To put it simply, induction furnaces enhance foundry productivity through a powerful combination of rapid melting rates, compatibility with automation, and minimal downtime between batches. This allows foundries to produce more metal, more quickly, and with greater consistency than is possible with traditional furnaces like cupolas or arc furnaces.

The true advantage of induction technology is not a single feature, but its holistic impact on the production cycle. By accelerating melting while simultaneously improving control and reducing waste, it fundamentally streamlines the entire casting process from start to finish.

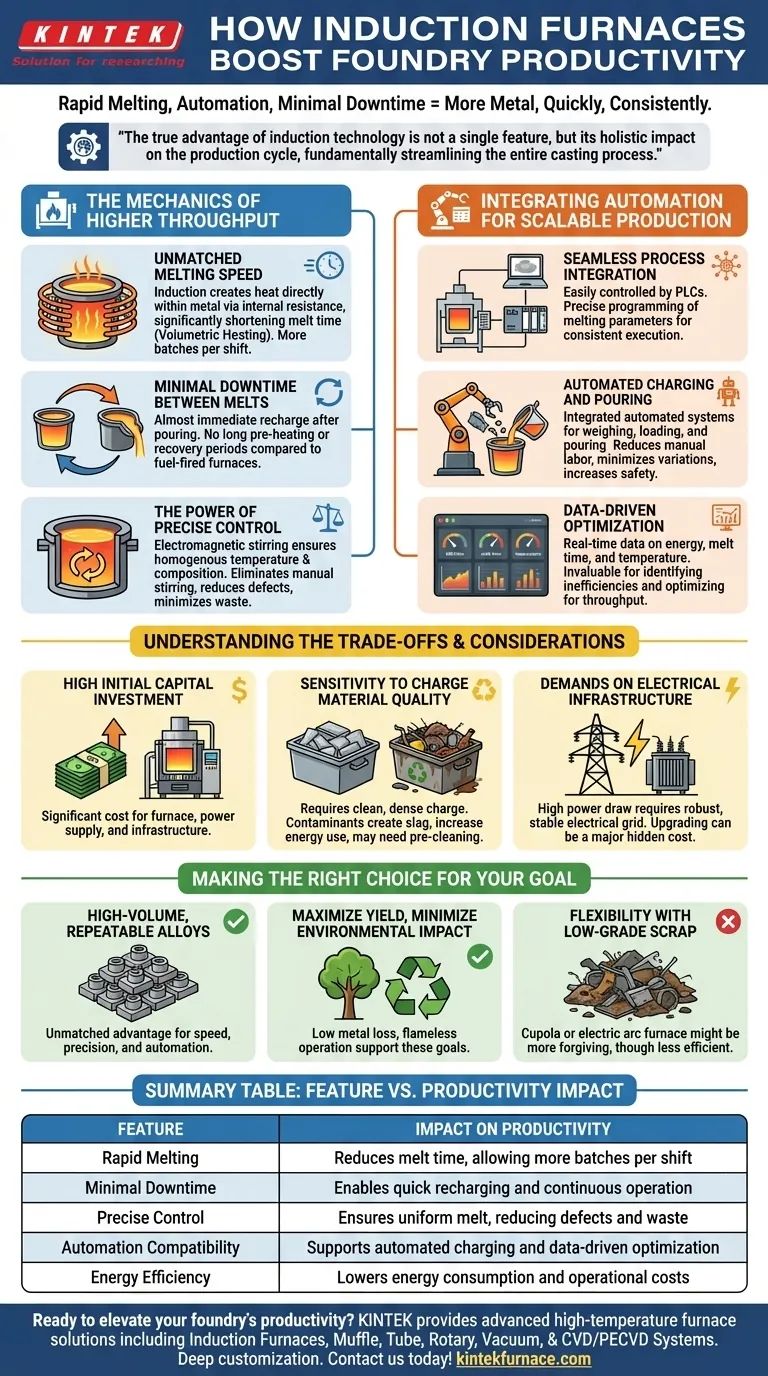

The Mechanics of Higher Throughput

The productivity gains from induction furnaces begin with the core physics of how they operate. Unlike furnaces that heat from the outside-in, induction creates heat directly within the metal itself.

Unmatched Melting Speed

An induction coil generates a powerful magnetic field, which induces intense electrical currents within the metallic charge material. This internal resistance heating is incredibly fast and efficient, significantly shortening the time required to bring a full batch of metal to pouring temperature.

