At its core, a muffle furnace is designed for one primary purpose: to heat materials to extremely high temperatures within a completely isolated chamber. This ensures the material is processed with exceptional temperature uniformity and is protected from all contaminants, including the byproducts of combustion that would be present in a traditional furnace.

The defining function of a muffle furnace is not just to generate heat, but to provide clean, uniform, and precisely controlled heat. The "muffle," or inner chamber, isolates the material, making it the indispensable tool for applications where purity and consistency are non-negotiable.

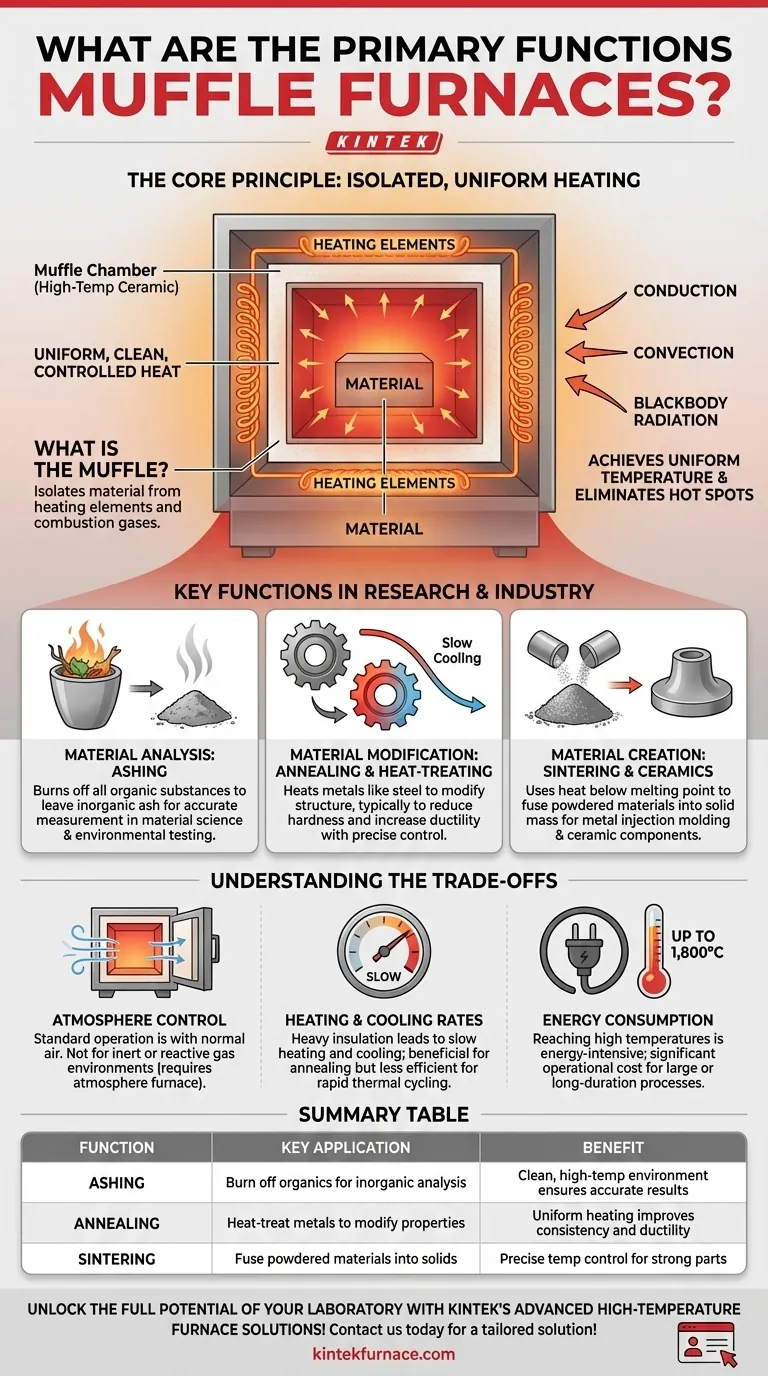

The Core Principle: Isolated, Uniform Heating

To understand the functions of a muffle furnace, you must first understand its fundamental design principle. Unlike other ovens, it separates the material being heated from the heat source itself.

What is the "Muffle"?

The term muffle refers to the furnace's inner chamber, which is typically constructed from high-temperature, heat-resistant ceramics.

This chamber contains the material but is sealed off from the actual heating elements. Heat is transferred through the walls of the muffle to the material inside.

How It Achieves Uniform Temperature

Modern electric muffle furnaces rely on a combination of heating methods to ensure the temperature is even throughout the entire chamber.

