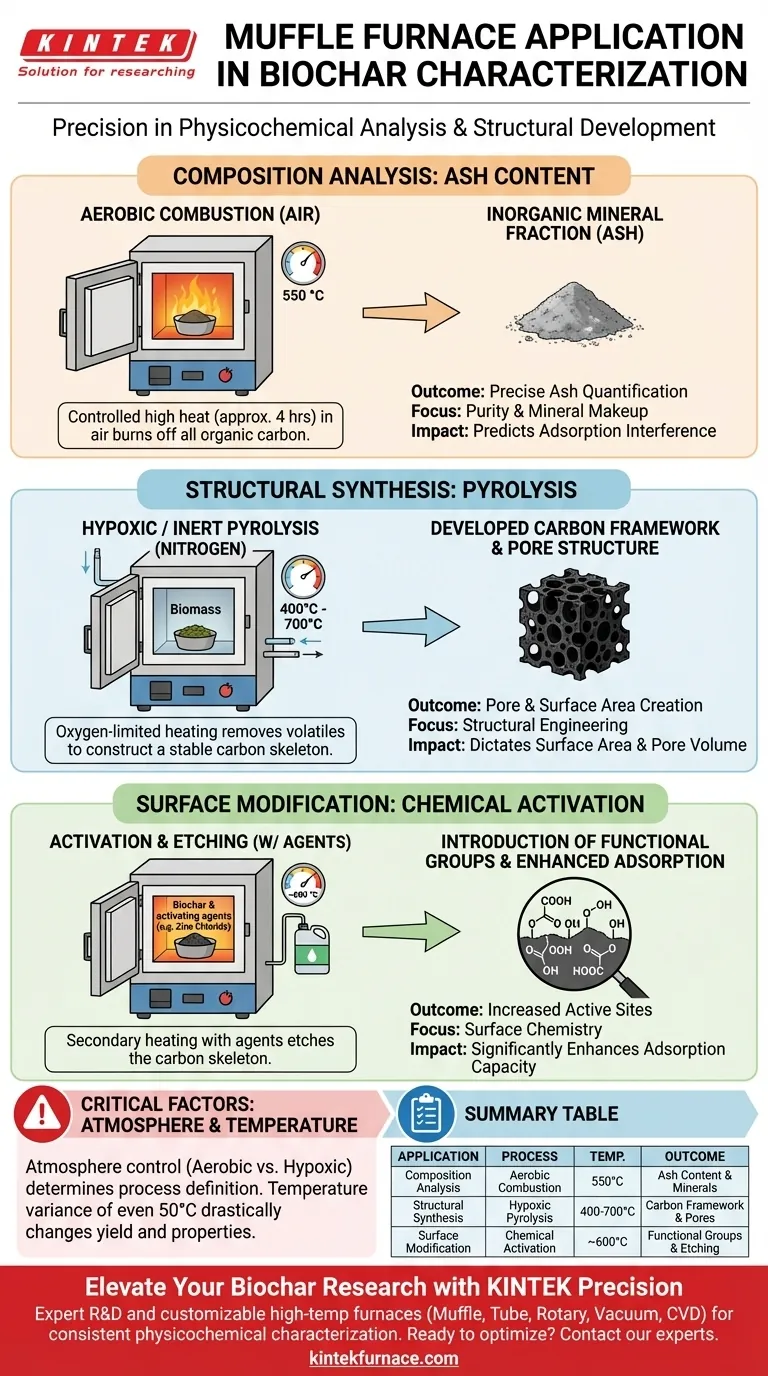

The primary application of a Muffle Furnace in the physicochemical characterization of biochar is the precise determination of ash content.

By subjecting samples to controlled high temperatures—typically 550 °C for extended periods—the furnace ensures the complete combustion of organic matter. This leaves behind only the inorganic mineral components, allowing for the accurate quantification of non-carbon elements that influence the material's adsorption performance.

Core Takeaway While widely used for material synthesis, in the context of characterization, the muffle furnace acts as a critical gravimetric tool. It isolates the inorganic fraction of the biomass by burning off the carbon skeleton, providing essential data on purity and mineral composition that dictates the biochar's final application efficiency.

Characterizing Inorganic Composition: Ash Content

The most direct analytical use of the muffle furnace is evaluating the purity and mineral makeup of the raw material and the final biochar product.

The Combustion Process

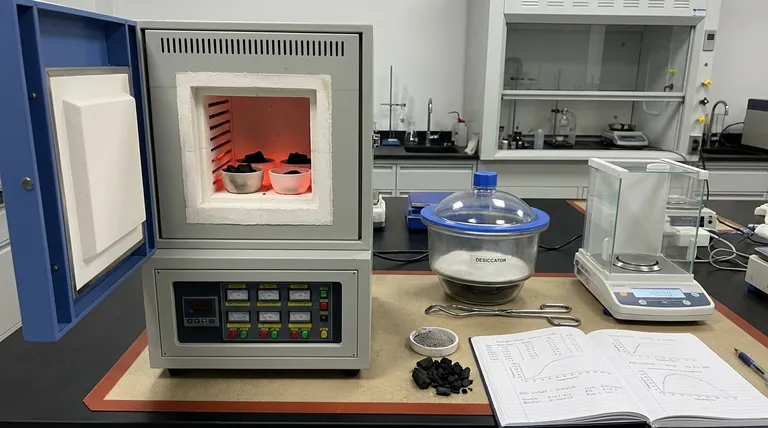

To determine ash content, the furnace is set to an aerobic environment to facilitate oxidation. Samples are heated to approximately 550 °C for a duration of roughly 4 hours.

