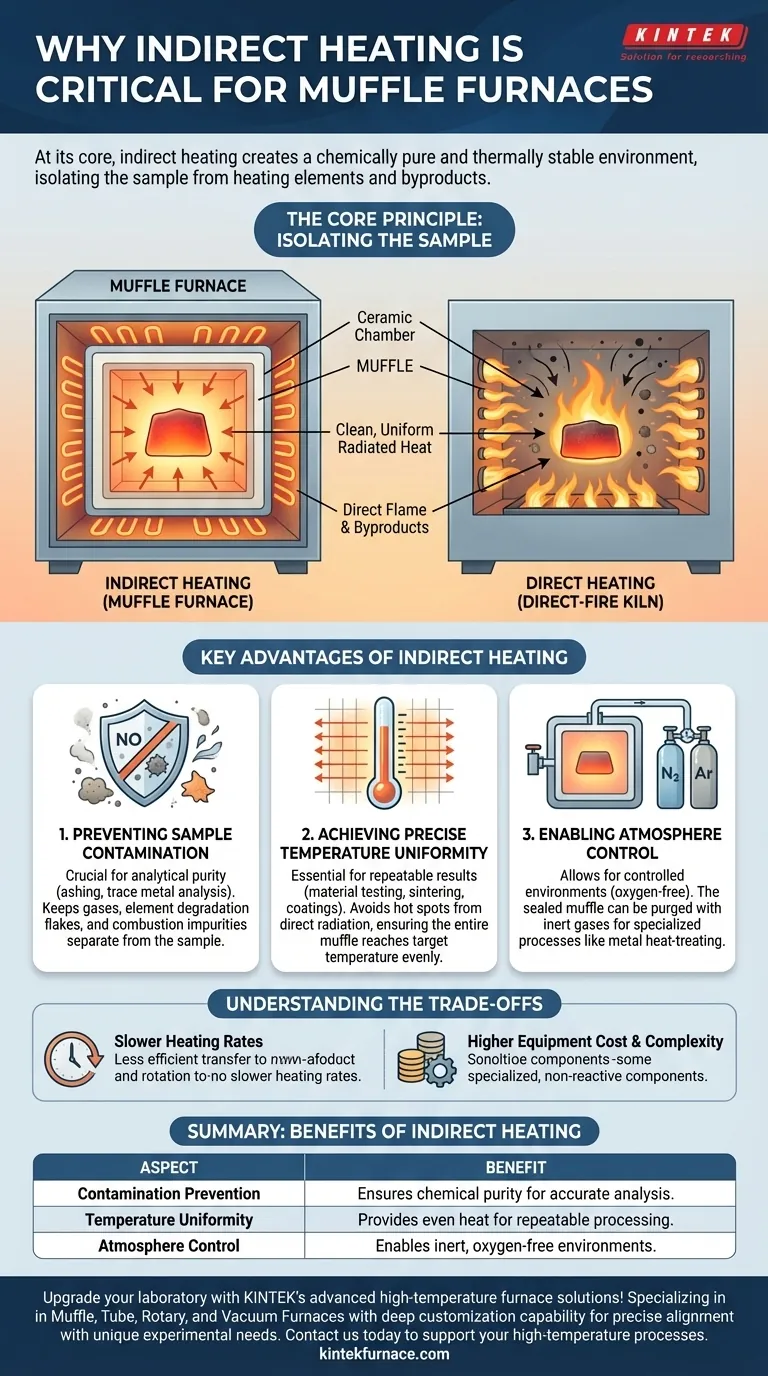

At its core, the importance of indirect heating in a muffle furnace is to create a chemically pure and thermally stable environment. By placing the sample inside a "muffle"—a separate, isolated chamber—the heating elements and any combustion byproducts are kept entirely separate from the material being processed. This separation is what enables the precision, purity, and control required for sensitive scientific and industrial applications.

The fundamental purpose of a muffle furnace is not just to heat a sample, but to do so without altering its chemical composition. Indirect heating is the critical design feature that makes this possible by creating an isolated and controllable processing environment.

The Core Principle: Isolating the Sample

The name "muffle furnace" describes its key function. The design is centered around a retort, or muffle, that isolates the workload from the raw energy source.

What is a "Muffle"?

