In a muffle furnace, insulation quality is the single most important factor determining its energy efficiency, heating speed, and operational safety. High-quality insulation, typically made of high-purity ceramic fibers, directly reduces energy waste by preventing heat from escaping and keeps the exterior of the furnace cool, protecting both users and the laboratory environment.

A muffle furnace's value is not defined by its maximum temperature, but by its ability to efficiently and safely maintain that temperature. The insulation is the core component that dictates this performance, directly impacting everything from your utility bill to the safety of your lab personnel.

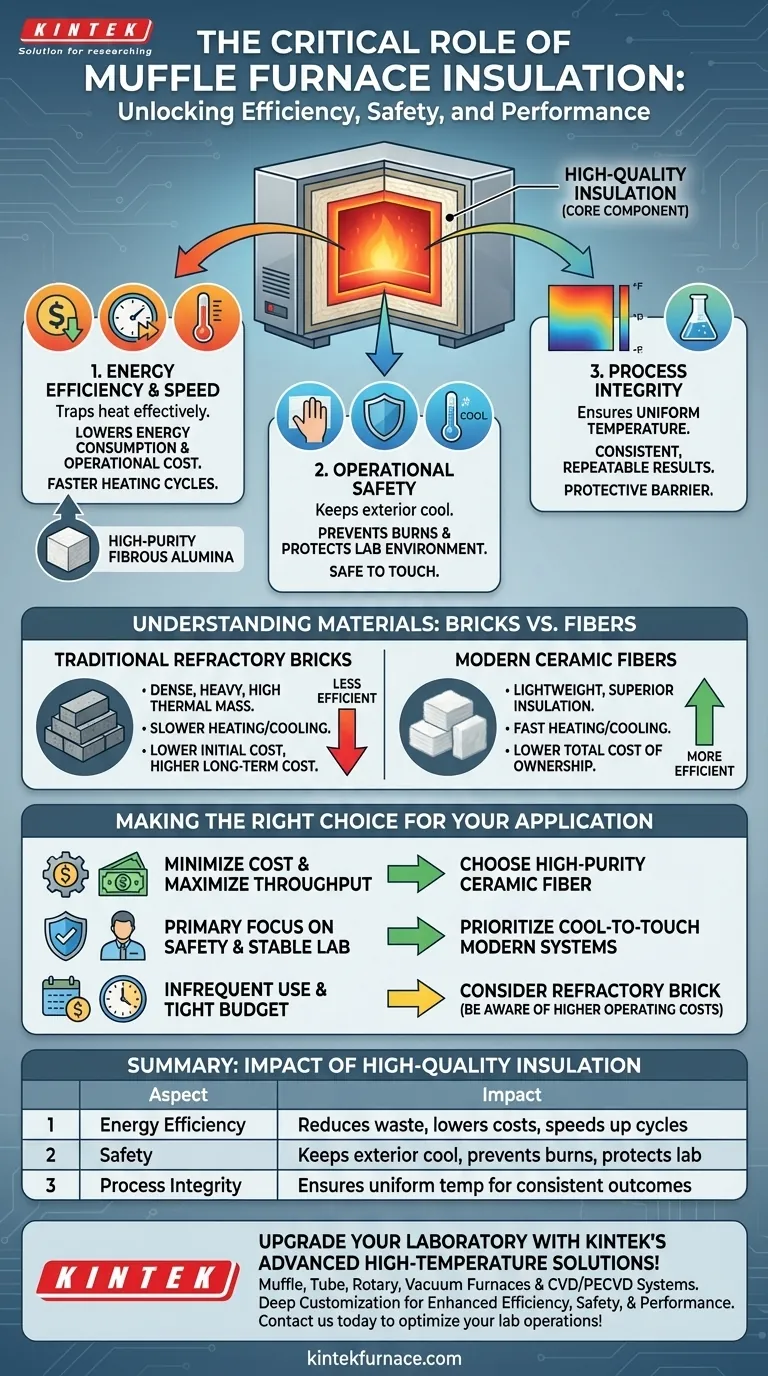

The Three Pillars of Insulation Performance

The quality of a furnace's insulation has a direct and measurable impact on three critical areas: operational cost, user safety, and the integrity of the heating process itself.

Maximizing Energy Efficiency and Speed

High-purity fibrous alumina insulation is engineered to be an exceptional thermal barrier. By effectively trapping heat within the main chamber, it dramatically reduces the amount of energy required to both reach and maintain a target temperature.

