A laboratory box resistance furnace is chosen primarily for its ability to deliver precise, stable thermal control. In the context of mango seed drying kinetics, maintaining specific temperatures between 313K and 353K is critical. This equipment ensures a constant isothermal environment, allowing researchers to isolate temperature as a variable and accurately record moisture migration without the interference of thermal fluctuations.

The resistance furnace functions as a controlled environment that eliminates thermal variability, ensuring that observed changes in mango seed weight are solely the result of drying kinetics rather than inconsistent heating.

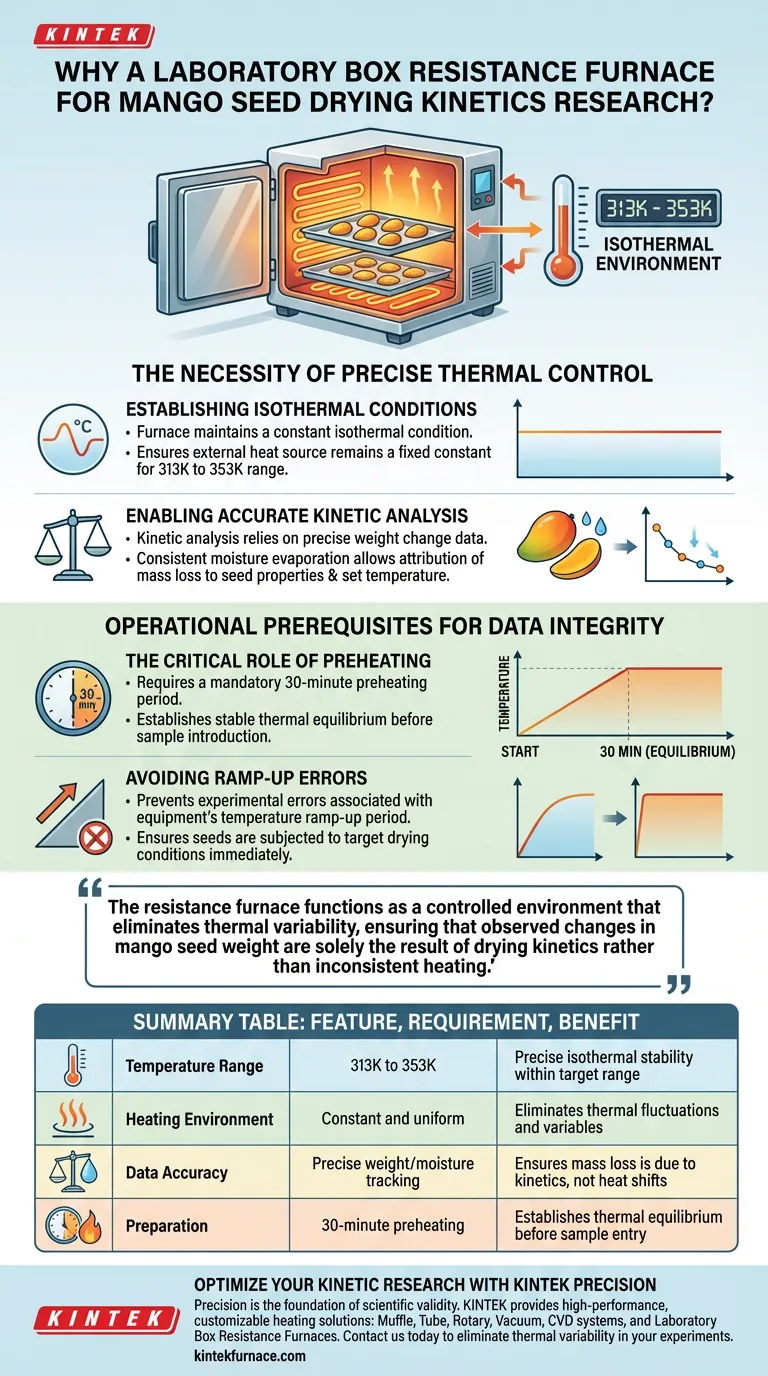

The Necessity of Precise Thermal Control

Establishing Isothermal Conditions

To study drying kinetics effectively, you must eliminate environmental variables. The box resistance furnace excels at maintaining a constant isothermal condition within the heating chamber.

