In a Vacuum Induction Melting (VIM) furnace, the vacuum environment is not merely a protective shield but an active and indispensable part of the metallurgical process. Its primary purpose is to create an ultra-pure environment that prevents atmospheric gases from contaminating the molten metal. This allows for the removal of dissolved impurities and grants operators precise control over the final chemical composition, resulting in materials with superior quality and performance.

The core takeaway is that a vacuum does more than just prevent oxidation. It acts as a powerful refining tool, actively purifying the molten metal by removing unwanted gases and volatile elements, which is fundamental to producing the high-performance alloys required by advanced industries.

The Core Functions of the Vacuum Environment

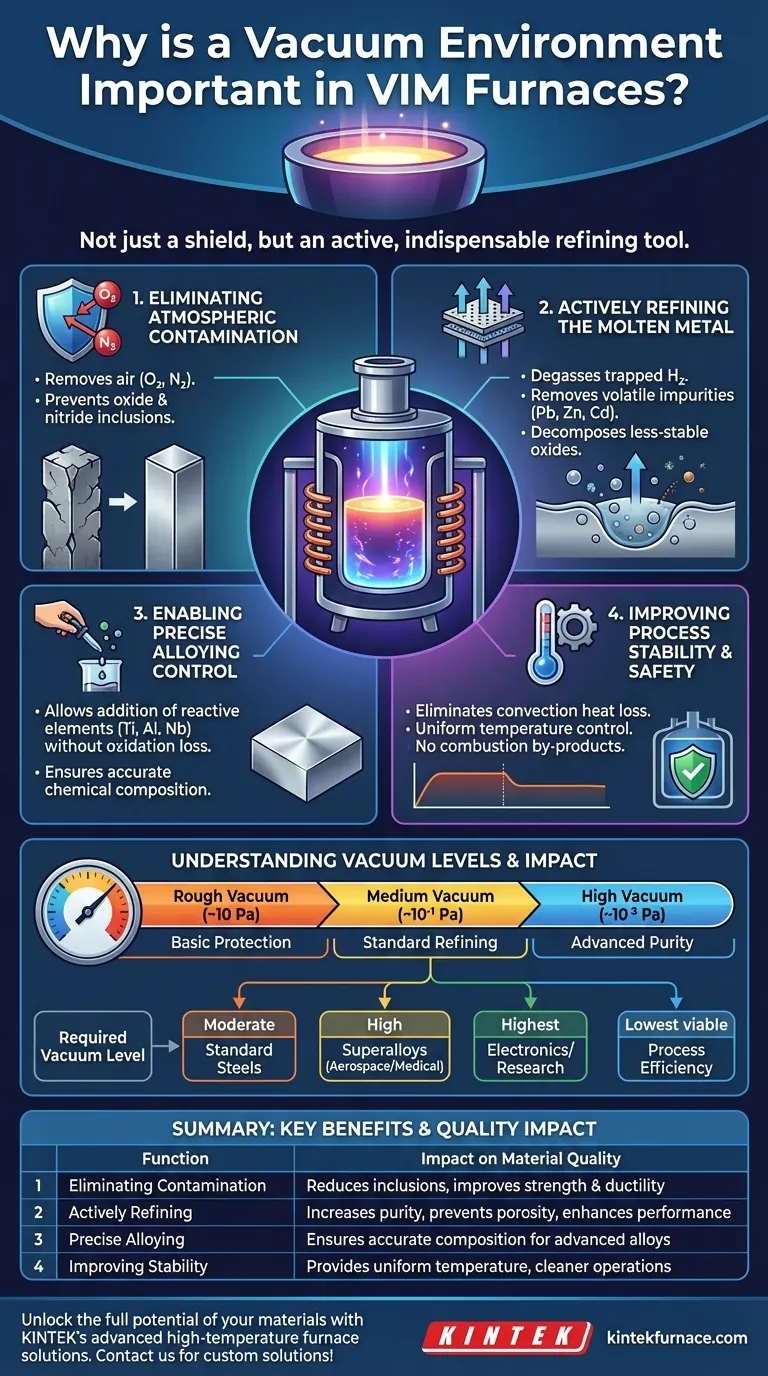

The importance of the vacuum can be understood by examining its four critical functions during the melting process. Each plays a distinct role in transforming raw materials into a high-purity, precision-engineered final product.

Function 1: Eliminating Atmospheric Contamination

The most immediate benefit of a vacuum is the removal of the atmosphere. Air is approximately 78% nitrogen and 21% oxygen, both of which are highly reactive with molten metals.

Oxygen causes the formation of oxides, which create solid inclusions in the final casting. These inclusions act as stress points, reducing the material's strength, ductility, and fatigue life.

Nitrogen can form nitrides in a similar fashion, leading to embrittlement. By physically removing these gases, the vacuum ensures the melt remains clean and free from these detrimental reactions.

Function 2: Actively Refining the Molten Metal

A vacuum is not passive; it actively purifies the metal by changing the physical chemistry of the melt.

First, it enables degassing. Dissolved gases, particularly hydrogen, are trapped within the metal. Under vacuum, these gases have a strong tendency to come out of the solution and be pumped away. This prevents porosity (gas bubbles) in the final product.

