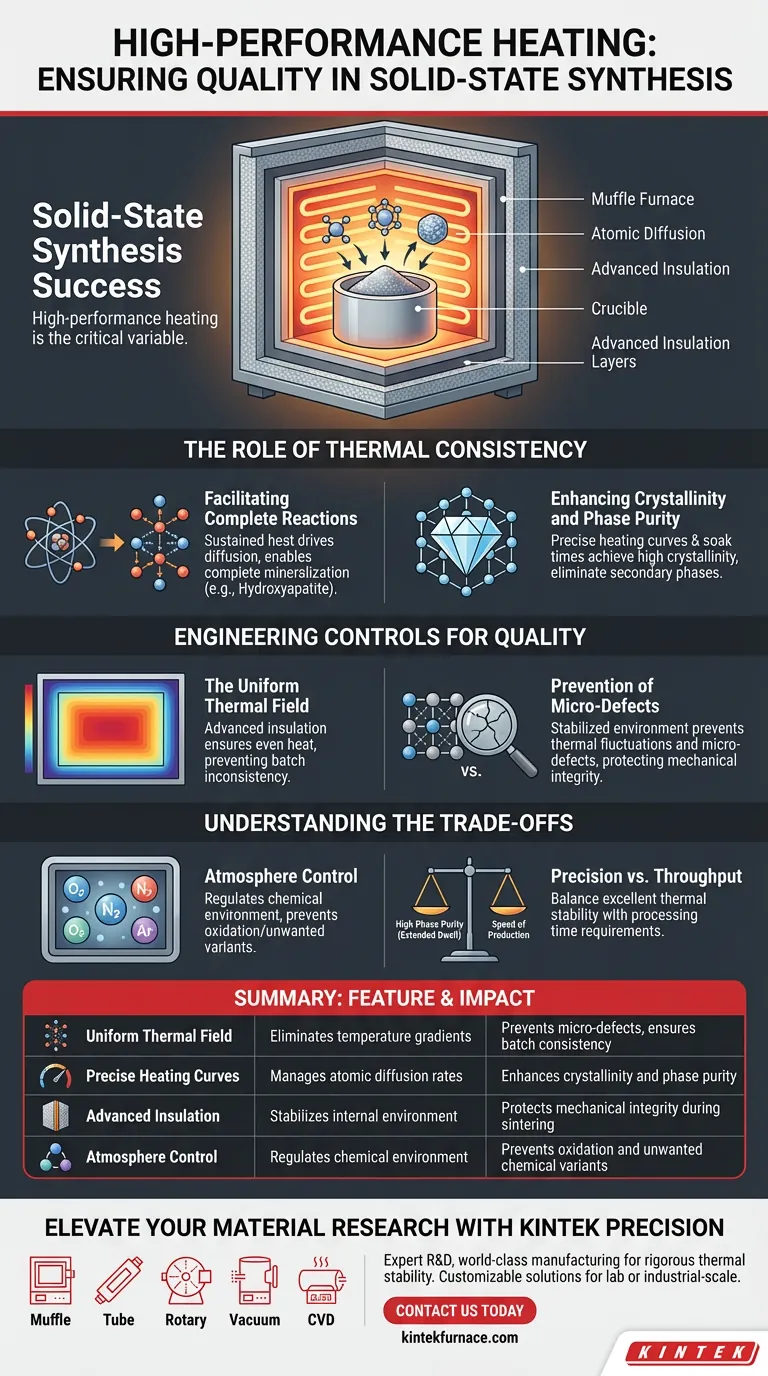

High-performance heating is the critical variable in solid-state synthesis success. A muffle furnace ensures quality by providing precise temperature programming and a strictly uniform thermal field. This controlled environment enables complete physical and chemical reactions while preventing micro-defects often caused by thermal fluctuations during sintering.

Success in solid-state synthesis relies on the ability to facilitate atomic diffusion without introducing structural faults. High-quality heating equipment ensures this by maintaining rigorous control over the heating curve and the reaction atmosphere, resulting in materials with high crystallinity and phase purity.

The Role of Thermal Consistency

Facilitating Complete Reactions

Solid-state synthesis relies heavily on sustained heat to drive diffusion between solid precursors. By maintaining a continuous high-temperature environment, furnaces facilitate the necessary chemical interaction between elements. For example, in hydroxyapatite synthesis, this consistent heat drives the reaction between calcium and phosphorus sources to achieve complete mineralization.