These methods include conduction, convection, and most importantly at high temperatures, blackbody radiation. This multi-faceted approach eliminates hot spots and ensures the entire workpiece receives the same thermal treatment.

The Benefit of a Contaminant-Free Environment

By isolating the sample from the heating elements, a muffle furnace prevents any contamination. In electric models, this means no exposure to combustion gases, flames, or fuel byproducts.

This clean environment is critical for sensitive chemical analyses and for processing materials whose properties would be altered by impurities.

Key Functions in Research and Industry

The unique capabilities of a muffle furnace make it a vital tool across a range of scientific and industrial applications.

Material Analysis: Ashing

One of the most common laboratory functions is ashing. This process involves heating a sample to burn off all organic substances, leaving only the inorganic ash content behind.

Because the muffle furnace provides a clean, high-temperature environment, it ensures an accurate measurement of the non-combustible material, which is critical in fields like materials science, food science, and environmental testing.

Material Modification: Annealing and Heat-Treating

Muffle furnaces are widely used for heat-treating metals like steel and copper. Processes like annealing involve heating a metal to a specific temperature and then cooling it slowly.

This modifies the metal's internal structure, typically to reduce hardness and increase ductility. The precise temperature control and uniformity of a muffle furnace are essential for achieving consistent, predictable results.

Material Creation: Sintering and Ceramics

Sintering is a process that uses heat to fuse powdered materials—such as metals or ceramics—into a solid mass without melting them.

The muffle furnace's ability to hold a precise temperature just below the material's melting point is crucial for applications like metal injection molding (MIM) and creating durable ceramic components. It is also fundamental in glass manufacturing.

Understanding the Trade-offs

While powerful, a muffle furnace is a specialized tool with inherent limitations that you must consider.

Atmosphere Control

A standard muffle furnace operates with a normal air atmosphere inside the chamber. While this is ideal for many processes, it is not suitable for applications that require an inert or reactive gas environment to prevent oxidation.

For those needs, a more specialized atmosphere furnace would be required.

Heating and Cooling Rates

The heavy insulation required to reach and maintain high temperatures means that muffle furnaces generally heat up and cool down slowly.

This characteristic is beneficial for processes like annealing but makes them less efficient for applications demanding rapid thermal cycling.

Energy Consumption

Achieving temperatures up to 1,800°C (3,272°F) is an energy-intensive process. The operational cost, particularly for large industrial units or long-duration processes, is a significant practical consideration.

Making the Right Choice for Your Application

Selecting the right heating instrument depends entirely on your end goal. A muffle furnace excels where control, cleanliness, and uniformity are paramount.

- If your primary focus is determining the inorganic content of a sample: A muffle furnace is the industry standard for ashing due to its clean, controlled, high-temperature environment.

- If your primary focus is modifying the properties of materials like metals: Its uniform heating makes it ideal for annealing and other heat treatments where consistency across the entire part is critical.

- If your primary focus is creating solid parts from powdered materials: The furnace's ability to hold precise temperatures below a material's melting point is essential for sintering metals and ceramics.

By understanding these core functions, you can leverage the muffle furnace as a powerful tool for precise, repeatable, and clean material transformation.

Summary Table:

| Function | Key Application | Benefit |

|---|---|---|

| Ashing | Burn off organic materials for inorganic analysis | Clean, high-temperature environment ensures accurate results |

| Annealing | Heat-treat metals to modify properties | Uniform heating improves consistency and ductility |

| Sintering | Fuse powdered materials into solids | Precise temperature control below melting point for strong parts |

Unlock the full potential of your laboratory with KINTEK's advanced high-temperature furnace solutions! Leveraging exceptional R&D and in-house manufacturing, we provide diverse labs with reliable equipment like Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures precise alignment with your unique experimental needs, enhancing efficiency and accuracy. Ready to elevate your material processing? Contact us today for a tailored solution!

Visual Guide

Related Products

- 1400℃ Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- Why is re-calcination in a muffle furnace necessary for photocatalysts? Restore Efficiency via Thermal Oxidation

- What is the purpose of heating a precursor solution to 80 °C and 300 rpm stirring? Achieve High-Entropy Uniformity

- What is the core role of a muffle furnace in the synthesis of calcium oxide from eggshells? Achieve High-Purity CaO

- What is the core function of a muffle furnace in CuO nanoparticle synthesis? Achieve Precision Calcination

- What key step does a Muffle Furnace perform in the determination of mineral content in Tenebrio molitor larvae?