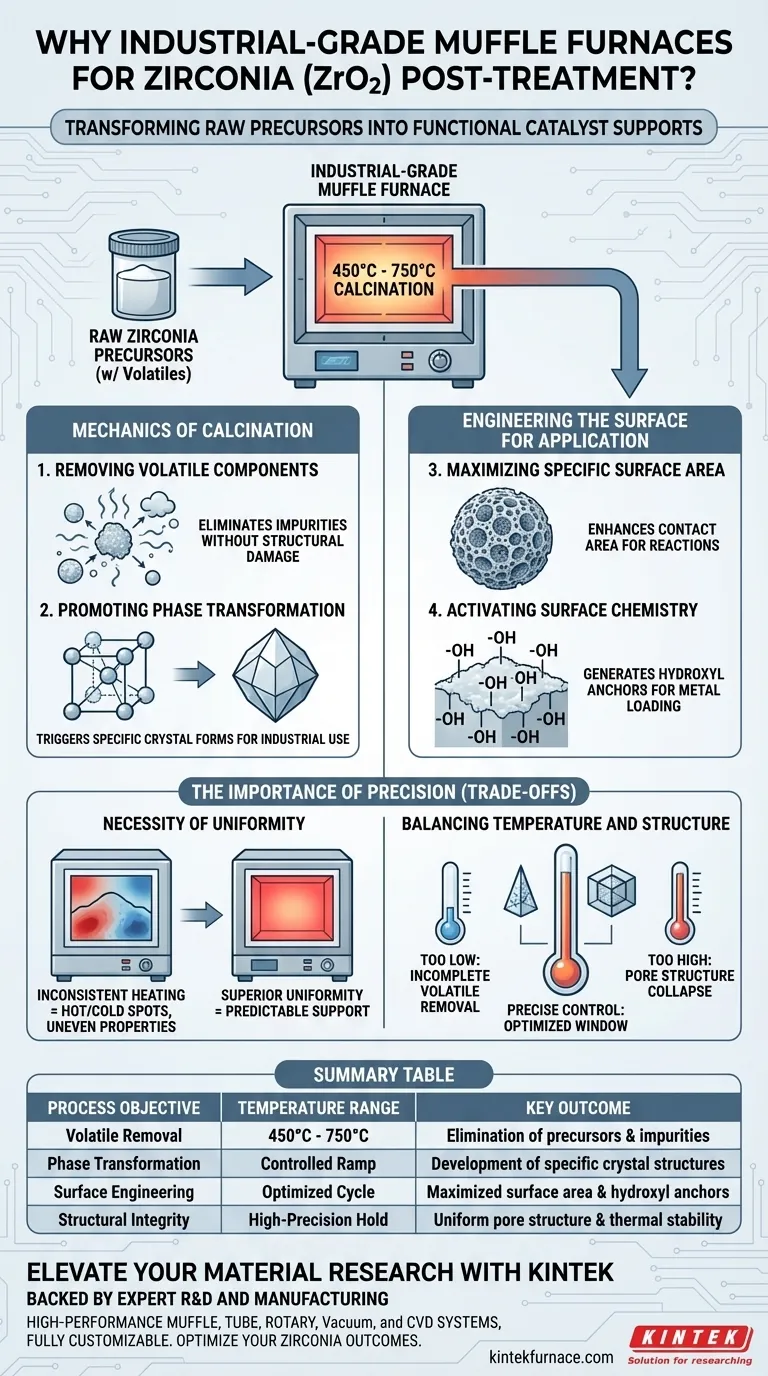

An industrial-grade muffle furnace is the primary instrument used to transform raw Zirconia precursors into functional catalyst supports. It executes a high-temperature calcination process, strictly controlled between 450°C and 750°C, to ensure the material achieves the necessary physical and chemical stability.

The core function of the furnace is not simply drying the material, but actively engineering its microstructure. By controlling the thermal environment, the furnace facilitates the phase transformations and surface chemistry changes required to create an ideal platform for subsequent metal loading.