Isolation of Minerals

This intense heat removes all organic carbon and volatile matter. The remaining residue represents the inorganic minerals (ash), which allows researchers to calculate the exact percentage of non-combustible material in the sample.

Impact on Adsorption

Understanding ash content is vital because inorganic components can block pores or chemically interact with adsorbates. Accurate characterization here predicts how well the biochar will perform in filtration or soil amendment applications.

Sample Preparation and Structural Development

While ash determination is an analytical process, the muffle furnace is also the primary tool for preparing samples with specific physicochemical properties to be characterized.

Controlled Pyrolysis

Unlike ash determination, this process requires an oxygen-limited (hypoxic) or nitrogen-rich atmosphere. The furnace heats biomass (such as cotton waste, Miscanthus, or date stones) to temperatures between 400 °C and 700 °C.

Developing the Carbon Framework

By restricting oxygen, the furnace prevents the sample from turning to ash. Instead, it facilitates thermal decomposition, removing volatiles to construct a stable carbon skeleton.

Pore Structure Formation

This thermal treatment is responsible for the initial development of the material's porosity. The specific temperature and duration (e.g., 600 °C for 30 minutes) dictate the surface area and pore volume, which are subsequently measured during characterization.

Advanced Chemical Modification

The muffle furnace is also utilized in secondary thermal stages to chemically alter the biochar's surface properties for specialized characterization.

Activation and Etching

Researchers use the furnace to heat biochar with activating agents, such as zinc chloride, often at temperatures around 600 °C. This process acts as a dehydrating step that "etches" the carbon skeleton.

Functionalization

This deep modification increases the specific surface area and introduces active nanoparticles (like Zinc Oxide). This creates specific surface functional groups that significantly enhance the material's adsorption capacity.

Understanding the Trade-offs

Using a muffle furnace requires distinguishing between analytical combustion and structural synthesis.

Atmosphere Control is Critical

The definition of the process changes entirely based on gas flow. Aerobic conditions destroy the carbon structure (Ash Content), while hypoxic/inert conditions preserve and harden it (Pyrolysis). Failing to seal a retort or control nitrogen flow during synthesis will result in unwanted ash rather than biochar.

Temperature Precision

Temperature deviations significantly alter physicochemical data. A variance of even 50 °C during the preparation phase can drastically change the yield, pore size distribution, and surface functional groups, making consistent characterization impossible.

Making the Right Choice for Your Goal

The muffle furnace is a dual-purpose instrument in biochar science. To use it effectively, clearly define your immediate objective.

- If your primary focus is Composition Analysis: Use the furnace to perform complete combustion at 550 °C in air to quantify inorganic ash content.

- If your primary focus is Structural Engineering: Use the furnace to drive pyrolysis at 400–700 °C in an oxygen-limited environment to build pore structure and surface area.

- If your primary focus is Surface Activation: Use the furnace for a secondary heating stage with chemical agents to introduce functional groups and etch the carbon surface.

Used correctly, the muffle furnace serves as the foundational tool for both defining the structure of biochar and verifying its chemical purity.

Summary Table:

| Application Category | Primary Process | Typical Temperature | Key Outcome/Data |

|---|---|---|---|

| Composition Analysis | Aerobic Combustion | 550°C | Precise determination of Ash Content & Mineral Fraction |

| Structural Synthesis | Hypoxic Pyrolysis | 400°C - 700°C | Development of carbon framework and pore structure |

| Surface Modification | Chemical Activation | ~600°C | Introduction of functional groups and surface area etching |

Elevate Your Biochar Research with KINTEK Precision

Consistency is the backbone of accurate physicochemical characterization. At KINTEK, we understand that a variance of even 50°C can compromise your entire data set. Backed by expert R&D and manufacturing, KINTEK offers Muffle, Tube, Rotary, Vacuum, and CVD systems, all fully customizable for your unique lab needs.

Whether you are quantifying ash content or engineering complex carbon frameworks, our high-temp furnaces provide the thermal stability and atmosphere control required for industry-leading results.

Ready to optimize your thermal processes?

Contact our experts today to find your custom solution.

Visual Guide

References

- S. S. Ibrahim, Badr A. Mohamed. Catalyzed biochar from date palm waste for ammonium removal: potential application in poultry farms for ammonia mitigation. DOI: 10.1007/s43621-025-00817-6

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1400℃ Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

People Also Ask

- Why is indirect heating important in muffle furnaces? Ensure Purity and Precision in High-Temp Processes

- What industrial applications do muffle furnaces have in heat treating? Precision Solutions for High-Tech Industries

- What are the primary functions of muffle furnaces? Achieve Clean, Uniform Heating for Your Materials

- What role does a high-temperature box resistance furnace play in Hydroxyapatite/Zirconia composite preparation?

- How do high-vacuum muffle furnaces or tube furnaces facilitate the activation of materials like UiO-66-NH2?

- What role does a muffle furnace play in the synthesis of carbon nitride? Master Thermal Polycondensation Control

- What role does a high-temperature box resistance furnace play in sintering? Mastering Electrolyte Tube Densification

- What is a muffle furnace and what temperature range can it reach? Discover High-Temp Solutions