This stability is vital when analyzing the impact of specific temperature gradients. By holding the temperature steady within the 313K to 353K range, the furnace ensures that the external heat source remains a fixed constant throughout the experiment.

Enabling Accurate Kinetic Analysis

Kinetic analysis relies entirely on the precision of weight change data over time.

Because the furnace ensures consistent moisture evaporation, researchers can attribute mass loss directly to the physical properties of the mango seed and the set temperature. This allows for the mathematical modeling of moisture migration with a high degree of confidence.

Operational Prerequisites for Data Integrity

The Critical Role of Preheating

While the furnace offers precision, it is not instantaneous. To achieve valid results, the equipment requires a preheating period of approximately 30 minutes.

This step is necessary to eliminate initial temperature fluctuations inside the chamber. It establishes a stable thermal equilibrium before any samples are introduced.

Avoiding Ramp-Up Errors

Placing mango seeds into a cold furnace that is actively heating up will compromise your data.

By preheating, you ensure the seeds are subjected to the target drying conditions immediately upon entry. This prevents experimental errors associated with the equipment's temperature ramp-up period, preserving the scientific integrity of the extracted kinetic parameters.

Ensuring Scientific Validity in Your Experiments

To maximize the reliability of your drying kinetics research, apply the following principles:

- If your primary focus is kinetic modeling: Ensure the furnace maintains a strict isothermal environment within the 313K to 353K range to validate moisture migration equations.

- If your primary focus is experimental accuracy: Implement a mandatory 30-minute preheating protocol to eliminate thermal ramp-up errors before introducing samples.

By isolating temperature stability as a constant, the box resistance furnace transforms variable drying patterns into measurable, scientific data.

Summary Table:

| Feature | Requirement for Mango Seed Drying | Benefit of Box Resistance Furnace |

|---|---|---|

| Temperature Range | 313K to 353K | Precise isothermal stability within target range |

| Heating Environment | Constant and uniform | Eliminates thermal fluctuations and variables |

| Data Accuracy | Precise weight/moisture tracking | Ensures mass loss is due to kinetics, not heat shifts |

| Preparation | 30-minute preheating | Establishes thermal equilibrium before sample entry |

Optimize Your Kinetic Research with KINTEK Precision

Precision is the foundation of scientific validity. Whether you are modeling moisture migration in organic materials or conducting complex thermal analysis, KINTEK provides the high-performance heating solutions you need.

Backed by expert R&D and manufacturing, KINTEK offers a comprehensive range of Muffle, Tube, Rotary, Vacuum, and CVD systems, as well as specialized laboratory box resistance furnaces. Our equipment is fully customizable to meet the unique temperature gradients and isothermal requirements of your specific lab applications.

Ready to eliminate thermal variability in your experiments? Contact us today to find your perfect furnace solution!

Visual Guide

References

- Getachew D. Gebre, J.M. Marchetti. Drying kinetics and mathematical modeling of seeds of two mango varieties at different temperatures and with different pretreatments. DOI: 10.1002/bbb.2611

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1400℃ Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

People Also Ask

- What materials are used for the cabinet of a box furnace and why? Discover Durable, Safe Steel Construction

- How does a high-temperature Muffle Furnace facilitate the conversion of precursors into spinel-type NiCo2O4?

- What conditions does a muffle furnace provide for evaluating the oxidation stability of HfOC/SiOC fiber mats?

- What are the advantages of energy efficiency and rapid heating/cooling in digital muffle furnaces? Boost Lab Productivity and Cut Costs

- What is the chamber capacity of the muffle furnace? Optimize Your Lab's Thermal Processing

- Why is it important to avoid exceeding the rated temperature of the muffle furnace? Prevent Damage and Ensure Safety

- Why is insulation quality important in muffle furnaces? Boost Efficiency and Safety in Your Lab

- How are box type electric furnaces utilized in laboratory research? Enhance Precision in Material Synthesis and Testing