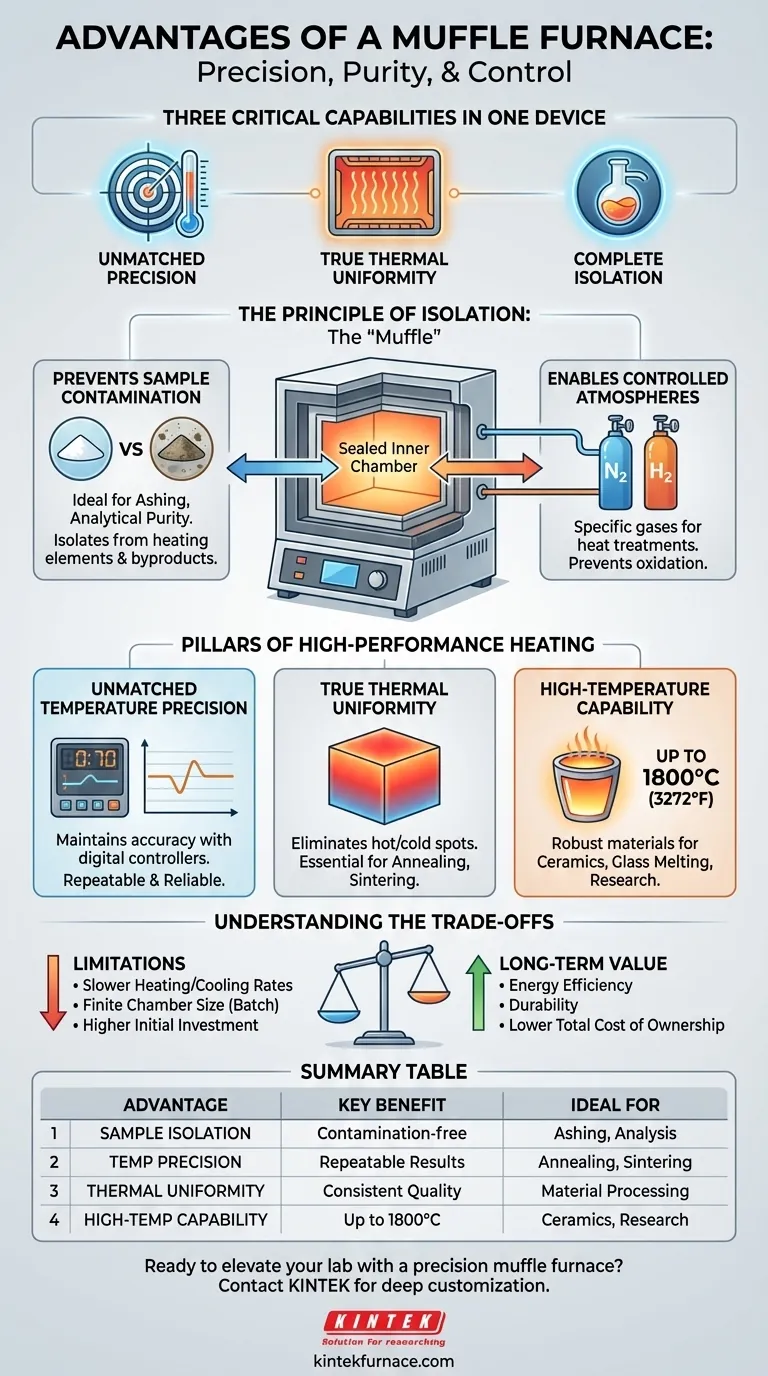

At its core, a muffle furnace excels by providing three critical capabilities in a single device: exceptionally precise temperature control, highly uniform heating, and complete isolation of the sample from environmental contaminants. This unique combination makes it an indispensable tool for sensitive scientific analysis and advanced materials processing where the integrity of the sample and the consistency of the result are paramount.

The primary advantage of a muffle furnace stems from its core design—a sealed inner chamber, or "muffle." This chamber isolates the material being heated from the raw energy source, delivering a pure, stable, and uniformly controlled thermal environment that is impossible to achieve with conventional ovens or direct-flame furnaces.

The Principle of Isolation: Why the "Muffle" Matters

The defining feature of a muffle furnace is the muffle itself—an isolated retort or chamber, traditionally made of refractory ceramic materials. This design is the source of its most important benefits.

Preventing Sample Contamination

The sealed chamber separates the sample from the heating elements and, in fuel-fired models, from the byproducts of combustion.

