wasted energy, undermining the entire production process.

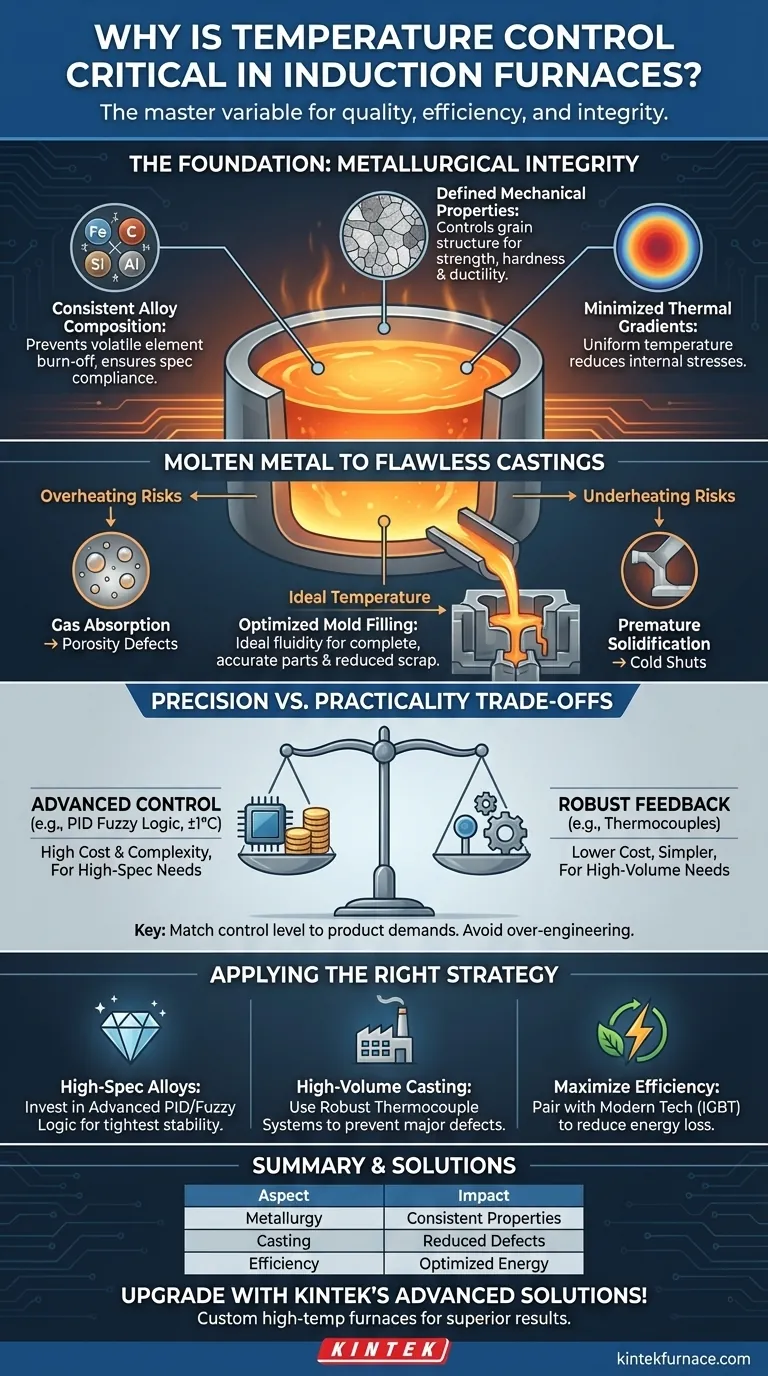

The Foundation of Quality: Metallurgical Integrity

The final properties of your metal are determined long before it is cast. They are forged in the molten bath, where temperature is the master variable.

Ensuring Consistent Alloy Composition

Every element in an alloy has a specific behavior at different temperatures. Excessive heat can cause volatile elements to burn off, altering the final composition and compromising the material's intended properties.

Stable temperature control ensures all elements remain properly dissolved and distributed throughout the melt, guaranteeing the alloy meets specification every time.

Defining Mechanical Properties

The temperature at which a metal is held and cast directly influences its grain structure. This structure, in turn, dictates critical mechanical properties like hardness, tensile strength, and ductility.

Without precise control, you introduce variability into the final product, leading to inconsistent performance and potential field failures.