Enhancing Crystallinity and Phase Purity

The quality of the final crystal structure depends on how the heat is applied over time. High-performance equipment allows for the precise setting of heating curves and constant temperature durations. This controlled soak time is essential for achieving high crystallinity and eliminating unwanted secondary phases.

Engineering Controls for Quality

The Uniform Thermal Field

Temperature gradients within a furnace chamber can be disastrous for batch consistency. High-performance equipment uses advanced insulation to ensure the heat is distributed evenly throughout the chamber. This uniformity ensures that every part of the material undergoes the same thermal history.

Prevention of Micro-Defects

Fluctuations in temperature can cause physical stress and inconsistencies in the material. By stabilizing the environment during sintering or calcination, muffle furnaces prevent micro-defects. This strict regulation protects the mechanical integrity of the synthesized solid.

Understanding the Trade-offs

The Necessity of Atmosphere Control

While temperature is critical, thermal precision alone cannot guarantee quality if the chemical environment is ignored. Advanced muffle furnaces often include atmosphere control features. Without proper regulation of the atmosphere, materials may suffer from oxidation or unexpected chemical variants despite perfect temperature settings.

Precision vs. Throughput

Achieving high phase purity often requires extended dwell times and slow ramp rates. While this ensures a defect-free structure, it inherently limits the speed of production. Users must balance the need for excellent thermal stability with the practical requirements of processing time.

Making the Right Choice for Your Goal

To maximize the quality of your solid-state synthesis, align your equipment capabilities with your specific material requirements:

- If your primary focus is Phase Purity: Prioritize equipment with programmable heating curves to strictly control ramp rates and soak times for complete diffusion.

- If your primary focus is Structural Integrity: Ensure your furnace utilizes advanced insulation to maintain a uniform thermal field, minimizing the risk of micro-defects.

By mastering the thermal environment, you transform the furnace from a simple heating tool into an instrument of precise material engineering.

Summary Table:

| Feature | Impact on Synthesis | Key Benefit |

|---|---|---|

| Uniform Thermal Field | Eliminates temperature gradients | Prevents micro-defects & ensures batch consistency |

| Precise Heating Curves | Manages atomic diffusion rates | Enhances crystallinity and phase purity |

| Advanced Insulation | Stabilizes the internal environment | Protects mechanical integrity during sintering |

| Atmosphere Control | Regulates chemical environment | Prevents oxidation and unwanted chemical variants |

Elevate Your Material Research with KINTEK Precision

Don't let thermal fluctuations compromise your phase purity. At KINTEK, we understand that high-performance heating is the backbone of successful solid-state synthesis. Backed by expert R&D and world-class manufacturing, we provide high-precision Muffle, Tube, Rotary, Vacuum, and CVD systems designed to deliver the rigorous thermal stability your materials demand.

Whether you require customizable heating curves for specialized lab work or industrial-scale sintering, our high-temperature furnaces are engineered for your unique needs. Contact us today to discover how KINTEK’s customizable thermal solutions can optimize your synthesis process and ensure defect-free structural integrity.

Visual Guide

References

- Enhancing Vinyl Acetate Hydroformylation with La‐Decorated Rh/TiO<sub>2</sub> Nanotubes Catalysts. DOI: 10.1002/cphc.202401016

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- 1400℃ Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

People Also Ask

- What optional features are available for box furnaces? Customize for Your Lab's Unique Needs

- Why is the muffle furnace heat treatment necessary for NiCo2O4/ZnO-CuO/NF electrodes? Unlock High-Performance Activity

- What are the key characteristics of box type electric furnaces? Precision Heating for Labs and Industry

- What is the core function of a muffle furnace in CuO nanoparticle synthesis? Achieve Precision Calcination

- What role does an electric muffle furnace play in the siliconization of 10Kh23N18 steel welds? Expert Thermal Insight

- Why is a secondary annealing treatment in a muffle furnace necessary for coated ceramic sensor components?

- Why are muffle furnaces popular in industrial sectors? Discover Their Key Benefits for Clean, Precise Heating

- Which types of labs commonly use vacuum muffle furnaces? Essential for High-Purity Heat Treatment