This isolation is non-negotiable for applications like ashing, where the goal is to burn off organic material to precisely measure the non-combustible content. Any external contaminants would corrupt the final measurement.

Enabling Controlled Atmospheres

Because the chamber is sealed from the outside environment, you can often control the atmosphere within it.

This allows for processes that require specific gases, such as performing heat treatments in an inert atmosphere of nitrogen or a reducing atmosphere of hydrogen to prevent oxidation.

The Pillars of High-Performance Heating

The isolated, insulated design directly enables superior thermal performance that defines the furnace's capabilities in a lab or production setting.

Unmatched Temperature Precision

Modern muffle furnaces use digital controllers that work in tandem with the insulated chamber to maintain temperature with incredible accuracy.

This stability is critical for thermal processes with narrow windows for success, ensuring that results are repeatable and reliable.

Achieving True Thermal Uniformity

The enclosed chamber is engineered to distribute heat evenly, eliminating hot and cold spots. This ensures the entire sample experiences the same temperature at the same time.

Thermal uniformity is essential for processes like annealing metals to relieve internal stresses or sintering powders into a solid mass, where inconsistent heating would ruin the material's structural integrity.

High-Temperature Capability

Constructed from robust, heat-resistant materials and high-performance insulation, muffle furnaces are built to operate reliably at extreme temperatures, often up to 1800°C (3272°F).

This capability makes them suitable for treating ceramics, melting glass, and performing high-temperature materials research.

Understanding the Trade-offs

While powerful, a muffle furnace is not the universal solution for all heating tasks. Understanding its limitations is key to using it effectively.

Heating and Cooling Rates

The same insulation that makes the furnace efficient also means it heats up and cools down relatively slowly compared to direct heating methods. For processes requiring rapid thermal cycling, this can be a limitation.

Chamber Size and Throughput

Muffle furnaces are typically designed for batch processes and have a finite chamber volume. They are not ideal for continuous processing or for heating very large or irregularly shaped objects that won't fit within the chamber.

Initial Investment

A high-performance muffle furnace represents a greater upfront cost than a simple laboratory oven or a basic forge. However, its energy efficiency, durability, and long service life often result in a lower total cost of ownership over time.

Making the Right Choice for Your Process

Your specific goal determines which advantage of a muffle furnace is most valuable to you.

- If your primary focus is analytical purity (e.g., ashing or materials analysis): The contamination-free environment provided by the sealed muffle is its single most critical feature.

- If your primary focus is material quality (e.g., annealing or sintering): Its exceptional thermal uniformity and precise temperature control are what guarantee consistent, high-quality results.

- If your primary focus is versatile, high-temperature work: Its safety, durability, and ability to handle diverse processes make it a foundational workhorse for any advanced lab or workshop.

Ultimately, a muffle furnace is the definitive tool when your process demands absolute control over the thermal environment.

Summary Table:

| Advantage | Key Benefit | Ideal For |

|---|---|---|

| Sample Isolation | Contamination-free environment | Ashing, materials analysis |

| Temperature Precision | Repeatable, reliable results | Annealing, sintering |

| Thermal Uniformity | Eliminates hot/cold spots | High-quality material processing |

| High-Temperature Capability | Operates up to 1800°C | Ceramics, glass melting, research |

Ready to elevate your lab's capabilities with a precision muffle furnace?

At KINTEK, we understand that your research demands absolute thermal control and purity. Our advanced muffle furnaces are engineered with exceptional R&D and in-house manufacturing to deliver the precise temperature stability, uniform heating, and contamination-free environment your sensitive processes require.

Whether you are working in materials analysis, annealing, sintering, or high-temperature research, our deep customization capabilities ensure your furnace is tailored to your unique experimental needs.

Contact our experts today to discuss how a KINTEK muffle furnace can become the definitive tool for your lab.

Visual Guide

Related Products

- 1400℃ Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- How does the use of a 100-mesh sieve contribute to the performance consistency of magnetic chitosan carbon?

- What is the core function of a muffle furnace in CuO nanoparticle synthesis? Achieve Precision Calcination

- What is the purpose of heating a precursor solution to 80 °C and 300 rpm stirring? Achieve High-Entropy Uniformity

- What is the function of a muffle furnace in SiCf/Al-Mg pretreatment? Optimize Fiber Bonding with Thermal De-sizing

- What is the primary function of a high-temperature box resistance furnace? Optimize Superalloy Homogenization