In essence, temperature control is the operational brain of a muffle furnace. It is the system responsible for setting a desired temperature, actively monitoring the internal conditions, and adjusting power to the heating elements to achieve and maintain that temperature with precision. Modern systems allow for intricate control over the entire heating and cooling cycle.

The role of temperature control extends far beyond simply heating a chamber. It is the critical factor that ensures consistent, repeatable results, protects the integrity of both the material being processed and the furnace itself, and transforms a basic heating box into a precise scientific tool.

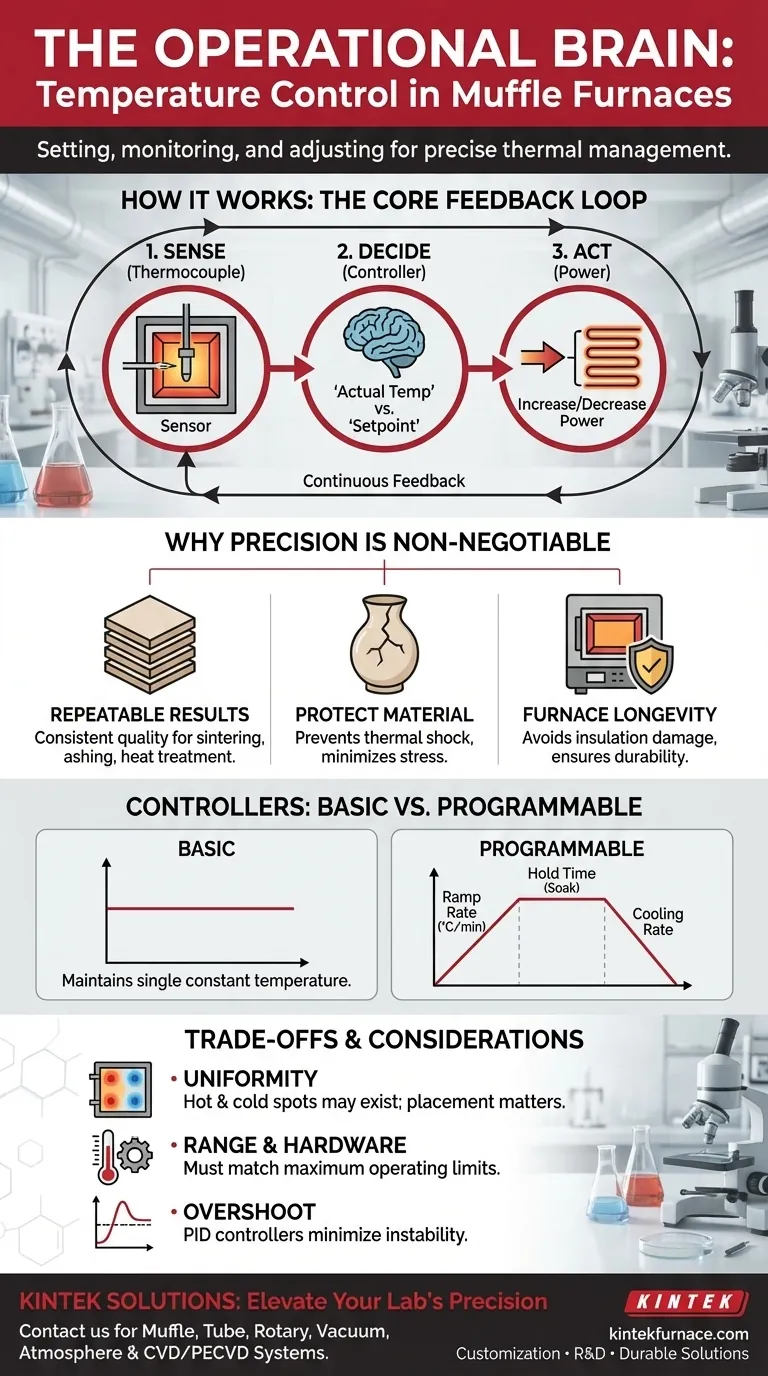

How Temperature Control Works: The Core Mechanism

A muffle furnace's temperature control system operates on a continuous feedback loop. Understanding this mechanism is key to appreciating its importance.

The Control Loop: Sense, Decide, Act

The system has three primary components. First, a temperature sensor (typically a thermocouple) placed inside the chamber constantly measures the actual temperature.

Second, this sensor sends its reading to the temperature controller, which is the decision-making unit. The controller compares the actual temperature to the user-defined target temperature (the "setpoint").