This process, known as volumetric heating, means less time is spent waiting for the melt, directly increasing the number of batches that can be processed per shift.

Minimal Downtime Between Melts

Once a batch is poured, an induction furnace can be recharged and begin the next cycle almost immediately. There are no long pre-heating or recovery periods.

This contrasts sharply with fuel-fired furnaces that require extensive time to reach and maintain operating temperatures, creating significant non-productive gaps in the production schedule.

The Power of Precise Control

The magnetic field also creates a natural stirring action within the molten bath. This electromagnetic stirring ensures the melt is perfectly homogenous in both temperature and chemical composition.

This eliminates the need for manual stirring, reduces the risk of defects from inconsistent alloys, and minimizes rejected castings—a major source of lost productivity.

Integrating Automation for Scalable Production

The electrical nature of induction furnaces makes them uniquely suited for modern, automated foundry environments, turning a manual process into a highly repeatable and data-driven operation.

Seamless Process Integration

Induction power supplies are easily controlled by PLCs (Programmable Logic Controllers) and other plant-wide management systems. This allows melting parameters like power level and temperature to be programmed and executed with perfect precision every time.

Automated Charging and Pouring

These furnaces can be integrated with automated systems that handle the weighing and loading of raw materials and the robotic control of pouring. This reduces reliance on manual labor, minimizes cycle time variations, and increases operator safety.

Data-Driven Optimization

Modern induction systems provide a constant stream of real-time data on energy consumption (kWh/ton), melt time, and temperature. This information is invaluable for identifying inefficiencies and continuously optimizing the process for maximum throughput and minimum cost.

Understanding the Trade-offs and Considerations

While highly productive, induction technology is not a universal solution. A clear-eyed assessment of its limitations is essential for making an informed decision.

High Initial Capital Investment

The initial purchase and installation cost of an induction furnace system, including its sophisticated power supply and cooling infrastructure, is significant. This represents a major capital expenditure compared to some simpler, older furnace types.

Sensitivity to Charge Material Quality

Induction furnaces perform best with clean, dry, and relatively dense charge material. Excessive dirt, oil, rust, or other contaminants can create slag, increase energy consumption, and negatively impact the melting process. This may necessitate a pre-cleaning step, which can add time and cost.

Demands on Electrical Infrastructure

These are high-powered electrical devices. A foundry must have a robust and stable electrical grid capable of handling the substantial power draw without causing disruptions to the plant or the local utility network. Upgrading this infrastructure can be a major hidden cost.

Making the Right Choice for Your Goal

Ultimately, the decision to invest in induction technology must align with your foundry's specific operational priorities.

- If your primary focus is high-volume, repeatable production of specific alloys: The speed, precision, and automation-readiness of induction furnaces offer an unmatched advantage.

- If your primary focus is maximizing material yield and minimizing environmental impact: The low metal loss and flameless operation of induction technology directly support these goals.

- If your primary focus is flexibility with low-grade, contaminated scrap material: A cupola or electric arc furnace might be a more forgiving, albeit less efficient, option.

By aligning the technology's core strengths with your production goals, you can confidently determine if an induction furnace is the right tool to drive your foundry's productivity forward.

Summary Table:

| Feature | Impact on Productivity |

|---|---|

| Rapid Melting | Reduces melt time, allowing more batches per shift |

| Minimal Downtime | Enables quick recharging and continuous operation |

| Precise Control | Ensures uniform melt, reducing defects and waste |

| Automation Compatibility | Supports automated charging and data-driven optimization |

| Energy Efficiency | Lowers energy consumption and operational costs |

Ready to elevate your foundry's productivity? Leveraging exceptional R&D and in-house manufacturing, KINTEK provides advanced high-temperature furnace solutions, including Induction Furnaces, Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures we precisely meet your unique experimental and production needs. Contact us today to discuss how our tailored solutions can boost your efficiency and output!

Visual Guide

Related Products

- Vacuum Induction Melting Furnace

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

People Also Ask

- What industries benefit from Vacuum Induction Melting Furnaces? Unlock High-Purity Metals for Aerospace, Medical, and More

- What are the advantages of vacuum induction melting? Achieve Superior Purity for High-Performance Alloys

- What are the key components of a Vacuum Induction Melting (VIM) furnace? Master High-Purity Metal Processing

- What are the key benefits of using vacuum melting furnaces? Achieve Superior Purity and Control for High-Performance Alloys

- What are the main industrial applications of vacuum melting furnaces? Achieve Unmatched Material Purity and Performance