In short, technology has transformed muffle furnaces from simple high-temperature ovens into highly precise, efficient, and clean instruments. Key improvements in materials for heating elements and insulation, combined with intelligent design, provide vastly superior control over temperature and prevent cross-contamination of samples.

The core advancement is a shift from brute-force heating to systemic control. Modern muffle furnaces are not just hotter; they are engineered systems that deliver precise, uniform, and uncontaminated heat with greater energy efficiency and reliability than ever before.

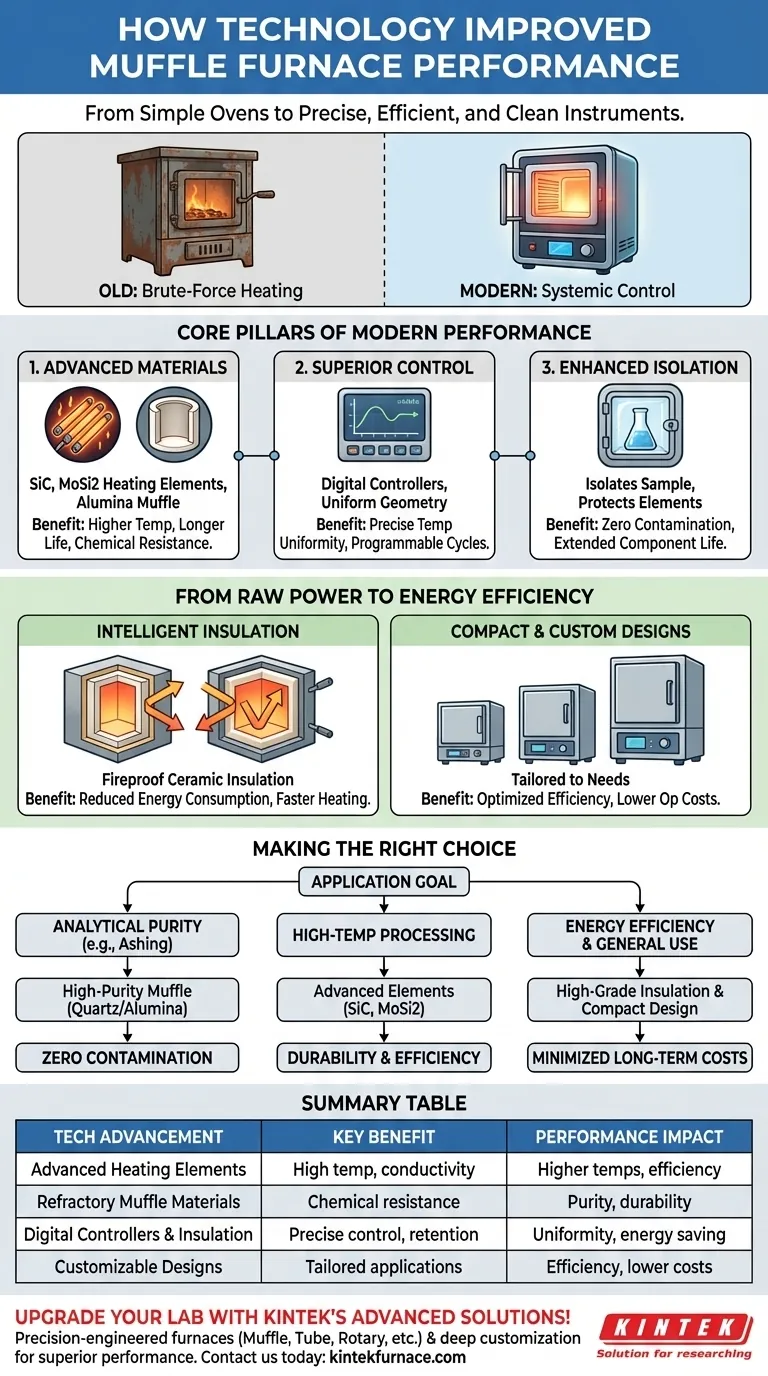

The Core Pillars of Modern Furnace Performance

The performance of a modern muffle furnace rests on a few key technological advancements that work together. Understanding these pillars is essential to appreciating their value in a lab or industrial setting.

Advanced Materials for Heating and Insulation

Older furnaces often used less durable components. Today, specialized materials are standard.

Heating elements are now frequently made from silicon carbide (SiC) or molybdenum disilicide (MoSi2). These materials have exceptionally high melting points and excellent thermal conductivity, allowing the furnace to reach and maintain high temperatures more efficiently and for longer service cycles.

The muffle itself—the inner chamber—is made from refractory materials like alumina. This provides outstanding chemical resistance and withstands repeated, rapid heating and cooling without degrading, ensuring a long and reliable service life.

