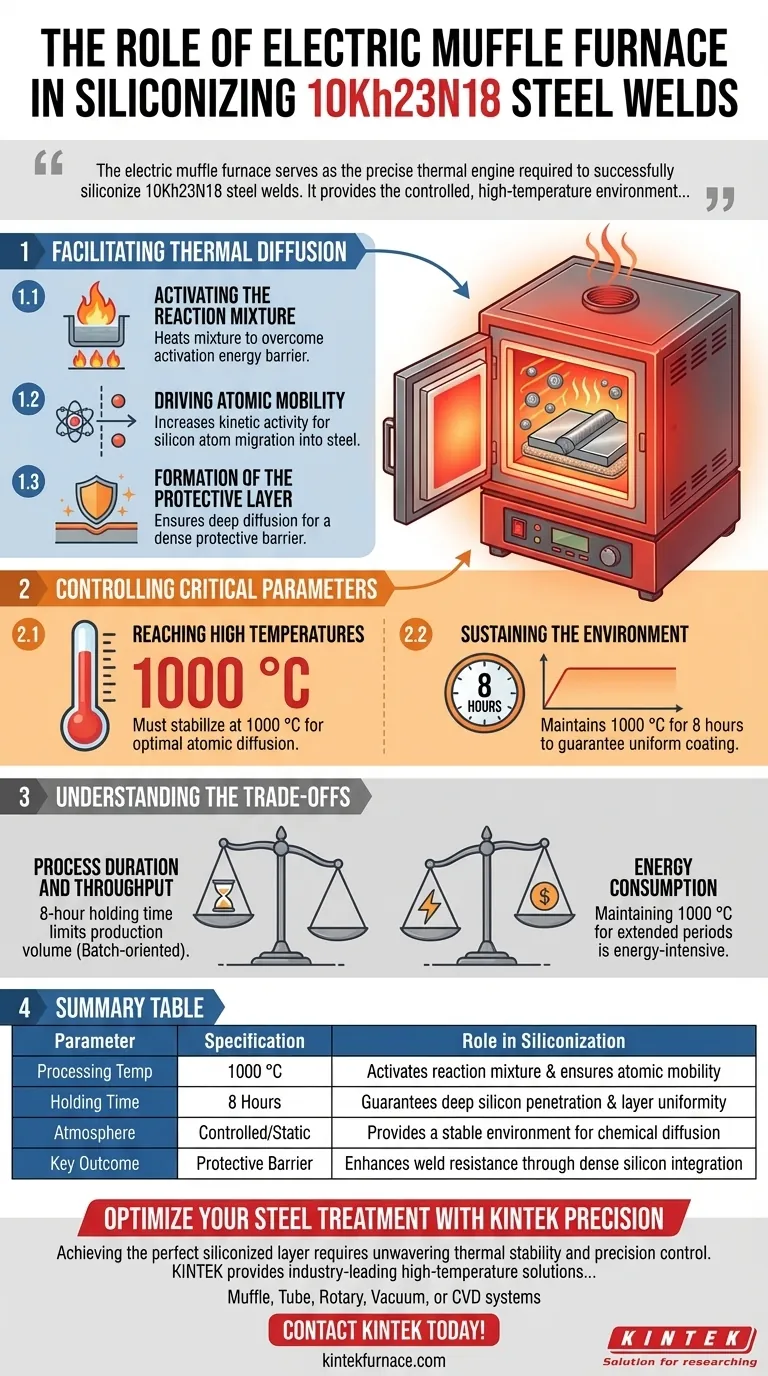

The electric muffle furnace serves as the precise thermal engine required to successfully siliconize 10Kh23N18 steel welds. It provides the controlled, high-temperature environment necessary to heat the reaction mixture and steel samples, driving the chemical and physical changes essential for the treatment.

The furnace creates the conditions for thermal diffusion, holding the material at 1000 °C for extended periods to ensure silicon atoms penetrate the weld structure and form a dense protective barrier.

