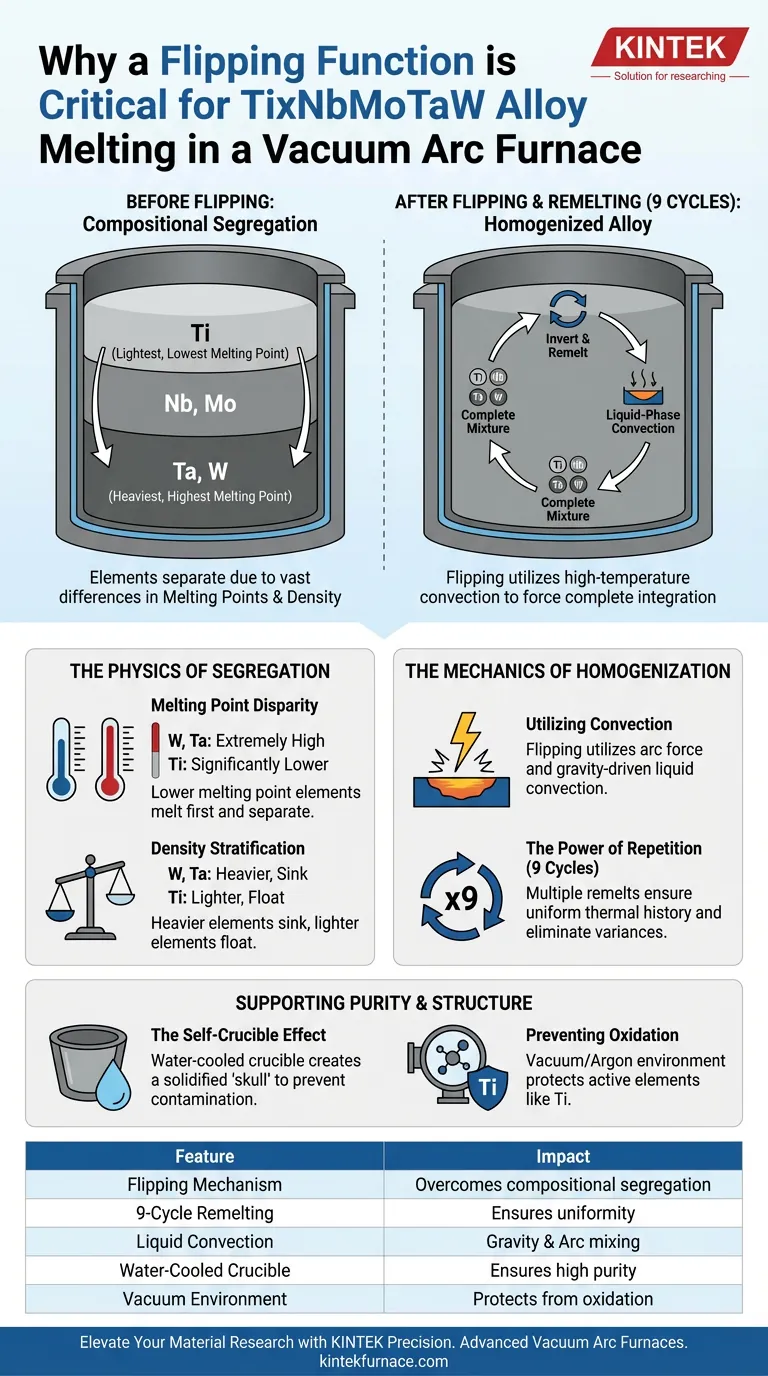

The flipping function is the critical mechanism for overcoming compositional segregation. Because the TixNbMoTaW alloy consists of refractory elements with vastly different melting points, a single pass results in an uneven mixture where elements fail to integrate fully. By flipping the crucible and remelting the ingot—typically up to nine times—the system utilizes high-temperature liquid-phase convection to force a complete mixture, ensuring the chemical and microstructural uniformity required for high-performance applications.

Refractory high-entropy alloys are inherently prone to separation due to the extreme variances in the physical properties of their constituent elements. The flipping mechanism transforms the melting process from a simple fusion event into a repeated mixing cycle, ensuring that varying densities and melting points are equalized throughout the ingot.

The Physics of Segregation

Melting Point Disparity

TixNbMoTaW is a refractory high-entropy alloy, meaning it contains elements like Tungsten (W) and Tantalum (Ta) which have extremely high melting points.

Conversely, Titanium (Ti) has a significantly lower melting point. Without mechanical intervention, the lower melting point elements may melt and separate before the refractory elements are fully fused, leading to severe compositional segregation.

Density Stratification

Beyond melting temperatures, these elements possess different atomic densities.

During a static melt, heavier elements naturally sink while lighter elements float. If the ingot is solidified without being inverted and remelted, the final material will exhibit macro-segregation, resulting in inconsistent mechanical properties across the sample.

The Mechanics of Homogenization

Utilizing Convection

The vacuum arc furnace relies on electric arcs to generate heat, but the arc force alone is often insufficient to mix a static pool of heavy liquid metal.