Finally, based on this comparison, the controller adjusts the power sent to the furnace's heating elements. If the temperature is too low, it increases power; if it's too high, it reduces or cuts power.

Basic vs. Programmable Controllers

The simplest controllers maintain a single, constant temperature. You set the temperature, and the furnace heats up and holds it there.

More advanced programmable controllers are now standard for technical applications. They allow users to define a complete thermal profile, including:

- Ramp Rate: How quickly the furnace heats up (°C/minute).

- Hold Time (Soak): How long the furnace stays at the target temperature.

- Cooling Rate: The rate at which the furnace is allowed to cool down.

Why Precision Is Non-Negotiable

Minor deviations in temperature can have significant consequences. Precise control is not a luxury; it is a fundamental requirement for reliable work.

Ensuring Repeatable and Accurate Results

For processes like sintering, ashing, and heat treatment, the material's final properties are directly tied to the temperatures it experiences.

Without exact control, you cannot guarantee that two separate batches will be processed identically. This makes results inconsistent and unreliable for any scientific testing or quality control application.

Protecting Material Integrity

The rate of temperature change is often just as important as the peak temperature. Rapid, uncontrolled heating can induce thermal shock, causing cracks or other damage to the material being processed.

A controlled ramp rate ensures the item heats up evenly, minimizing internal stresses.

Maintaining Furnace Longevity

The furnace itself is vulnerable to thermal shock. Excessive or extremely rapid heating can cause small cracks to form in the furnace's ceramic insulation or muffle.

Over time, this damage compromises the furnace's efficiency and structural integrity. Proper temperature control is a crucial part of equipment maintenance.

Understanding the Trade-offs and Limitations

Even the best temperature control system operates within certain constraints. Being aware of these is essential for accurate work.

Temperature Uniformity vs. Control

A controller provides precise temperature management at the location of the thermocouple. However, the temperature may not be perfectly uniform throughout the entire chamber.

Hot and cold spots can exist. The accuracy of your process depends on knowing your furnace's temperature uniformity and placing samples accordingly.

The Importance of the Correct Temperature Range

A sophisticated controller is useless if the furnace's hardware cannot meet the demands of your application. The heating elements must be capable of reaching and sustaining the required temperatures.

Always ensure the furnace's specified maximum operating temperature provides a safe margin above your process needs.

Overshoot and Undershoot

Simpler control systems can sometimes overshoot the target temperature before settling down. While often minor, this can be problematic for highly sensitive materials.

More advanced PID (Proportional-Integral-Derivative) controllers are designed to anticipate this, minimizing overshoot and providing a much more stable and accurate hold at the setpoint.

Making the Right Choice for Your Application

The level of temperature control you need is dictated entirely by your goal.

- If your primary focus is simple drying or binder burnout: A basic digital controller that can reliably hold a single setpoint is often sufficient.

- If your primary focus is materials science or complex heat treating: A programmable controller is essential for defining the precise ramp, soak, and cooling cycles these processes demand.

- If your primary focus is process validation for regulated industries: You need a high-precision, calibrated controller, often with data logging capabilities to ensure full traceability and compliance.

Ultimately, mastering temperature control is what transforms a muffle furnace from a simple oven into a precise scientific instrument.

Summary Table:

| Aspect | Role of Temperature Control |

|---|---|

| Mechanism | Uses feedback loop with sensor, controller, and power adjustment for precise heating and cooling cycles. |

| Benefits | Ensures repeatable results, prevents thermal shock, and maintains furnace longevity. |

| Key Features | Includes programmable controllers for ramp rates, hold times, and cooling profiles. |

| Applications | Essential for sintering, ashing, heat treatment, and regulated industry compliance. |

Ready to elevate your lab's precision? KINTEK specializes in advanced high-temperature furnace solutions, including Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. With our strong R&D and deep customization capabilities, we tailor solutions to meet your unique experimental needs—ensuring consistent results and equipment durability. Contact us today to discuss how we can support your specific applications!

Visual Guide

Related Products

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1400℃ Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- What role does a muffle furnace play in the preparation of MgO support materials? Master Catalyst Activation

- What is the role of a muffle furnace in the study of biochar regeneration and reuse? Unlock Sustainable Water Treatment

- What environmental conditions are critical for SiOC ceramicization? Master Precise Oxidation & Thermal Control

- What is the role of a muffle furnace in the synthesis of water-soluble Sr3Al2O6? Precision in SAO Production

- What metals cannot be heated by induction? Understanding Material Suitability for Efficient Heating