A muffle is a sealed chamber, typically made of high-temperature ceramic or alloy, that sits inside the furnace's insulated shell.

Heating elements are positioned outside this muffle, heating its external walls. The heat then radiates uniformly into the chamber's interior, creating a stable thermal environment for the sample placed inside.

Indirect vs. Direct Heating: A Key Distinction

Think of a muffle furnace like a modern convection oven, where the heating elements are separate from the food. The goal is clean, uniform heat.

A direct-fire kiln or forge, by contrast, is like cooking over an open flame. While effective for raw heating, the flame and its byproducts (like soot or gases) directly interact with the object, which is unacceptable for high-purity work.

Key Advantages of Indirect Heating

This separation of sample from heat source provides three critical advantages that are non-negotiable in many technical fields.

Preventing Sample Contamination

For processes like determining the ash content of a material (ashing) or conducting trace metal analysis, any external contamination invalidates the result.

Indirect heating ensures that gases, flakes from degrading heating elements, or other impurities from the combustion process cannot enter the chamber and alter the sample's mass or chemical makeup.

Achieving Precise Temperature Uniformity

Heating elements inherently have hot spots. By placing them outside the muffle, their direct, uneven radiation does not hit the sample.

Instead, the entire muffle chamber slowly and evenly reaches the target temperature. This thermal uniformity is essential for repeatable material testing, sintering ceramics, and creating consistent coatings, where precise temperature profiles are paramount.

Enabling Atmosphere Control

Because the muffle is a sealed chamber, the atmosphere inside it can be controlled. This is impossible in a direct-fired system.

The chamber can be purged with an inert gas like nitrogen or argon to create an oxygen-free environment. This is crucial for heat-treating metals without oxidation or synthesizing materials that are sensitive to air.

Understanding the Trade-offs

While essential for precision, the indirect heating method comes with practical trade-offs that are important to acknowledge.

Slower Heating Rates

Heating the muffle chamber first, which then radiates heat to the sample, is a less efficient thermal transfer process. This means muffle furnaces typically have slower heat-up and cool-down times compared to direct-fire kilns.

Higher Equipment Cost and Complexity

The inclusion of a high-quality, non-reactive muffle and the systems to control its atmosphere add to the furnace's complexity and overall cost. These are specialized instruments, not simple heating ovens.

Making the Right Choice for Your Goal

Selecting the right furnace depends entirely on the requirements of your process.

- If your primary focus is analytical purity (ashing, composition analysis): The indirect heating of a muffle furnace is mandatory to prevent contamination and ensure accurate results.

- If your primary focus is controlled material processing (annealing metals, sintering ceramics, growing crystals): A muffle furnace is necessary for its precise temperature uniformity and atmosphere control.

- If your primary focus is simple bulk heating (drying, basic heat-treating where oxidation is not a concern): A less expensive, direct-fire oven or kiln may be a more efficient and cost-effective solution.

Ultimately, the use of indirect heating is what elevates a furnace from a simple oven to a precise instrument for scientific discovery and advanced manufacturing.

Summary Table:

| Aspect | Benefit of Indirect Heating |

|---|---|

| Contamination Prevention | Keeps heating elements and byproducts separate from samples, ensuring chemical purity for accurate analysis. |

| Temperature Uniformity | Provides even heat distribution, essential for repeatable material testing and processing. |

| Atmosphere Control | Allows use of inert gases to create oxygen-free environments, preventing oxidation in sensitive applications. |

Upgrade your laboratory with KINTEK's advanced high-temperature furnace solutions! Leveraging exceptional R&D and in-house manufacturing, we offer Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures precise alignment with your unique experimental needs, delivering enhanced purity, control, and efficiency. Don't compromise on quality—contact us today to discuss how we can support your high-temperature processes!

Visual Guide

Related Products

- 1400℃ Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- How does the use of a 100-mesh sieve contribute to the performance consistency of magnetic chitosan carbon?

- What is the purpose of heating a precursor solution to 80 °C and 300 rpm stirring? Achieve High-Entropy Uniformity

- What is the primary function of a high-temperature box resistance furnace? Optimize Superalloy Homogenization

- What is the core function of a muffle furnace in CuO nanoparticle synthesis? Achieve Precision Calcination

- What is the core role of a muffle furnace in the synthesis of calcium oxide from eggshells? Achieve High-Purity CaO