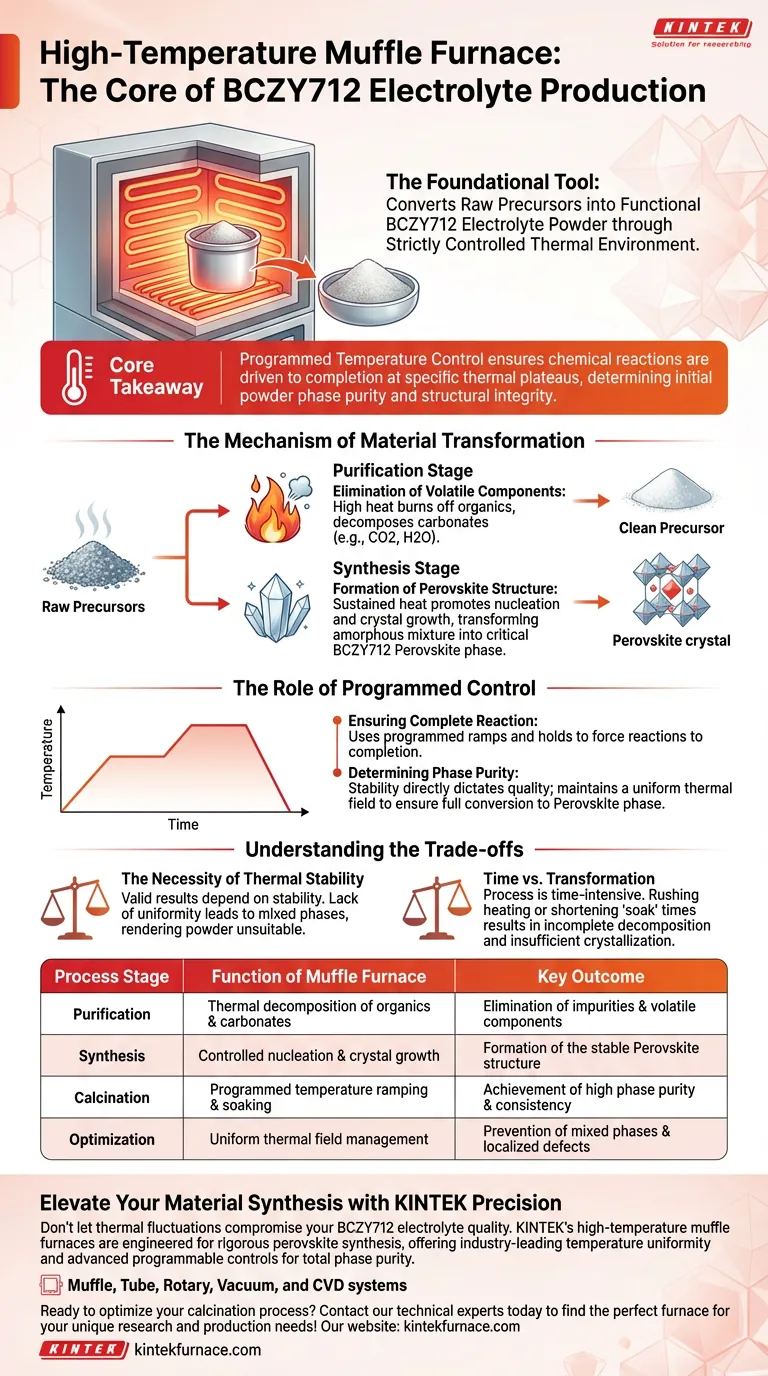

A high-temperature muffle furnace serves as the foundational processing tool for converting raw chemical precursors into functional BCZY712 electrolyte powder. It creates a strictly controlled thermal environment that drives the removal of organic impurities and carbonates while simultaneously facilitating the nucleation and growth of the critical perovskite crystal phase.

Core Takeaway The muffle furnace utilizes programmed temperature control to ensure that chemical reactions are driven to completion at specific thermal plateaus. This precise thermal management is the primary determinant of the initial powder's phase purity and structural integrity.

The Mechanism of Material Transformation

Elimination of Volatile Components

The initial stage of the calcination process involves purification. The muffle furnace provides the high heat necessary to burn off organic components inherent in the precursor mix.

Simultaneously, the thermal energy drives the decomposition of carbonates. Removing these elements is essential, as their presence would compromise the chemical composition of the final electrolyte.