Facilitating Thermal Diffusion

Activating the Reaction Mixture

Siliconization is not a passive process; it requires significant energy to initiate. The electric muffle furnace heats the reaction mixture surrounding the 10Kh23N18 steel, overcoming the activation energy barrier required for the chemical process to begin.

Driving Atomic Mobility

Once the appropriate temperature is reached, the furnace provides continuous thermal energy input. This energy increases the kinetic activity of the silicon atoms, allowing them to migrate from the mixture into the solid steel surface.

Formation of the Protective Layer

The ultimate goal of this thermal treatment is the creation of a dense protective layer. The furnace ensures that the diffusion is sufficient to integrate silicon deep enough into the weld structure to modify its surface properties effectively.

Controlling Critical Parameters

Reaching High Temperatures

The specific protocol for 10Kh23N18 steel requires extreme heat. The muffle furnace must be capable of reaching and stabilizing at 1000 °C, a temperature where the steel's lattice structure allows for optimal atomic diffusion.

Sustaining the Environment

Reaching temperature is not enough; the furnace must maintain it. The process requires a holding time of 8 hours, during which the furnace ensures the temperature does not fluctuate, guaranteeing a uniform coating.

Understanding the Trade-offs

Process Duration and Throughput

The requirement for an 8-hour holding time at 1000 °C represents a significant bottleneck in production. This extended cycle time limits the volume of parts that can be processed quickly, making it a batch-oriented rather than continuous operation.

Energy Consumption

Maintaing a chamber at 1000 °C for extended periods is energy-intensive. The operational cost of the muffle furnace is a primary factor in the overall expense of the siliconization process for these steel welds.

Making the Right Choice for Your Goal

To optimize the siliconization of 10Kh23N18 steel, consider your specific processing needs:

- If your primary focus is Layer Depth: Ensure your furnace can maintain the 1000 °C setpoint without fluctuation for the full 8-hour cycle to maximize diffusion.

- If your primary focus is Process Efficiency: Plan your batch sizes carefully, as the fixed heating and holding times make small-batch processing economically inefficient.

The electric muffle furnace is the indispensable tool that transforms raw thermal energy into the precise chemical driving force needed to protect steel welds.

Summary Table:

| Parameter | Specification | Role in Siliconization |

|---|---|---|

| Processing Temp | 1000 °C | Activates reaction mixture & ensures atomic mobility |

| Holding Time | 8 Hours | Guarantees deep silicon penetration & layer uniformity |

| Atmosphere | Controlled/Static | Provides a stable environment for chemical diffusion |

| Key Outcome | Protective Barrier | Enhances weld resistance through dense silicon integration |

Optimize Your Steel Treatment with KINTEK Precision

Achieving the perfect siliconized layer on 10Kh23N18 steel requires more than just heat—it requires unwavering thermal stability and precision control. KINTEK provides industry-leading high-temperature solutions backed by expert R&D and manufacturing.

Whether you need Muffle, Tube, Rotary, Vacuum, or CVD systems, our furnaces are fully customizable to meet your unique metallurgical demands. Don't let temperature fluctuations compromise your weld integrity.

Contact KINTEK today to discuss your project requirements!

Visual Guide

References

- Nikita V. Lemeshko, Ruslan M. Tazetdinov. Production of silicon-based thermodiffusion layer in tube furnace coil weld after long-term operation. DOI: 10.1051/epjconf/202531801007

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1400℃ Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

People Also Ask

- What factors affect the price of muffle furnaces? Key Drivers for Smart Lab Investment

- What applications do box type resistance furnaces have in ceramics and glass processing? Essential for Sintering and Hot Bending

- What are the applications of a laboratory muffle furnace in biochar evaluation? Optimize Your Biomass Research

- What are the advantages of a muffle furnace? Achieve Unmatched Thermal Control and Purity

- What role does a muffle furnace play in BCZY712 electrolyte powder production? Achieve Perfect Phase Purity

- Why is insulation quality important in muffle furnaces? Boost Efficiency and Safety in Your Lab

- How does a muffle furnace function and what is its primary purpose? Discover Precision Heating for Pure Results

- How does a high-temperature heating furnace facilitate the homogenization of shipbuilding steel? Achieve Peak Uniformity