Flipping the ingot allows the system to utilize liquid-phase convection more effectively. By inverting the solid ingot and melting it again, you mechanically force the previously solidified "bottom" to become the "top," subjecting it to the direct energy of the arc and gravity-driven mixing.

The Power of Repetition

Achieving true homogeneity in TixNbMoTaW is rarely a single-step process.

According to standard protocols for this specific alloy, the ingot is typically remelted nine times. This repetition ensures that every region of the alloy undergoes the same thermal history, effectively eliminating chemical variances at both the macroscopic and microscopic scales.

Supporting Purity and Structure

The Self-Crucible Effect

The furnace uses a water-cooled copper crucible, which rapidly dissipates heat to create a solidified "skull" or shell between the melt and the crucible wall.

This prevents the molten alloy from reacting with the crucible material, ensuring high purity. However, this rapid cooling can freeze segregation in place, which makes the flipping and remelting function even more essential to break up those initial solidified structures.

Preventing Oxidation

While the flipping ensures mixing, the vacuum environment preserves the chemistry.

Active elements like Titanium are highly susceptible to oxidation at these temperatures. The vacuum or high-purity argon atmosphere protects these elements during the prolonged multi-cycle melting process required for homogenization.

Understanding the Trade-offs

Process Efficiency vs. Material Quality

The primary trade-off of this method is time and energy consumption.

Melting an ingot nine times drastically increases the cycle time compared to standard alloy production. However, for research-grade refractory alloys, this inefficiency is a necessary cost to achieve usable data; a segregated sample renders any testing of intrinsic mechanical properties invalid.

Cooling Rate Limitations

The water-cooled crucible promotes a fine microstructure but creates a steep thermal gradient.

While this is generally positive for strength, it means the window for liquid mixing is short before solidification occurs. If the flipping function is under-utilized (e.g., fewer than four cycles), the center of the ingot may remain chemically distinct from the surface.

Making the Right Choice for Your Goal

To maximize the quality of your TixNbMoTaW alloy, tailor your process to your specific requirements:

- If your primary focus is Chemical Uniformity: Prioritize a high number of remelting cycles (9+ for this specific alloy) to overcome density-driven segregation.

- If your primary focus is Purity: Ensure your vacuum system and argon purge are flawless, as the extended processing time increases the window for potential oxidation.

- If your primary focus is Microstructural Size: Rely on the rapid cooling of the copper crucible, but verify that this rapid solidification hasn't trapped unmelted refractory particles.

By leveraging the flipping function to drive repeated convection, you convert a chaotic mix of elements into a single, high-performance material.

Summary Table:

| Feature | Impact on TixNbMoTaW Alloy Production |

|---|---|

| Flipping Mechanism | Overcomes compositional segregation by inverting the ingot for remelting. |

| 9-Cycle Remelting | Ensures chemical and microstructural uniformity across all alloy regions. |

| Liquid Convection | Gravity and arc-driven mixing of elements with disparate melting points. |

| Water-Cooled Crucible | Creates a 'skull' to prevent contamination while ensuring high purity. |

| Vacuum Environment | Protects active elements like Ti from oxidation during long melt cycles. |

Elevate Your Material Research with KINTEK Precision

Achieving perfect homogeneity in refractory high-entropy alloys like TixNbMoTaW requires specialized equipment designed for extreme conditions. Backed by expert R&D and world-class manufacturing, KINTEK provides advanced Vacuum Arc Furnaces, Muffle, Tube, Rotary, and CVD systems tailored for high-temperature lab applications.

Our systems are fully customizable to meet your unique metallurgical needs—ensuring every melt achieves the purity and uniformity your research demands. Contact us today to optimize your alloy production!

Visual Guide

References

- Ruisheng Zhao, Chao Chang. Microstructure and Mechanical Properties of TixNbMoTaW Refractory High-Entropy Alloy for Bolt Coating Applications. DOI: 10.3390/coatings15020120

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- Vacuum Heat Treat Sintering and Brazing Furnace

- Vacuum Heat Treat Sintering Furnace Molybdenum Wire Vacuum Sintering Furnace

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

People Also Ask

- Why are Water Cooled Copper Pots utilized during the melting process of titanium alloys? Ensure Purity with Skull Melting

- What is a resonant tank circuit and how is it used in the described induction heater? Boost Efficiency with Energy Oscillation

- What is a vacuum casting furnace and what is its primary purpose? Achieve Purity in High-Performance Metal Casting

- What are the benefits of vacuum induction smelting technology? Achieve Superior Purity and Performance for Advanced Materials

- What other applications beyond melting can induction heating systems perform? Unlock Precision in Joining, Heat Treating & More

- How does the k-epsilon turbulence model with wall functions aid melt flow simulation? Optimize Induction Furnaces

- In which industries is IGBT-powered induction melting widely used? A Guide to High-Performance Metal Melting

- What is a vacuum induction furnace and how does it differ from other vacuum sintering furnaces? Discover the Key Differences