Formation of the Perovskite Structure

Once impurities are removed, the furnace facilitates the actual synthesis of the material. The sustained heat promotes nucleation, the process where the initial crystal structure begins to form.

Following nucleation, the thermal environment supports crystal growth. This transforms the amorphous mixture into the specific perovskite crystal phase required for BCZY712 to function effectively as an electrolyte.

The Role of Programmed Control

Ensuring Complete Reaction

Success in calcination relies on more than just high heat; it requires a specific thermal profile. The muffle furnace uses programmed temperature control to ramp up and hold temperatures at preset intervals.

This automation ensures that the material spends exactly enough time at the required temperatures to force the chemical reactions to completion.

Determining Phase Purity

The stability provided by the furnace directly dictates the quality of the output. The phase purity of the BCZY712 powder is a direct result of the furnace's ability to maintain a stable, uniform thermal field.

If the thermal environment fluctuates, the conversion to the perovskite phase may be partial, resulting in an inferior product with inconsistent electrical properties.

Understanding the Trade-offs

The Necessity of Thermal Stability

While high temperatures are required, valid results depend entirely on stability. A furnace that cannot maintain a uniform thermal field (as mentioned in broader industrial contexts) risks creating localized hotspots or cool zones.

This lack of uniformity can lead to mixed phases within the same batch, rendering the powder unsuitable for high-performance electrolyte applications.

Time vs. Transformation

The process is inherently time-intensive. Achieving a complete reaction and proper crystal growth requires strict adherence to the programmed schedule.

Rushing the heating rates or shortening the "soak" times at maximum temperature will result in incomplete decomposition of precursors or insufficient crystallization.

Making the Right Choice for Your Goal

To ensure the successful production of BCZY712 powder, you must align the furnace's capabilities with your specific processing metrics.

- If your primary focus is Phase Purity: Prioritize a furnace with high-precision temperature stability and uniform heating zones to ensure the entire batch achieves the perovskite structure.

- If your primary focus is Process Consistency: Rely on units with advanced programmable controls that allow for repeatable, automated ramping and soaking schedules to eliminate operator error.

The quality of your BCZY712 electrolyte is ultimately defined by the precision of the thermal environment in which it is born.

Summary Table:

| Process Stage | Function of Muffle Furnace | Key Outcome |

|---|---|---|

| Purification | Thermal decomposition of organics & carbonates | Elimination of impurities & volatile components |

| Synthesis | Controlled nucleation & crystal growth | Formation of the stable Perovskite structure |

| Calcination | Programmed temperature ramping & soaking | Achievement of high phase purity & consistency |

| Optimization | Uniform thermal field management | Prevention of mixed phases & localized defects |

Elevate Your Material Synthesis with KINTEK Precision

Don’t let thermal fluctuations compromise your BCZY712 electrolyte quality. KINTEK’s high-temperature muffle furnaces are engineered for the rigorous demands of perovskite synthesis, offering the industry-leading temperature uniformity and advanced programmable controls necessary for total phase purity.

Backed by expert R&D and world-class manufacturing, we provide a full range of customizable solutions including Muffle, Tube, Rotary, Vacuum, and CVD systems designed specifically for lab-scale and industrial high-temp applications.

Ready to optimize your calcination process? Contact our technical experts today to find the perfect furnace for your unique research and production needs!

Visual Guide

References

- Pallavi Bhaktapralhad Jagdale, Manav Saxena. Agri-waste derived electroactive carbon–iron oxide nanocomposite for oxygen reduction reaction: an experimental and theoretical study. DOI: 10.1039/d4ra01264j

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1400℃ Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

People Also Ask

- What role does a high-temperature box furnace play in the secondary sintering and structural repair of recycled NCM?

- What is the application of a Muffle Furnace in biochar characterization? Master Ash Analysis & Pyrolysis Control

- How has technology improved muffle furnace performance? Achieve Precision, Efficiency, and Purity in Heating

- What should be done before using a muffle furnace for the first time or after a long period of inactivity? Essential Pre-Baking Guide

- Why is a laboratory box resistance furnace used for mango seed drying kinetics? Achieve Precise Isothermal Control

- Why is precise temperature control in a muffle furnace essential during the secondary calcination of acid-etched catalysts?

- What is the function of a muffle furnace in Li2Mg3Ti(1-x)ZrxO6 calcination? Optimize Ceramic Phase Purity

- What specialized processes can a box furnace facilitate? Unlock Precision Material Transformation