This efficiency translates into two key benefits. First, it lowers energy consumption, leading to significant cost savings over the furnace's lifetime. Second, it increases the heating speed, as less thermal energy is wasted to the surrounding environment, allowing for faster process cycles.

Ensuring Operational Safety

Perhaps the most critical function of insulation is preventing the furnace's outer steel body from becoming dangerously hot. A furnace operating at 1000°C internally should remain safe to touch externally.

Poor insulation leads to an excessively hot exterior, creating a severe burn risk for operators. It also radiates significant heat into the lab, increasing the ambient temperature and potentially damaging nearby sensitive equipment or materials. Modern designs pair quality insulation with a double-layer steel structure and cooling fans to guarantee a safe exterior.

Guaranteeing Process Integrity

Effective insulation ensures a uniform temperature is maintained throughout the chamber. This is essential for achieving consistent, repeatable results, as it eliminates hot and cold spots that could affect the sample.

Additionally, in some designs, the fireproof ceramic insulation serves as a protective barrier, or "muffle," that isolates the heating elements from corrosive vapors and gases released by the samples during heating.

Understanding the Materials: Bricks vs. Fibers

Muffle furnaces primarily use one of two types of insulation materials, which largely defines their performance characteristics.

Traditional Refractory Bricks

Refractory bricks are a dense, heavy, and durable insulation material. While effective at containing high temperatures, they represent an older form of furnace technology. Their high thermal mass means they absorb a significant amount of heat, making them less energy-efficient and slower to heat up and cool down.

Modern Ceramic Fibers

Modern, high-performance furnaces use insulation made from high-purity fibrous alumina. This lightweight material has superior insulating properties, meaning it prevents heat escape far more effectively than bricks. This is the key material behind furnaces that boast high energy efficiency, fast heating rates, and cool exterior surfaces.

Understanding the Trade-offs

Choosing between insulation types involves balancing upfront cost against long-term performance and operational needs.

Cost vs. Lifetime Value

A furnace built with traditional refractory bricks often has a lower initial purchase price. However, a furnace with modern ceramic fiber insulation will almost always have a lower total cost of ownership due to significant energy savings and increased throughput from faster heating cycles.

Thermal Mass and Workflow

The high thermal mass of refractory bricks means a brick-lined furnace will take much longer to cool down. In a busy lab requiring frequent access to samples, a lightweight ceramic fiber furnace offers a significant workflow advantage with its faster heating and cooling cycles.

Making the Right Choice for Your Application

Your choice of furnace should be guided by your specific operational priorities and budget.

- If your primary focus is minimizing operational costs and maximizing throughput: Choose a furnace with high-purity ceramic fiber insulation for its superior energy efficiency and fast heating rates.

- If your primary focus is safety and a stable lab environment: Prioritize furnaces with modern ceramic fiber insulation systems that are explicitly designed for a cool-to-the-touch exterior.

- If your work involves infrequent use on a tight budget: A traditional refractory brick furnace may be a viable entry point, but be prepared for its higher energy consumption and slower performance.

Ultimately, understanding the role of insulation transforms your decision from a simple purchase to a strategic investment in your laboratory's efficiency and safety.

Summary Table:

| Aspect | Impact of High-Quality Insulation |

|---|---|

| Energy Efficiency | Reduces energy waste, lowers operational costs, and speeds up heating cycles |

| Safety | Keeps exterior cool, prevents burns, and protects lab environment |

| Process Integrity | Ensures uniform temperature for consistent, repeatable experimental outcomes |

Upgrade your laboratory with KINTEK's advanced high-temperature furnace solutions! Leveraging exceptional R&D and in-house manufacturing, we offer Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures we precisely meet your unique experimental needs, delivering enhanced efficiency, safety, and performance. Contact us today to discuss how we can optimize your lab operations!

Visual Guide

Related Products

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1400℃ Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- What is the primary function of a muffle furnace for BaTiO3? Master High-Temp Calcination for Ceramic Synthesis

- What is the role of a muffle furnace in the study of biochar regeneration and reuse? Unlock Sustainable Water Treatment

- How do you clean a muffle furnace? Ensure Peak Performance and Longevity

- Why is a high-performance muffle furnace required for the calcination of nanopowders? Achieve Pure Nanocrystals

- Can a muffle furnace be used for pyrolysis? Unlock Precise Thermal Decomposition