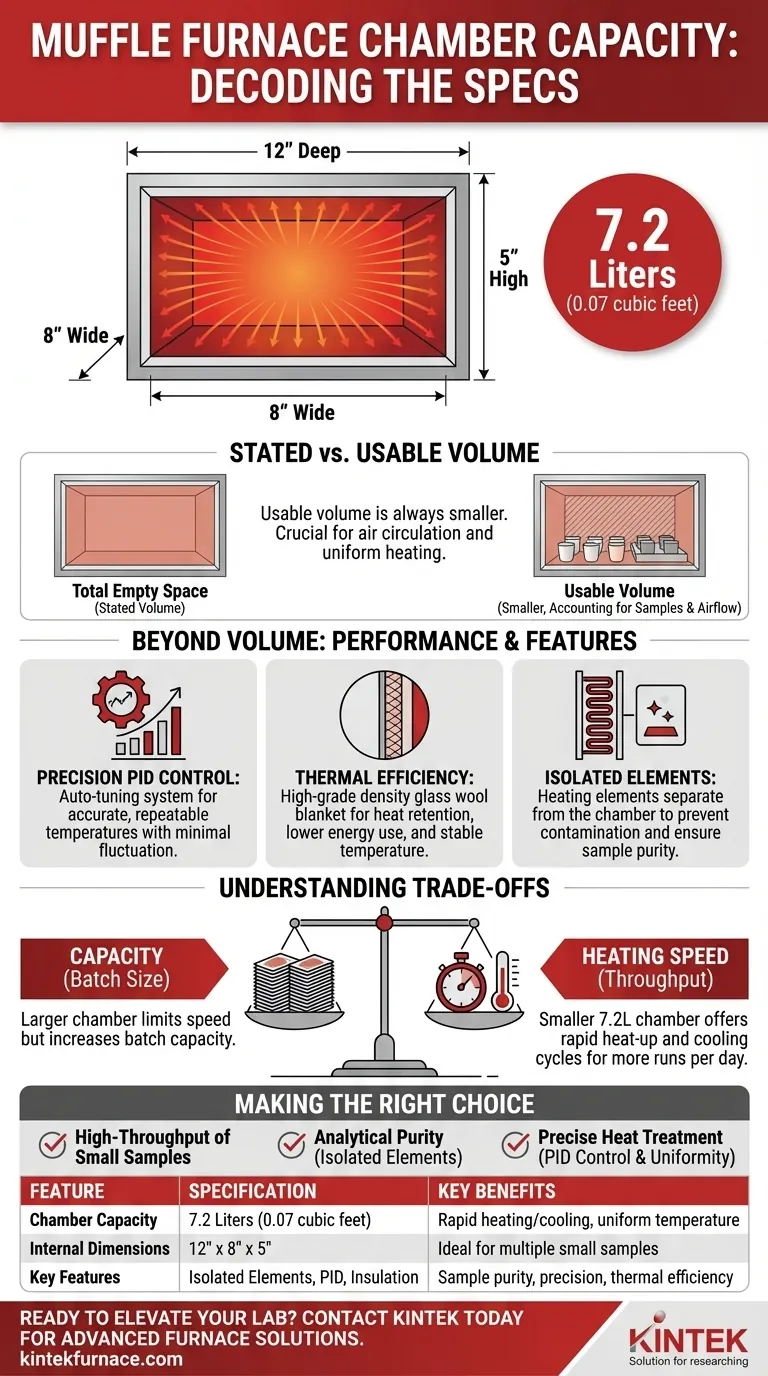

The chamber capacity of this muffle furnace is reported as 7.2 liters, or approximately 0.07 cubic feet. The internal dimensions are given as 12 inches deep, 8 inches wide, and 5 inches high, which provides a concrete understanding of the working space available for samples.

While the numbers—7.2 liters or 0.07 cubic feet—provide a starting point, they are only one part of the equation. Understanding the implications of this volume in relation to temperature control and chamber design is what truly determines if this furnace meets your specific technical requirements.

Deconstructing Chamber Capacity: More Than Just a Number

The stated volume is a raw figure. To properly evaluate the furnace, you must consider its practical application and how the chamber's design impacts your work.

Stated vs. Usable Volume

The 7.2-liter capacity represents the total empty space inside the chamber. The usable volume is always smaller. You must account for the size of your crucibles or samples, as well as the need for adequate air circulation around them to ensure uniform heating.