The Mechanics of Calcination

Removing Volatile Components

The initial role of the muffle furnace is purification. Zirconia precursors often contain volatile compounds that must be eliminated before the material can be used.

The furnace provides a controlled environment within the 450°C to 750°C range. This heat effectively drives off these volatiles without damaging the underlying structure.

Promoting Phase Transformation

Beyond purification, the thermal energy triggers a critical physical change in the material.

The heat induces a specific phase transformation within the Zirconia. This ensures the support adopts the precise crystal forms necessary for its intended industrial application.

Engineering the Surface for Application

Maximizing Specific Surface Area

For a support material to be effective, it must offer a massive surface area for interaction.

The calcination process is tuned to result in a Zirconia support with a high specific surface area. This maximizes the contact area available for chemical reactions or further processing.

Activating Surface Chemistry

The most critical outcome of this thermal treatment is the modification of surface chemistry.

The process generates abundant surface hydroxyl functional groups. These groups serve as chemical "anchors," making the Zirconia an ideal physical platform for subsequent metal loading.

The Importance of Precision (Trade-offs)

The Necessity of Uniformity

Industrial-grade muffle furnaces are required because they offer superior heating uniformity compared to standard heating methods.

Inconsistent heating can lead to "hot spots" or "cold spots" in the batch. This results in uneven phase transformations, creating a support with unpredictable physical properties.

Balancing Temperature and Structure

There is a trade-off between calcination temperature and surface area.

If the temperature is too low, volatile removal is incomplete; if it is too high, the pore structure may collapse. The precise temperature control of an industrial furnace is essential to navigate this narrow window.

Making the Right Choice for Your Goal

To ensure your Zirconia supports are optimized for their final application, consider the following parameters during post-treatment:

- If your primary focus is Metal Loading: Ensure the furnace is calibrated to maximize the retention of surface hydroxyl functional groups, which serve as the binding sites for metals.

- If your primary focus is Structural Integrity: Prioritize the phase transformation aspect of the calcination profile to ensure the specific crystal forms are fully developed.

Precision in thermal processing is the difference between a raw precursor and a high-performance catalyst support.

Summary Table:

| Process Objective | Temperature Range | Key Outcome |

|---|---|---|

| Volatile Removal | 450°C - 750°C | Elimination of precursors & impurities |

| Phase Transformation | Controlled Ramp | Development of specific crystal structures |

| Surface Engineering | Optimized Cycle | Maximized surface area & hydroxyl anchors |

| Structural Integrity | High-Precision Hold | Uniform pore structure & thermal stability |

Elevate Your Material Research with KINTEK

Precision thermal processing is the difference between a raw precursor and a high-performance catalyst support. Backed by expert R&D and manufacturing, KINTEK offers high-performance Muffle, Tube, Rotary, Vacuum, and CVD systems—all fully customizable to meet your specific Zirconia processing needs.

Our industrial-grade furnaces ensure the heating uniformity and strict temperature control required for critical phase transformations and surface activation. Contact us today to discuss your unique laboratory requirements and see how our advanced heating solutions can optimize your material outcomes.

Visual Guide

References

- Yuze Wu, He Tian. Preparation of a Pd/Ni Bimetallic Catalyst and its Application in the Selective Hydrogenation of Phenol. DOI: 10.61187/ita.v3i2.209

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- 1400℃ Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

People Also Ask

- How does a high-precision programmable muffle furnace improve creep testing? Ensure Accuracy in Titanium Alloys

- What key components are used in vacuum muffle furnaces to ensure precise gas dispersion? Discover the MFC and BPR System

- How has technology improved muffle furnace performance? Achieve Precision, Efficiency, and Purity in Heating

- How does a muffle furnace differ from a pusher furnace? Choose the Right Furnace for Your Lab

- What maintenance is required for a muffle furnace? Ensure Long-Term Reliability and Safety

- How does a muffle furnace ensure the quality of high-temperature solid-state synthesis? Achieve Superior Phase Purity

- What are the applications of muffle furnaces? Essential for High-Temperature Material Processing

- What role does temperature control play in a muffle furnace? Unlock Precision and Reliability for Your Lab