Second, it removes volatile impurities. Elements with high vapor pressure, such as lead, cadmium, zinc, and bismuth, will essentially boil off under vacuum at melting temperatures. The vacuum system then removes these vaporized elements, significantly increasing the purity of the alloy.

Finally, a deep vacuum can even cause the decomposition of less-stable oxides that may have been present in the raw materials, further refining the melt beyond what is possible in air.

Function 3: Enabling Precise Alloying Control

Many advanced superalloys depend on the precise addition of highly reactive elements like titanium, aluminum, and niobium.

In a normal atmosphere, these elements would instantly oxidize upon being added to the melt, making it impossible to control their final concentration in the alloy.

The vacuum creates a pristine "blank slate." It allows metallurgists to add these reactive elements with confidence, knowing they will dissolve into the alloy as intended, not be lost as oxide slag. It also permits the controlled backfilling of a specific gas, like argon, if a certain partial pressure is required for the process.

Function 4: Improving Process Stability and Safety

By removing air, the vacuum eliminates heat loss through convection. Heat transfer occurs primarily through radiation, which is more predictable and allows for more uniform temperature control within the crucible.

Furthermore, since VIM furnaces use electromagnetic induction for heating, there are no combustion by-products. This, combined with the enclosed vacuum environment, results in a significantly cleaner and safer process compared to atmosphere-based furnaces.

Understanding Vacuum Levels and Their Impact

Not all vacuums are created equal. The "degree" of vacuum, or how low the pressure is, directly impacts the refining process. The chosen level is a critical trade-off between metallurgical requirements and operational cost.

The Concept of Vacuum Degree

Vacuum level is measured in units of pressure, like Pascals (Pa) or millibars (mbar). A lower pressure value means a higher (or deeper) vacuum.

Typical operational ranges include rough vacuum (around 10 Pa), medium vacuum (down to 10⁻¹ Pa), and high vacuum (10⁻³ Pa or lower).

How Vacuum Level Affects Purity

A rough vacuum is sufficient to prevent gross oxidation and remove the bulk of dissolved gases like hydrogen. This is adequate for many standard grades of steel and less-reactive alloys.

Achieving a high vacuum is necessary for more demanding tasks, such as removing volatile trace elements or breaking down stable oxides. The production of aerospace superalloys and high-purity medical implants requires these high-vacuum levels to achieve the necessary purity and material properties.

The Engineering Trade-off

Achieving and maintaining a high vacuum is more expensive and time-consuming. It requires more sophisticated and powerful pumps, robust chamber construction, and longer pump-down cycles.

Therefore, the choice of vacuum level is an engineering decision that balances the required material purity against the cost and time of the manufacturing process.

Making the Right Choice for Your Goal

The required vacuum environment is dictated entirely by the final application of the material you are producing.

- If your primary focus is producing standard steels or less-reactive alloys: A moderate vacuum is sufficient to prevent major oxidation and remove dissolved gases that cause porosity.

- If your primary focus is creating superalloys for aerospace or medical use: A high-vacuum environment is non-negotiable to control the chemistry of reactive elements and achieve extreme purity.

- If your primary focus is maximizing purity for electronics or research: The highest achievable vacuum is necessary to drive off trace volatile elements and ensure the cleanest possible material.

- If your primary focus is process efficiency and cost: Your goal is to use the lowest vacuum level that still meets the minimum quality specifications for the alloy, balancing metallurgical quality against cycle time.

Ultimately, mastering the vacuum environment is what separates standard metal production from the creation of truly advanced materials.

Summary Table:

| Function | Key Benefit | Impact on Material Quality |

|---|---|---|

| Eliminating Atmospheric Contamination | Prevents oxidation and nitride formation | Reduces inclusions, improves strength and ductility |

| Actively Refining the Molten Metal | Removes dissolved gases and volatile impurities | Increases purity, prevents porosity, and enhances performance |

| Enabling Precise Alloying Control | Allows addition of reactive elements without loss | Ensures accurate chemical composition for advanced alloys |

| Improving Process Stability and Safety | Reduces heat loss and eliminates combustion risks | Provides uniform temperature control and cleaner operations |

Unlock the full potential of your materials with KINTEK's advanced high-temperature furnace solutions! Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with precision-engineered products like Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures we can precisely meet your unique experimental requirements, helping you achieve superior purity and performance in alloys for industries such as aerospace, medical, and electronics. Contact us today to discuss how we can tailor a solution for your needs and elevate your metallurgical processes!

Visual Guide

Related Products

- Vacuum Induction Melting Furnace

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

- Vacuum Hot Press Furnace Machine Heated Vacuum Press Tube Furnace

- Vacuum Hot Press Furnace Machine Heated Vacuum Press

People Also Ask

- How has vacuum smelting impacted the development of superalloys? Unlock Higher Strength and Purity

- How does vacuum melting technology contribute to sustainability? Boost Durability and Recycling Efficiency

- What is vacuum induction melting technology and why is it important? Achieve High-Purity Metals for Critical Applications

- What are the common applications of Vacuum Induction Melting? Essential for High-Performance Metals and Alloys

- What role does a vacuum induction melting furnace play in Fe-5%Mn-C alloys? Ensure Chemical Integrity and High Purity