Minimizing Thermal Gradients

Effective control systems work to maintain a minimal temperature difference between the core and the surface of the molten metal.

Large thermal gradients can create internal stresses and inconsistencies within the material, even before it is cast. Uniform temperature is the bedrock of a uniform, high-quality product.

From Molten Metal to Flawless Castings

The transition from a molten bath to a solid part is a process fraught with risk. The right temperature is your primary tool for mitigating these risks.

Preventing Porosity and Defects

Overheating the metal increases its ability to absorb gases like hydrogen and oxygen. These gases become trapped during solidification, creating porosity—a critical defect that weakens the final casting.

Conversely, underheating can cause the metal to solidify prematurely, resulting in incomplete fills, known as cold shuts.

Optimizing Mold Filling and Fluidity

Every casting has an ideal pouring temperature that ensures the metal has the right fluidity. This allows it to flow smoothly and fill every detail of the mold without eroding the mold surface or solidifying too quickly.

Precise temperature control enables this optimal fluidity, ensuring complex parts are formed completely and accurately. This directly reduces scrap rates and material waste.

Understanding the Trade-offs: Precision vs. Practicality

While temperature control is essential, the degree of precision required is a critical business decision involving clear trade-offs.

The Cost of Advanced Control

State-of-the-art systems, such as those using PID fuzzy logic, can maintain temperature stability within ±1°C. This level of precision is incredible but comes with higher capital investment and maintenance overhead.

The Complexity of Implementation

Advanced control systems are not "plug-and-play." They require careful integration, calibration, and skilled operators who understand how to use programmable heating curves and interpret feedback data.

A poorly implemented advanced system can create more problems than a well-managed, simpler one.

The Risk of Over-Engineering

Not every application requires sub-degree accuracy. The key is to match the level of control to the demands of the final product. A general-purpose casting may not justify the cost of a system designed for a high-performance aerospace alloy.

How to Apply This to Your Project

Your choice of temperature control strategy should be directly aligned with your primary operational goal.

- If your primary focus is producing high-spec alloys: Invest in advanced PID or fuzzy logic control systems to achieve the tightest possible temperature stability and guarantee metallurgical properties.

- If your primary focus is high-volume casting with good quality: Implement robust thermocouple feedback systems that prevent significant over- and under-heating to minimize defects and ensure consistent mold filling.

- If your primary focus is maximizing energy efficiency: Pair your temperature control system with modern furnace technology, such as IGBT inverters, to reduce energy loss and ensure more power is directed into the melt.

Ultimately, mastering temperature control is the most direct path to mastering your final product and its performance.

Summary Table:

| Aspect | Impact of Temperature Control |

|---|---|

| Metallurgical Integrity | Ensures consistent alloy composition and mechanical properties, minimizing defects. |

| Casting Quality | Prevents porosity and cold shuts, improving mold filling and reducing scrap rates. |

| Operational Efficiency | Optimizes energy use and process stability, lowering costs and enhancing throughput. |

| Control Strategies | Ranges from basic systems for general use to advanced PID/fuzzy logic for high precision. |

Upgrade your induction furnace with KINTEK's advanced solutions! Leveraging exceptional R&D and in-house manufacturing, we provide high-temperature furnaces like Muffle, Tube, Rotary, Vacuum & Atmosphere, and CVD/PECVD Systems, tailored to your unique needs. Our deep customization capabilities ensure precise temperature control for superior metallurgical results and operational efficiency. Don't let inconsistent temperatures compromise your production—contact us today to discuss how we can enhance your process and deliver reliable, high-quality outcomes!

Visual Guide

Related Products

- Vacuum Induction Melting Furnace

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- Laboratory Muffle Oven Furnace with Bottom Lifting

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

People Also Ask

- What are the advantages of vacuum induction melting? Achieve Superior Purity for High-Performance Alloys

- What are the main applications of vacuum induction melting (VIM) furnaces? Achieve Unmatched Metal Purity for Critical Industries

- What components make up a Vacuum Induction Melting Furnace? Discover the Key Systems for Pure Metal Melting

- How does vacuum induction melting work? Achieve Ultra-Pure, High-Performance Alloys

- What are the main industrial applications of vacuum melting furnaces? Achieve Unmatched Material Purity and Performance