The Importance of Dimensions (12" x 8" x 5")

The specific shape of the chamber is often more critical than its total volume. A furnace with these dimensions (30 x 20 x 12 cm) is relatively wide and shallow, which is ideal for processing multiple small samples side-by-side but may not accommodate tall or bulky items.

Impact on Heat-Up Time and Uniformity

A smaller chamber like this one will generally heat up and cool down faster than a much larger one, improving throughput. The furnace's ability to maintain uniform temperature—a key feature for accurate results—is directly tied to its insulation and control systems working within this specific volume.

Beyond Volume: Key Features That Define Performance

A furnace's utility is defined by its thermal performance systems. The chamber capacity is simply the space where these systems operate.

Precision Temperature Control (PID)

This furnace uses an auto-tuning advanced PID controller. This is not just a simple thermostat; it's a sophisticated system that continuously calculates and adjusts power to reach a target temperature precisely and hold it with minimal fluctuation, which is essential for repeatable experiments.

Thermal Efficiency and Insulation

Effective insulation, such as the mentioned high-grade density glass wool blanket, is critical. It ensures maximum thermal efficiency by retaining heat, leading to lower energy consumption and a more stable internal temperature. It also keeps the exterior of the unit safer to the touch.

Sample Purity and Isolated Elements

A defining feature of a muffle furnace is that the heating elements are isolated from the chamber. This prevents chemical reactions or outgassing from the elements from contaminating the sample. This is non-negotiable for applications like ashing, materials analysis, or any process where sample purity is paramount.

Understanding the Trade-offs

Choosing a furnace requires balancing competing factors. What you gain in one area, you may sacrifice in another.

Capacity vs. Heating Speed

A smaller chamber, like this 7.2-liter model, offers the advantage of rapid heating and cooling cycles. While it limits batch size, it can significantly increase the number of runs you can complete in a day compared to a larger, slower furnace.

Temperature Range vs. Component Longevity

Furnaces are available with maximum temperatures ranging from 800°C to over 1600°C. Higher temperature capabilities require more robust and expensive heating elements and insulation. Operating any furnace consistently at its maximum limit will shorten the lifespan of these components.

Performance vs. Simplicity

An SSR-based heater and an advanced PID controller provide exceptional performance and thermal stability. However, they are more complex than simple on/off control systems. Ensure your team is comfortable with programming and utilizing these features to get the most out of the equipment.

Making the Right Choice for Your Application

Use your core objective to guide your evaluation of the furnace's specifications.

- If your primary focus is processing many small samples: The 7.2-liter capacity, combined with its wide and shallow dimensions, is well-suited for high-throughput work with crucibles.

- If your primary focus is analytical purity: The isolated heating elements are the most critical feature, ensuring your test results are not compromised by contamination.

- If your primary focus is precise heat treatment: The PID controller and documented temperature uniformity are more important than the raw volume.

Ultimately, selecting the right muffle furnace is about matching the chamber's physical capacity with the thermal performance required to achieve reliable and repeatable results.

Summary Table:

| Feature | Specification |

|---|---|

| Chamber Capacity | 7.2 liters (0.07 cubic feet) |

| Internal Dimensions | 12" deep x 8" wide x 5" high |

| Key Benefits | Rapid heating/cooling, uniform temperature, sample purity |

| Ideal For | High-throughput small samples, precise heat treatment, analytical purity |

Ready to elevate your laboratory's capabilities? At KINTEK, we specialize in advanced high-temperature furnace solutions tailored to your unique needs. Leveraging exceptional R&D and in-house manufacturing, our product line—including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems—is designed for precision and reliability. With strong deep customization capabilities, we ensure our furnaces meet your exact experimental requirements, boosting efficiency and accuracy. Don't settle for less—contact us today to discuss how we can support your research and development goals!

Visual Guide

Related Products

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1400℃ Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- What is the primary function of a muffle furnace for BaTiO3? Master High-Temp Calcination for Ceramic Synthesis

- What metals cannot be heated by induction? Understanding Material Suitability for Efficient Heating

- What environmental conditions are critical for SiOC ceramicization? Master Precise Oxidation & Thermal Control

- What is the role of a muffle furnace in the study of biochar regeneration and reuse? Unlock Sustainable Water Treatment

- What substances are prohibited from being introduced into the furnace chamber? Prevent Catastrophic Failure