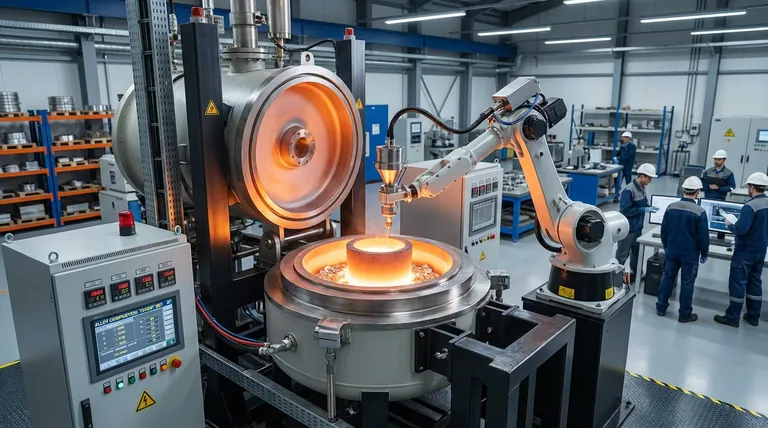

The precise addition of alloying elements in heavy-section Austempered Ductile Iron (ADI) is critical because the material's massive wall thickness causes internal cooling rates to be extremely slow. To counteract this, precision induction furnaces are used to accurately introduce elements like manganese, copper, nickel, and molybdenum. These additions increase hardenability, ensuring the material avoids the pearlite transformation zone during quenching and achieves the necessary austenitic matrix.

Core Takeaway In heavy-section ADI, the sheer mass of the material creates a "cooling lag" that threatens the microstructure. Precision induction alloying is the only way to chemically boost hardenability enough to bypass pearlite formation and secure a consistent austempered matrix deep within the core.

The Challenge of Heavy Sections

Dealing with Slow Cooling Rates

The defining characteristic of heavy-section ADI is its large wall thickness. This physical bulk retains significant heat, resulting in extremely slow internal cooling rates compared to thin-walled castings.

The Pearlite Transformation Zone

Slow cooling presents a metallurgical danger: it gives the material time to transform into pearlite during the quench. Pearlite formation is a failure mode in ADI production, as it prevents the material from reaching the required state for isothermal transformation.

The Role of Precision Alloying

Increasing Hardenability

To compensate for slow cooling, the chemical composition of the iron must be altered to increase its hardenability. High hardenability "delays" the transformation process, allowing the thick material to cool without reverting to pearlite.

The Essential Elements

The primary reference highlights four specific elements required for this task: manganese, copper, nickel, and molybdenum. These are not bulk fillers; they are precise chemical agents used to manipulate the metal's transformation thermodynamics.

Why Induction Technology is Necessary

Accuracy in Composition Design

Induction furnaces are required because they offer the precision control needed to hit exact alloying targets. Inaccurate additions could leave the material with insufficient hardenability, leading to microstructural inconsistencies in the center of the casting.

Targeting the Austenitic Matrix

The ultimate goal of this precise composition is to obtain a uniform austenitic matrix. This matrix is the prerequisite foundation for the subsequent isothermal transformation that gives ADI its unique mechanical properties.

Understanding the Trade-offs

Cost vs. Performance

Achieving high hardenability in heavy sections requires the use of expensive alloys like Nickel and Molybdenum. While this significantly drives up material costs, it is a non-negotiable trade-off to ensure structural integrity in thick parts.

Process Sensitivity

The reliance on precise alloying makes the melting process less forgiving. Deviations in the induction furnace settings can lead to "missed" chemistry, resulting in scrap castings that fail to meet the microstructural requirements at the core.

Making the Right Choice for Your Goal

To ensure success in heavy-section ADI production, consider the following regarding your alloy strategy:

- If your primary focus is Core Integrity: Prioritize the precise addition of Nickel and Molybdenum to maximize hardenability, ensuring the center of the casting avoids pearlite formation entirely.

- If your primary focus is Process Consistency: Utilize the induction furnace's control systems to maintain strict repeatability, as even minor fluctuations in Manganese or Copper can alter the quench response in thick sections.

Precision in the furnace is the only way to guarantee performance in the field.

Summary Table:

| Element | Primary Role in Heavy-Section ADI | Impact on Microstructure |

|---|---|---|

| Manganese | Increases Hardenability | Delays pearlite transformation during cooling |

| Copper | Promotes Austenite | Enhances matrix stability in thick walls |

| Nickel | Boosts Hardenability | Ensures core integrity despite slow internal cooling |

| Molybdenum | Prevents Pearlite | Critical for bypassing the pearlite nose in thick sections |

Elevate Your Metal Casting Precision with KINTEK

Achieving the perfect chemical composition in heavy-section Austempered Ductile Iron requires more than just high temperatures—it requires absolute control.

Backed by expert R&D and manufacturing, KINTEK offers specialized induction systems and laboratory high-temperature furnaces, including Muffle, Tube, Rotary, Vacuum, and CVD systems. Our solutions are fully customizable to meet your unique metallurgical needs, ensuring you achieve the consistent austenitic matrix required for superior ADI performance.

Ready to optimize your alloying process and eliminate casting failures?

References

- P. Lachart, Rainer Masendorf. Prediction of Cross-Section-Dependent ADI Microstructures by Experimental Heat Treatment Simulation. DOI: 10.1007/s40962-023-01246-9

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- Magnesium Extraction and Purification Condensing Tube Furnace

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

People Also Ask

- Why is a Vacuum Induction Melting (VIM) furnace essential? Secure Superalloy Purity and Performance

- How do induction furnaces enhance productivity in foundries? Boost Melting Speed and Automation for Higher Output

- How does an induction furnace heat metal? Achieve Fast, Clean, and Precise Metal Melting

- What is the function of a vacuum induction heating system in Al-Si and Al-Cu alloy prep? Ensuring Purity & Homogeneity

- Why is a vacuum arc furnace equipped with a flipping function for melting TixNbMoTaW? Achieve Alloy Homogeneity

- What is the role of a vacuum induction furnace in MRDO preparation? Enabling Rare Earth Magnet Recycling

- Why does increasing the section number of a cold crucible improve energy efficiency? Maximize Your Melting Potential

- Why are high-power converters and specific frequencies essential for Nb-MASC alloy melting? Achieve Perfect Homogeneity