Superior Temperature Control and Uniformity

Achieving an exact temperature is one thing; ensuring it is the same temperature everywhere inside the chamber is another.

The combination of advanced heating elements and the geometry of the muffle chamber creates an environment with excellent temperature uniformity. This is critical for processes like heat-treating or materials research, where even minor temperature deviations can ruin a sample or an entire batch.

This precision is managed by modern digital controllers, which allow for programmable heating cycles and tight control over the entire process.

Enhanced Chamber Isolation and Purity

The defining feature of a muffle furnace is the muffle itself. Its primary role is to create a barrier.

This muffle isolates the sample from the heating elements and any potential contaminants from combustion. This is non-negotiable for sensitive applications like ashing, where the purity of the final sample is paramount.

It also protects the heating elements from any vapors or gases released by the sample during heating, which significantly extends the life of these critical components.

From Raw Power to Energy Efficiency

Early furnaces consumed vast amounts of energy to maintain temperature. Modern designs prioritize efficiency without sacrificing performance.

The Role of Intelligent Insulation

Modern furnaces use high-grade, fireproof ceramic insulation. This material is engineered not just to contain heat but to do so with extreme efficiency.

Proper insulation dramatically reduces energy consumption by preventing heat from escaping the chamber. This means less power is required to maintain a set temperature.

A secondary benefit is a faster heating speed. By trapping thermal energy effectively, the chamber reaches its target temperature more quickly, reducing cycle times and further saving energy.

Compact and Customizable Designs

Technology has also enabled more flexible and compact designs.

Furnaces are no longer one-size-fits-all. They can be customized for specific laboratory or industrial needs, ensuring the equipment is perfectly suited for the task without being excessively large or power-hungry. This tailored approach inherently boosts efficiency.

Understanding the Trade-offs

While the benefits of modern technology are clear, they come with considerations.

Initial Cost vs. Total Cost of Ownership

Furnaces equipped with advanced materials like silicon carbide elements and high-purity alumina muffles typically have a higher upfront purchase price.

However, this initial investment is often offset over the furnace's lifespan. The reduced energy consumption, longer life of components, and lower maintenance needs result in a lower total cost of ownership.

Complexity and Application Matching

With more advanced features comes the need to match the furnace to the application correctly.

Purchasing a furnace with capabilities far beyond your needs (e.g., extremely high-temperature range or advanced atmospheric controls) can lead to unnecessary expense and complexity. The key is to identify the features that directly solve your specific problem.

Making the Right Choice for Your Application

Selecting the right furnace depends entirely on your primary goal.

- If your primary focus is analytical purity (e.g., ashing, trace metal analysis): Prioritize a furnace with a high-purity quartz or alumina muffle to ensure zero sample contamination.

- If your primary focus is high-temperature materials processing: Choose a model with silicon carbide (SiC) or molybdenum disilicide (MoSi2) heating elements for their durability and efficiency at extreme temperatures.

- If your primary focus is energy efficiency and general lab use: Look for models that explicitly advertise their high-grade ceramic insulation and compact design to minimize long-term operational costs.

Ultimately, understanding these technological advancements empowers you to choose a tool that is not just a heat source, but a precise instrument tailored to your work.

Summary Table:

| Technology Advancement | Key Benefit | Impact on Performance |

|---|---|---|

| Advanced Heating Elements (e.g., SiC, MoSi2) | High melting points, excellent thermal conductivity | Enables higher temperatures, longer service life, and efficient heating |

| Refractory Muffle Materials (e.g., alumina) | Chemical resistance, durability | Prevents contamination, withstands thermal cycling, ensures sample purity |

| Digital Controllers and Insulation | Precise temperature control, energy retention | Improves uniformity, reduces energy consumption, and speeds up heating cycles |

| Customizable Designs | Tailored to specific applications | Enhances efficiency, reduces operational costs, and fits diverse lab needs |

Upgrade your laboratory with KINTEK's advanced high-temperature furnace solutions! Leveraging exceptional R&D and in-house manufacturing, we provide diverse labs with precision-engineered products like Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures we meet your unique experimental requirements for superior performance, efficiency, and purity. Contact us today to discuss how we can enhance your processes and deliver reliable, cost-effective solutions tailored to your needs!

Visual Guide

Related Products

- 1400℃ Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- What is the primary function of a muffle furnace in iron-modified activated carbon prep? Optimize Adsorption Sites

- Why is re-calcination in a muffle furnace necessary for photocatalysts? Restore Efficiency via Thermal Oxidation

- What is the function of a muffle furnace in SiCf/Al-Mg pretreatment? Optimize Fiber Bonding with Thermal De-sizing

- What is the function of a muffle furnace during 500°C pre-calcination? Master CeZrPAl Support Synthesis

- What is the core role of a muffle furnace in the synthesis of calcium oxide from eggshells? Achieve High-Purity CaO